Bread improving agent and breads containing the same

A technology of bread improver and improver, which is applied in dough processing, baked food with modified ingredients, baking, etc. It can solve problems such as unknown effects, achieve excellent fermentation taste, and reduce the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

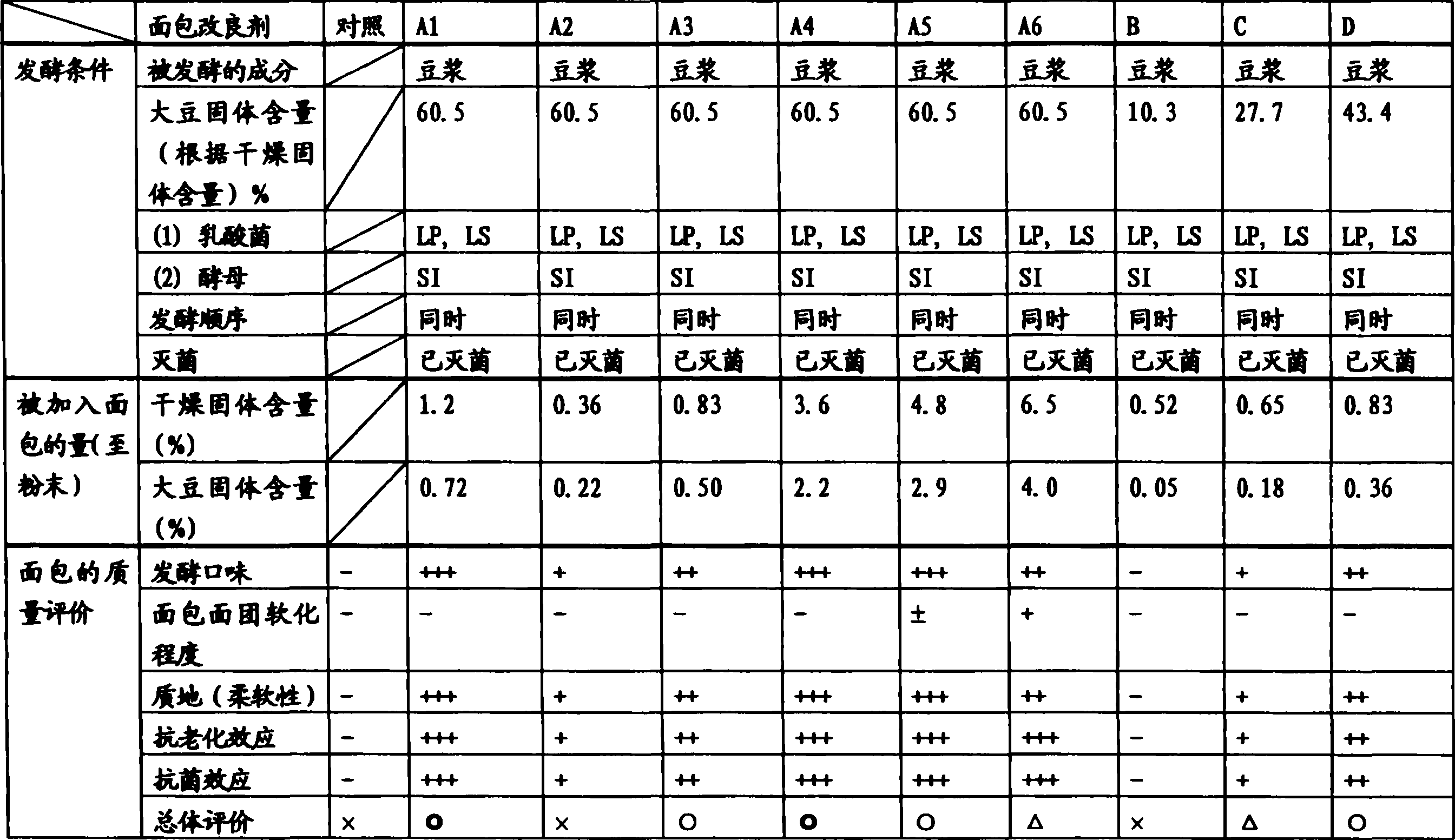

Examples

preparation example Construction

[0044] The yeast used for the preparation of fermented soybean protein may be those commonly used as a leavening agent, and is not particularly limited. Yeast can be used alone or in combination of two or more, and the fermentation temperature and time can be selected according to the specific strains of the yeast and the lactic acid bacteria combined with it.

[0045] Yeast strains are not particularly limited, but examples of yeast include yeasts derived from sour leaveners as a class of leavening agents, such as San Francisco sour leavener, rye sour Yeasts for leavening agents and panetone leavening agents, as well as yeasts from hops yeast, brewer's yeast, sake yeast, fruit yeasts such as grape and apple yeasts. Sour leavening agents and the like containing yeast and lactic acid bacteria can complete fermentation without adding additional lactic acid bacteria, so they are preferable in terms of operation steps. Examples of the yeast derived from the acid leavening agent i...

