Signal switching apparatus of static multi-point strainmeter

A signal switching and strain gauge technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, and the use of applied stable tension/pressure to test the strength of materials, etc. and other problems to achieve the effect of overcoming thermal drift, increasing switching speed, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

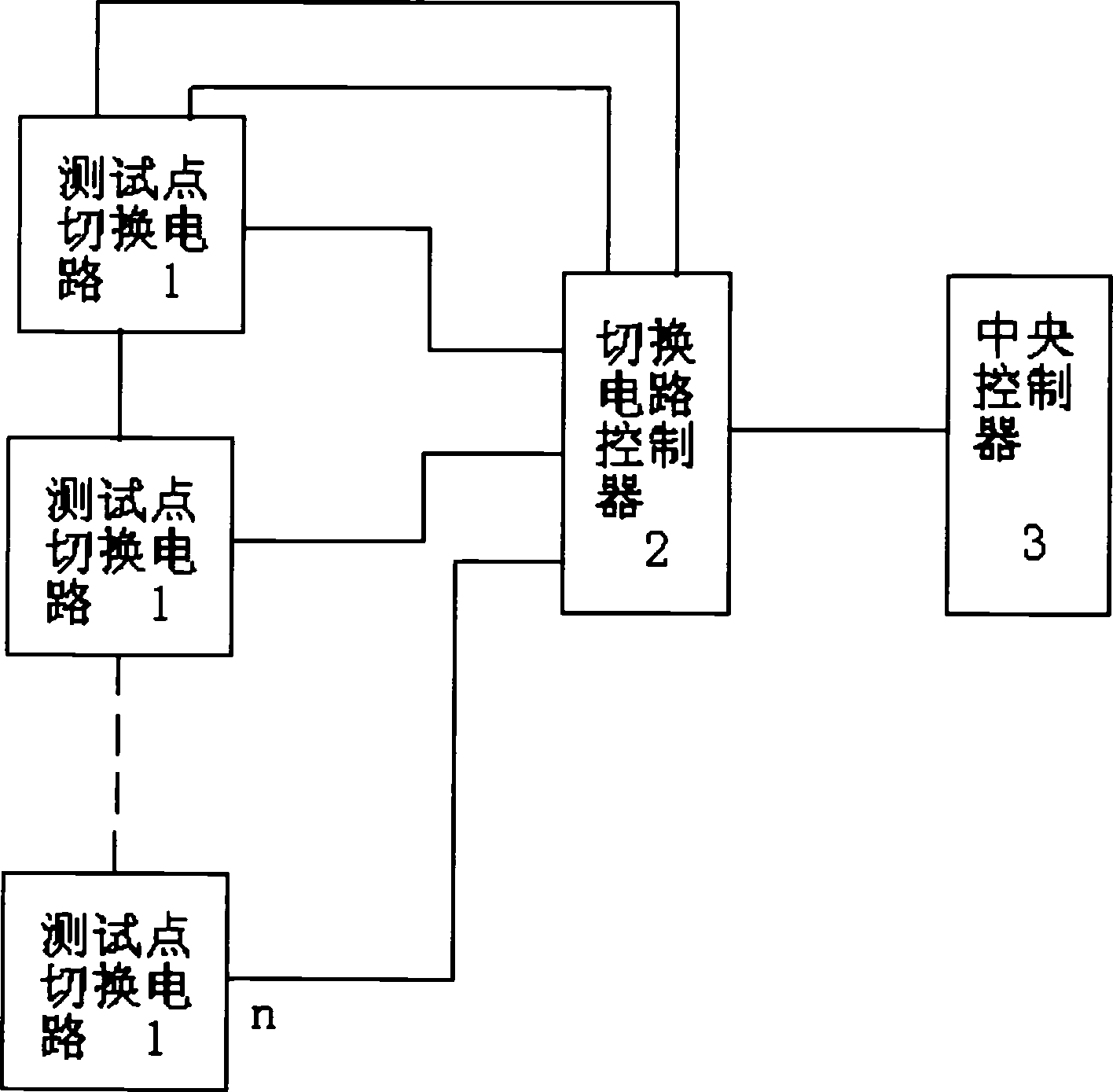

[0013] Such as figure 1 Shown: switching device of the present invention comprises:

[0014] Several test point switching circuits 1;

[0015] The switching controller 2 is bidirectionally connected to several test point switching circuits, and is used to switch the working states of several test point switching circuits.

