Method of determing cold rolling expansion feeding speed

A technology of feed speed and cold rolling, which is applied in the field of ring cold rolling processing, can solve the problems of high cost, long process cycle of new products, lack of scientific basis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

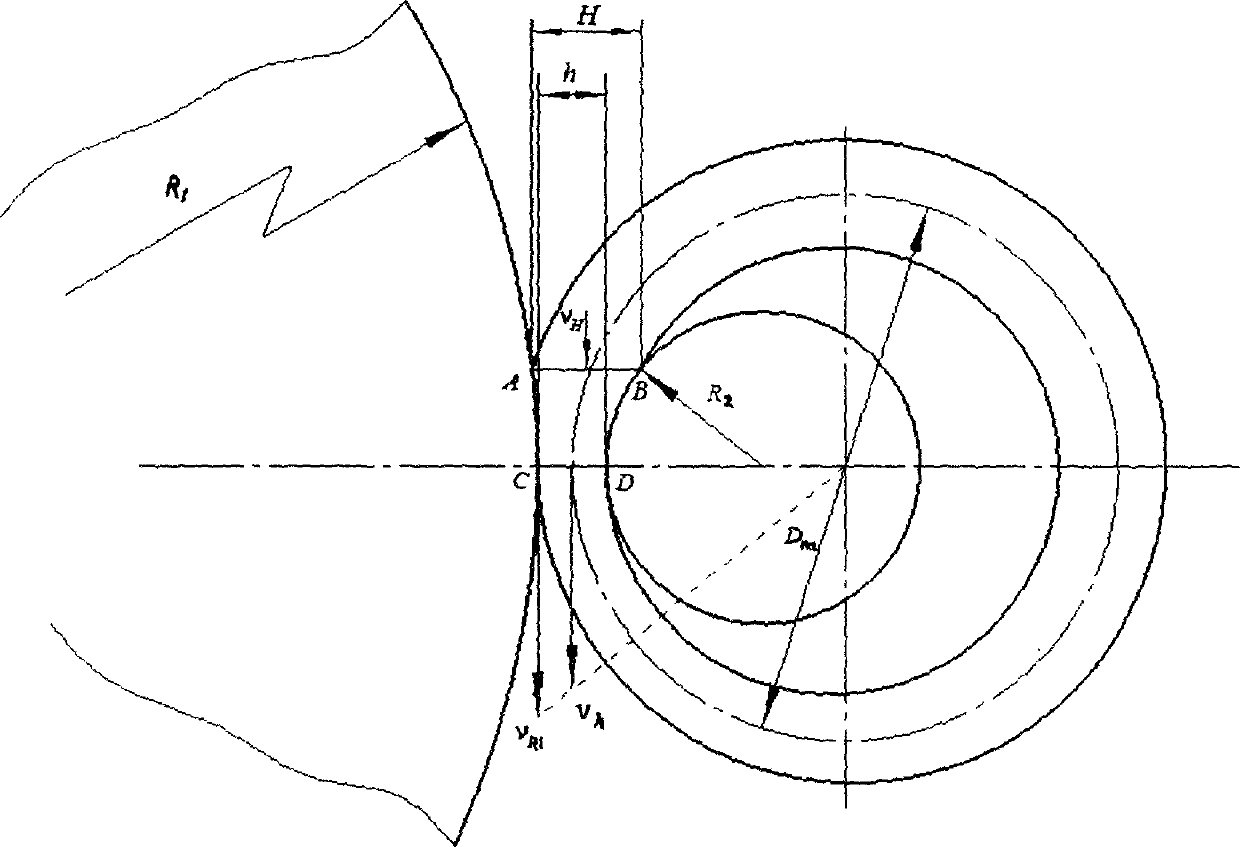

[0081] The blank size is: R 0 =33.6mm, r 0 =23.9mm, radius R of the main roller 1 =103.61mm, core roll radius R 2 =17.14mm, peripheral speed v of the main roller R1 =1583.3mm / s (speed 146r / min), the wall thickness of the ring blank is 9.7mm, the wall thickness of the finished ring is 7.7mm, the cold rolling expansion friction coefficient μ=0.1, β=arctanμ.

[0082] Substituting the above data into equations (17)-(20), the extreme value of the diameter growth rate is obtained, D g min = 1.27 mm / s , D g max = 8.63 mm / s Substituting the two extreme values into formula (13) respectively, two functions of the feed speed with respect to the wall thickness of the rolling ring are obtained, and the images of these two fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com