Circuit substrate manufacturing method and system, substrate used for the same, and circuit substrate using the same

A production method and circuit board technology, applied in circuits, printed circuits, printed circuits, etc., can solve problems such as impossible realization, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

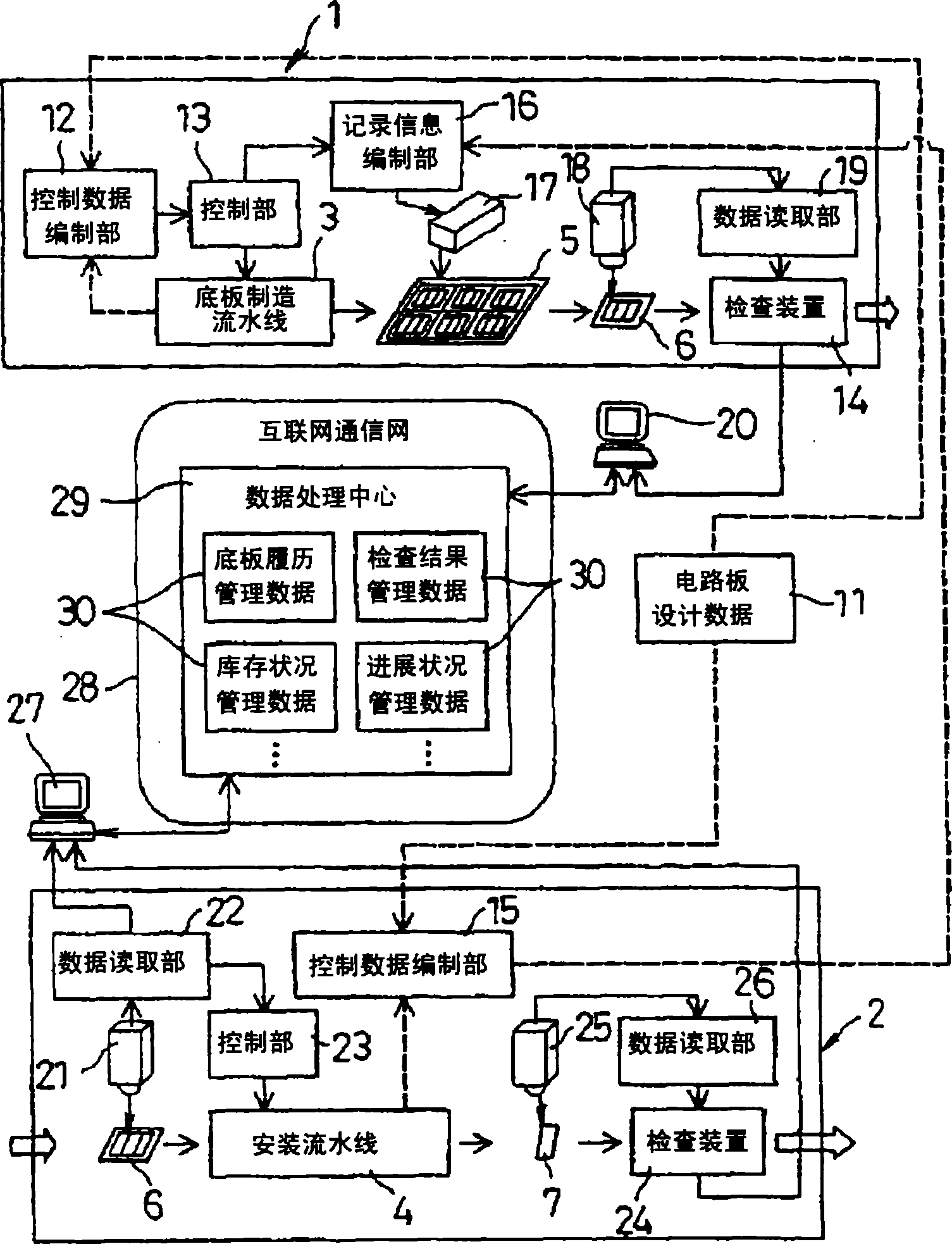

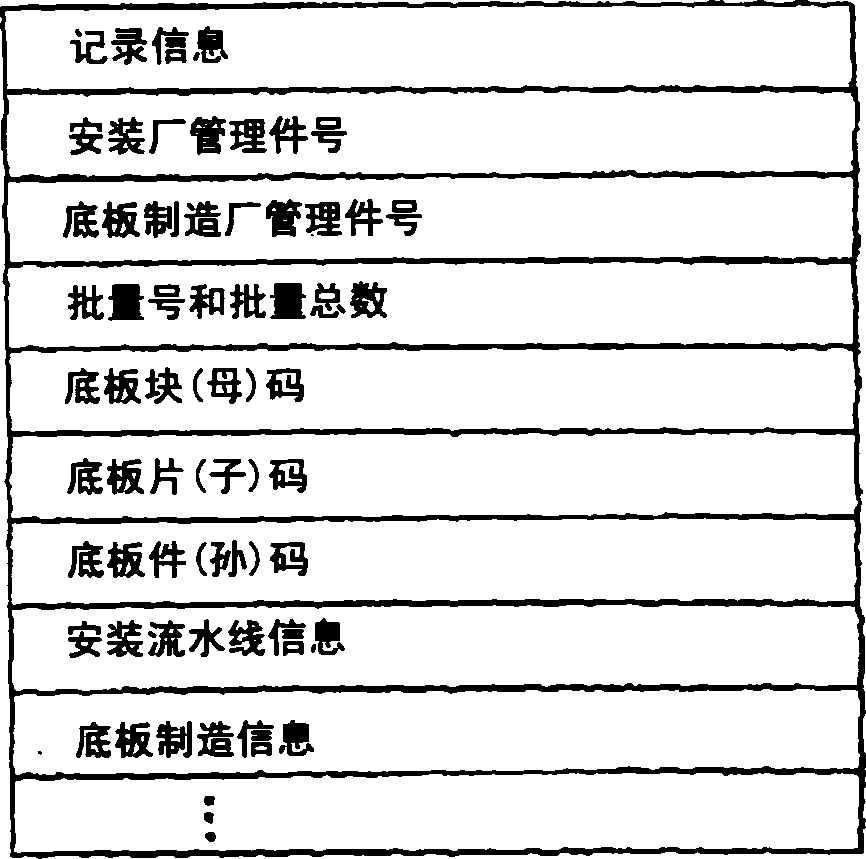

[0022] Below, refer to Figure 1 to Figure 3 A production method and system implementation of a circuit board of the present invention are described.

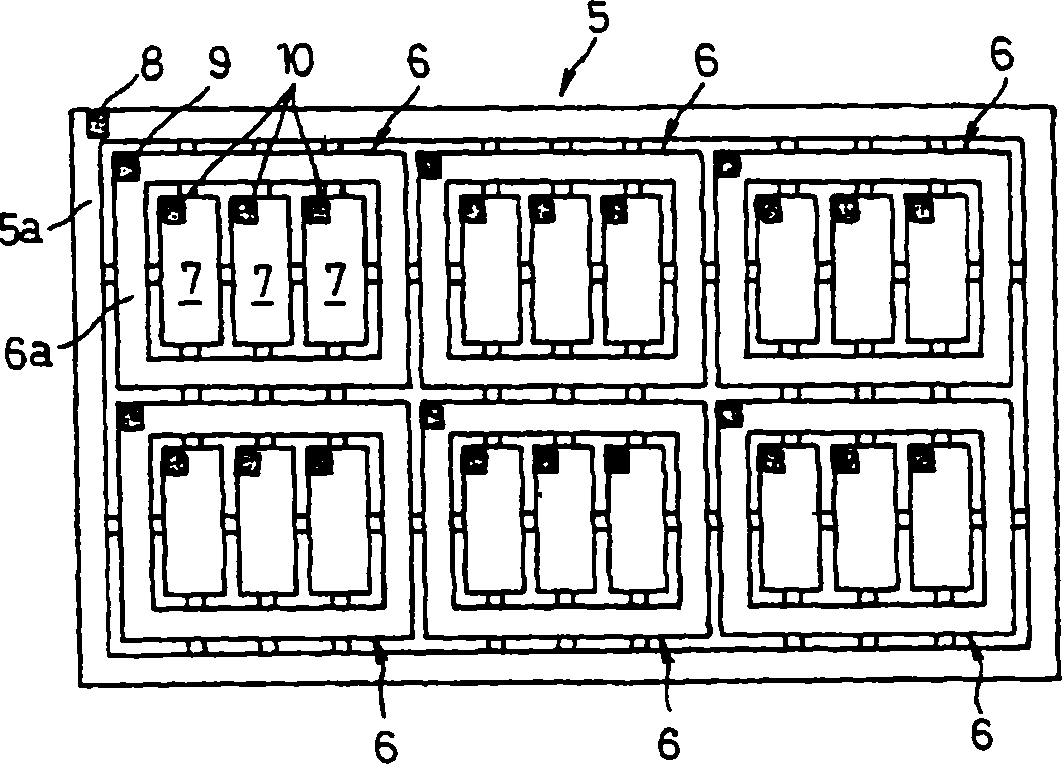

[0023] like figure 1 As shown, in the present embodiment, in the backplane manufacturing line 3 of the backplane manufacturing plant 1, a large multi-piece backplane (hereinafter referred to as a backplane block) 5 in which a plurality of backplanes are arranged is manufactured, and is divided into a plurality of pieces arranged to become each circuit board. The bottom plate (hereinafter referred to as the bottom plate piece) 6 of the bottom plate (hereinafter referred to as the bottom plate piece) is circulated to the installation plant 2 and supplied to the plant, and the installation line 4 of the installation plant 2 installs the required base plate pieces 7 of the bottom plate piece 6. The electronic components are further divided into respective base parts 7 to produce circuit boards.

[0024] like figure 2As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com