[0016] The central controller 3 is bidirectionally connected with the switching controller 2 and is used to control the output signal of the switching controller.

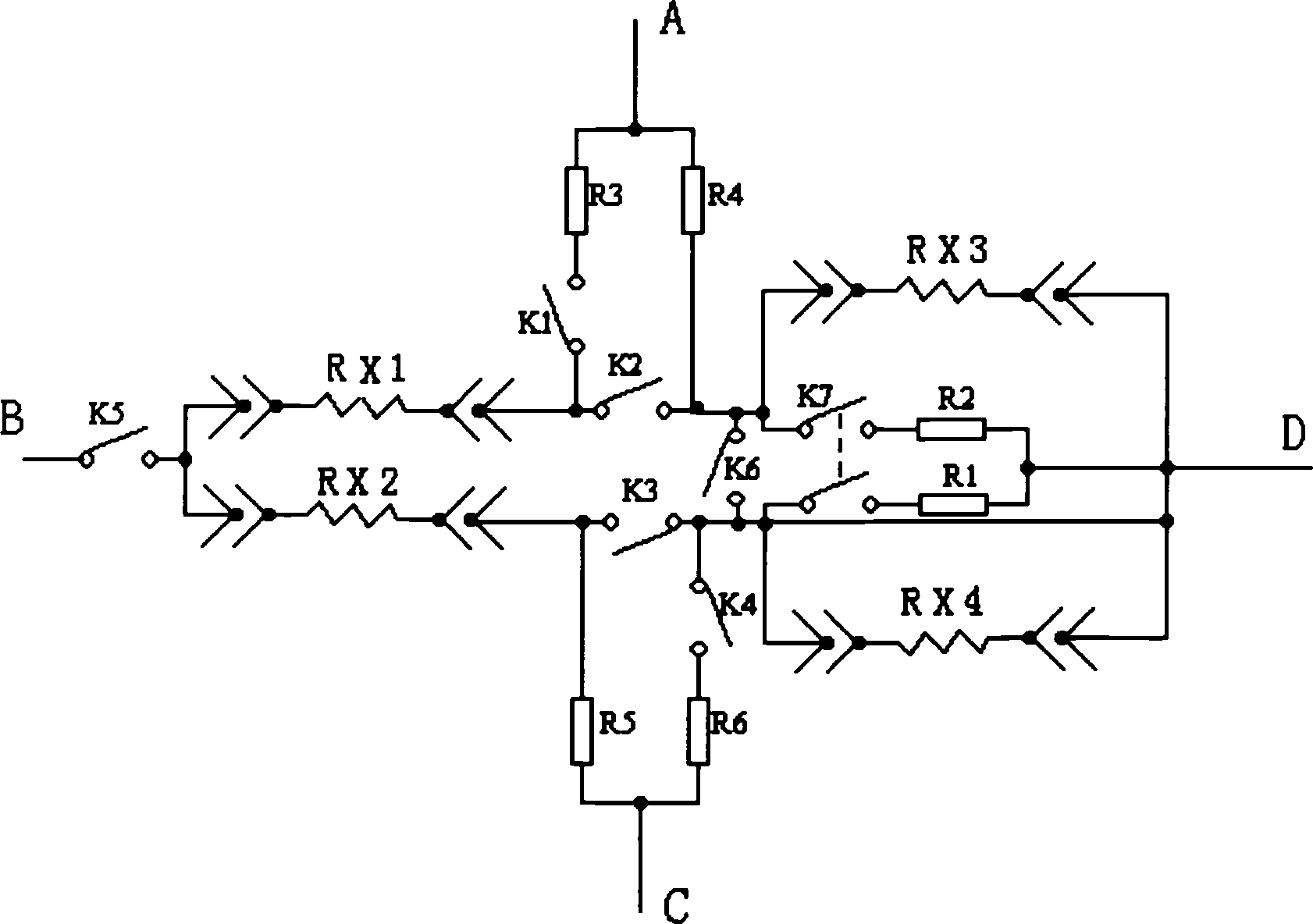

[0017] Each test point switching circuit 1 includes: a first input terminal A, a second input terminal C, a first output terminal B, a first output terminal D, and 7 relays (first relay K1, second relay K2, The third relay K3, the fourth relay K4, the fifth relay K5, the sixth relay K6, the seventh relay K7), 6 fixed resistors (the first fixed resistor R1, the second fixed resistor R2, the third fixed resistor R3, the Four fixed resistors R4, fifth fixed resistor R5, sixth fixed resistor R6),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com