Integral microporous filtering method and device for water treatment

A technology of microporous filtration and water treatment, which is applied in the direction of osmosis/dialysis water/sewage treatment, etc., which can solve the problems of poor membrane cleaning, poor backwash regeneration ability, and short membrane service life, etc., and achieve membrane treatment The process is simple and practical, saving supporting costs and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

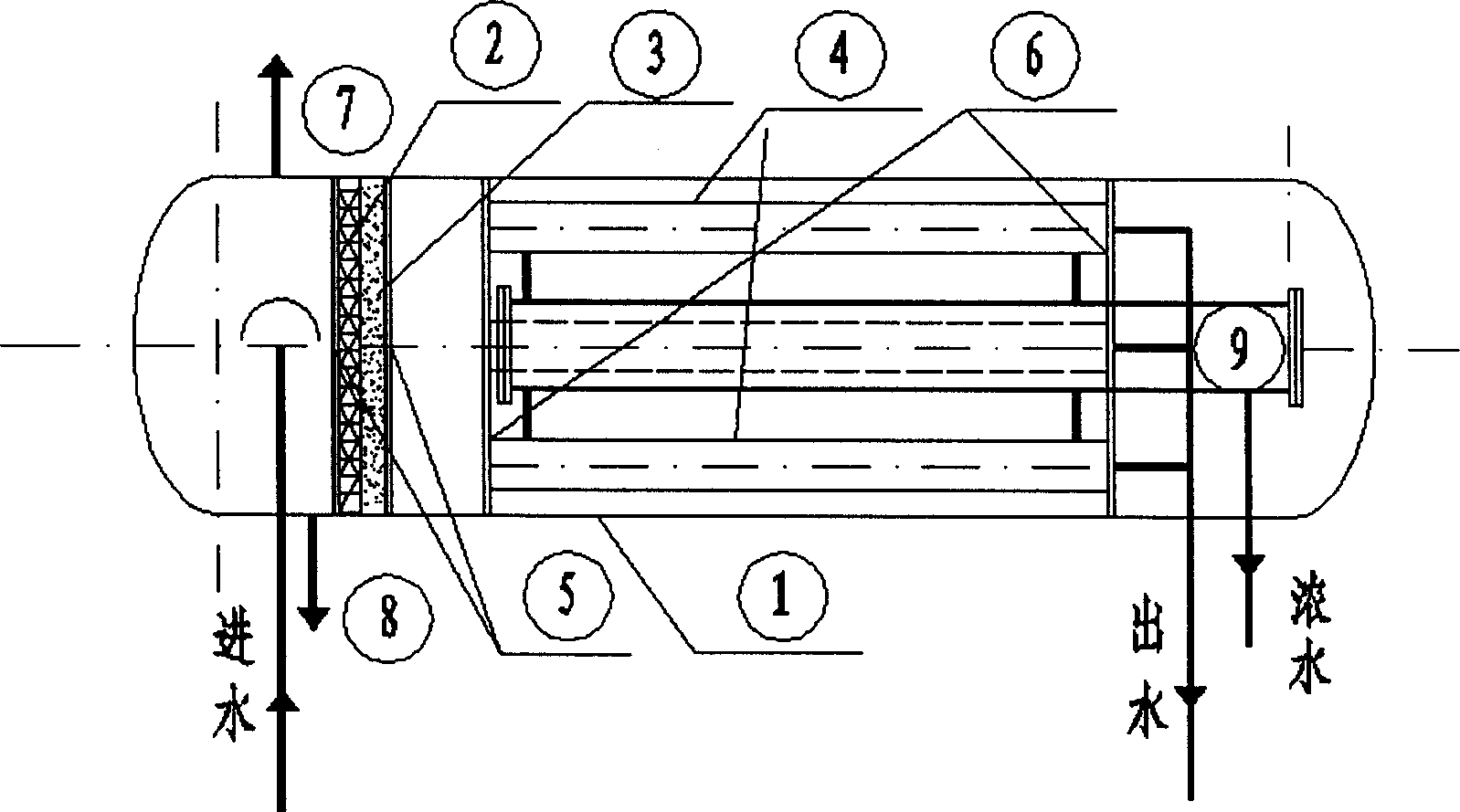

[0036] Refer to the following figure 1 The present invention will be described in detail.

[0037] like figure 1 As shown, in a horizontal closed container 1, an activated carbon fiber felt filter layer 2, a 5-micron polyethylene filter plate 3, and a polyvinylidene fluoride with a pore size of 0.2-0.4 micron are packaged sequentially from the water inlet to the water outlet. Hollow fiber membrane module4. The activated carbon fiber felt filter layer 2 and the 5-micron polyethylene filter plate 3 are fixed between two perforated water distribution steel plates 5, and the perforated water distribution steel plates 5 are fixed in the closed container 1. The polyvinylidene fluoride hollow fiber membrane modules 4 are arranged in a horizontal tubular arrangement and fixed on a fixing plate 6 with holes, and the fixing plate 6 is fixed in the closed container 1 . The upper part of the water inlet end of the closed container 1 is provided with an interface 7 for removing floating o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com