Hydrophobic window screening and filtering net preparation method

A filter screen and window screen technology, which is applied in textiles and papermaking, textile material processing, fabrics, etc., can solve the problems of window screens without hydrophobic function, entry into the room, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

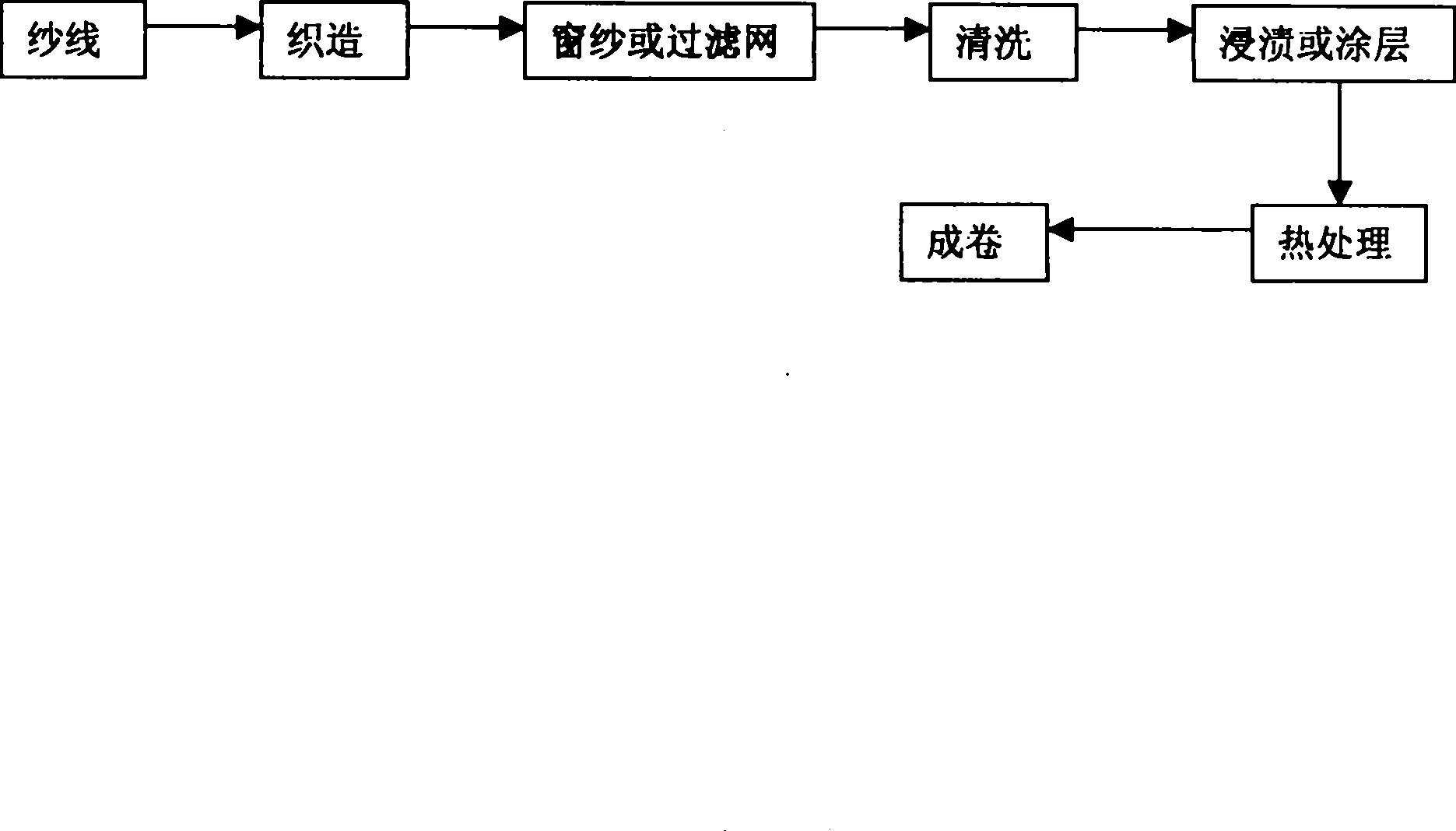

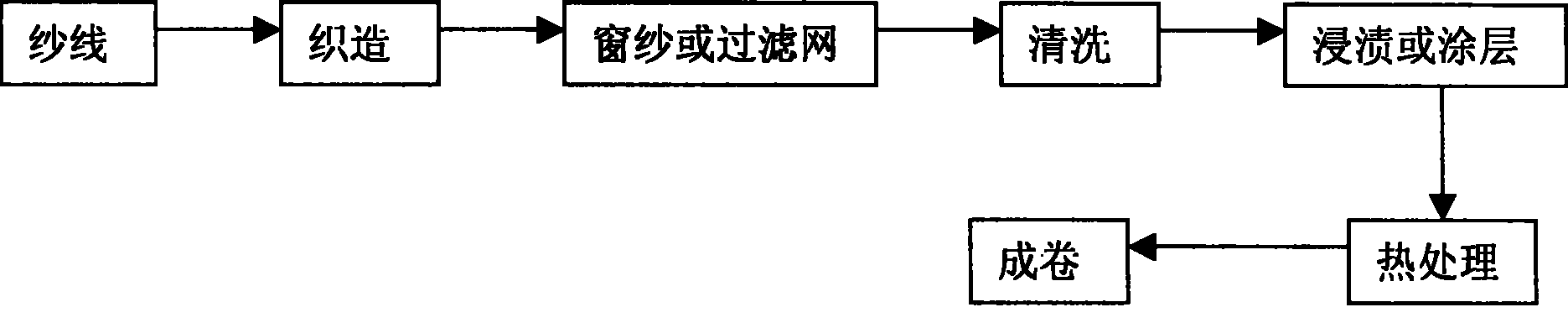

Method used

Image

Examples

Embodiment 1

[0009] Using 0.5mm stainless steel single fiber as raw material, the fiber raw material is woven into 24-mesh window screen by textile machine. After cleaning the window screen with detergent and water, the hydrophobic treatment is carried out by dipping method, and the window screen is soaked in polytetrafluoroethylene hydrophobic agent AG- In 700, treat at room temperature for 1.5 hours, the thickness of the hydrophobic agent coating reaches 50 μm, heat treatment after dipping, the temperature is 250 ° C, and the time is 15 minutes. After drying, it is rolled into a finished product.

Embodiment 2

[0011] 80 glass fibers are used as raw materials, and the fiber raw materials are woven into 40-mesh window screens with arrow shaft machines. After cleaning the window screens with detergent and water, hydrophobic treatment is carried out by coating method. Silicone hydrophobic agent TS-2001 Coated on the surface of the window screen fiber, the thickness of the hydrophobic agent coating reaches 30 μm, and heat treatment is carried out after coating, the treatment temperature is 180 ° C, and the time is 30 minutes. After drying, it is rolled into a finished product.

Embodiment 3

[0013] Using 10μm stainless steel fiber as raw material, the fiber raw material is woven into a 1000-mesh filter screen with an air-jet loom. After the filter screen is cleaned with detergent and water, the hydrophobic treatment is carried out by dipping method, and the filter screen is soaked in polytetrafluoroethylene hydrophobic agent. In AG-70, treat at room temperature for 10 minutes, and the thickness of the hydrophobic agent coating reaches 0.5 μm. After dipping, heat treatment is carried out at a temperature of 350 ° C for 5 seconds. After drying, it is rolled into a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com