Embodiment 1

[0073] Bread improver using panetone leavening agent

[0074] Commercially available soy milk (9% by weight solids) was heat sterilized at 142°C for 5 seconds and cooled to 30°C. In 80 parts of soybean milk, add 2 parts of panetone leavening agent solution (comprising panex Lactobacillus, San Francisco Lactobacillus and exiguus yeast, and have a solid content of 30% by weight (manufactured by PANEX Co., Ltd.), 2 parts of Glucose, 1 part of flour, 0.5 part of water-soluble soybean polysaccharide (SOYAFIVE, manufactured by Fuji Oil Co., Ltd.), 0.5 part of skimmed milk powder, 0.1 part of soybean peptide (HINUTE, manufactured by Fuji Oil Co., Ltd.), water was added to make The total amount was made into 100 parts, and then fermented in an oven at 30° C. until the pH reached 4.4. The fermentation time is about 24 hours. Subsequently, the mixture was cooled to 7° C. using a plate type heat exchanger to prepare fermented soybean protein. Homogenized under a pressure of 100 kg and...

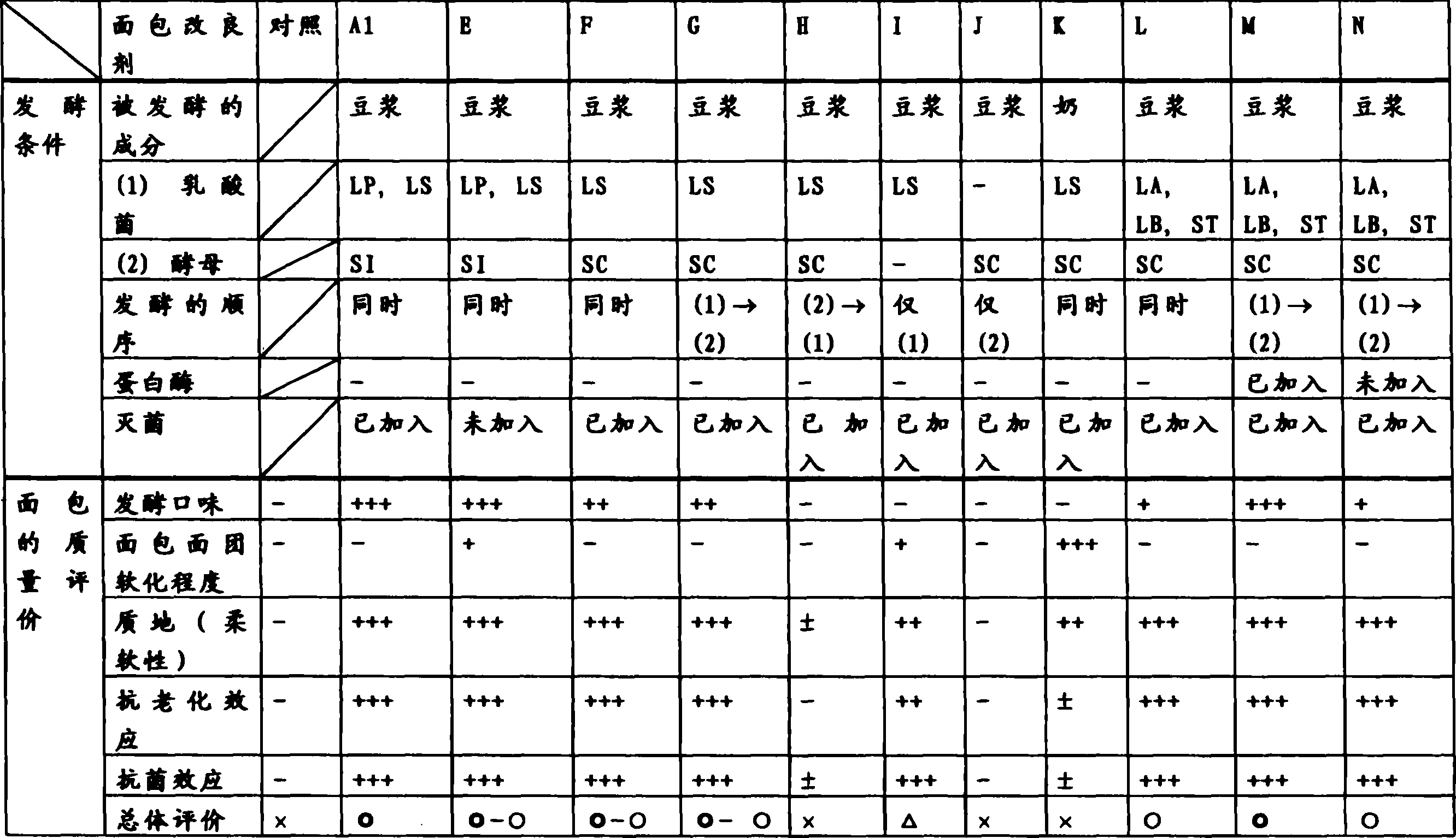

Embodiment 2

[0077] Use of fermented soy protein without sterilization

[0078] Bread improver [E] was prepared in the same manner as improver [A] in Example 1, except that the fermented soybean protein was not sterilized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com