Process for the production of pigment composition, colored composition for color filter obtained by said process, and color filter

A technology of pigments and mixtures, applied in the direction of instruments, optical filters, organic dyes, etc., can solve the problems of display brightness ratio (low contrast)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

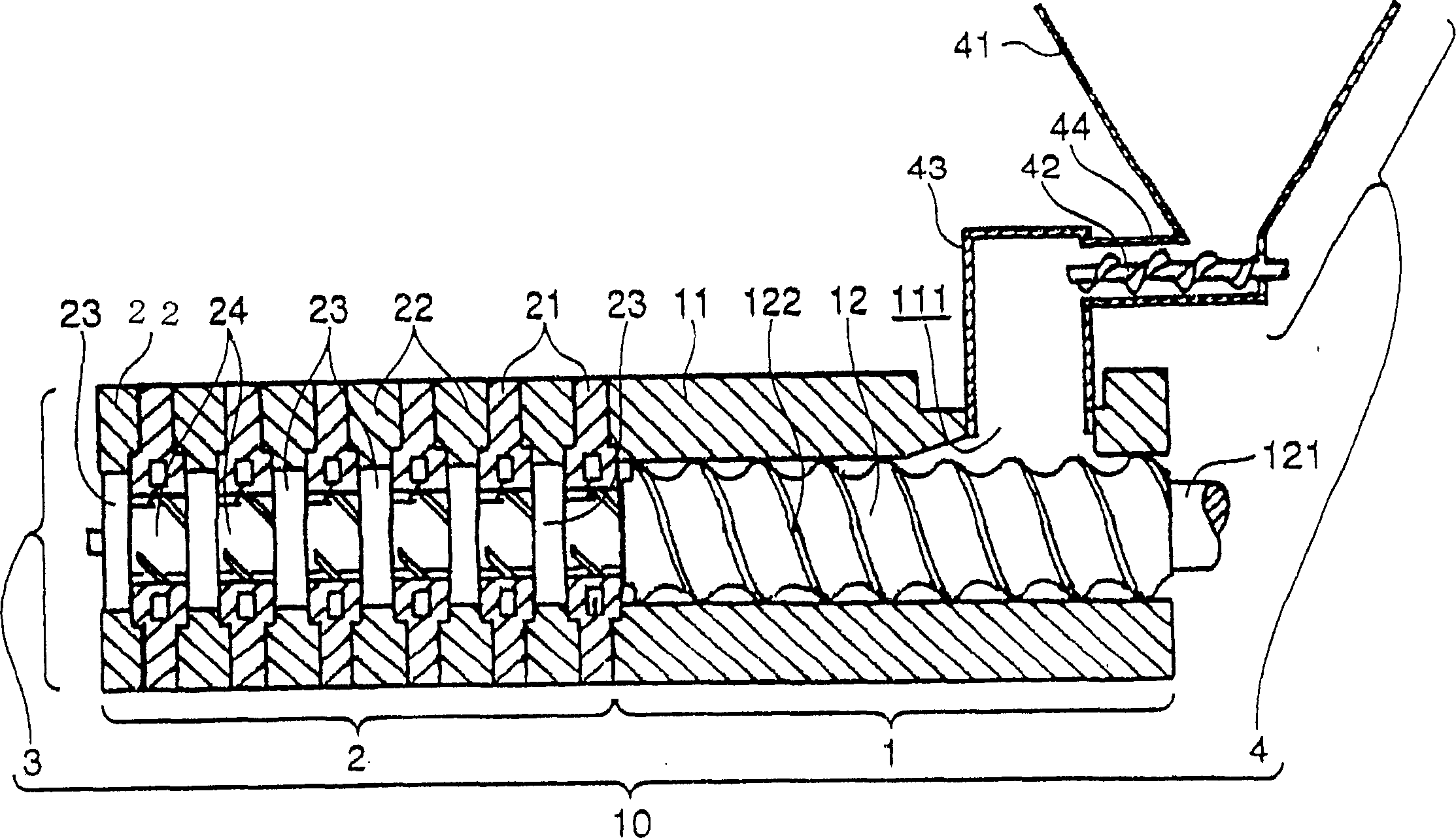

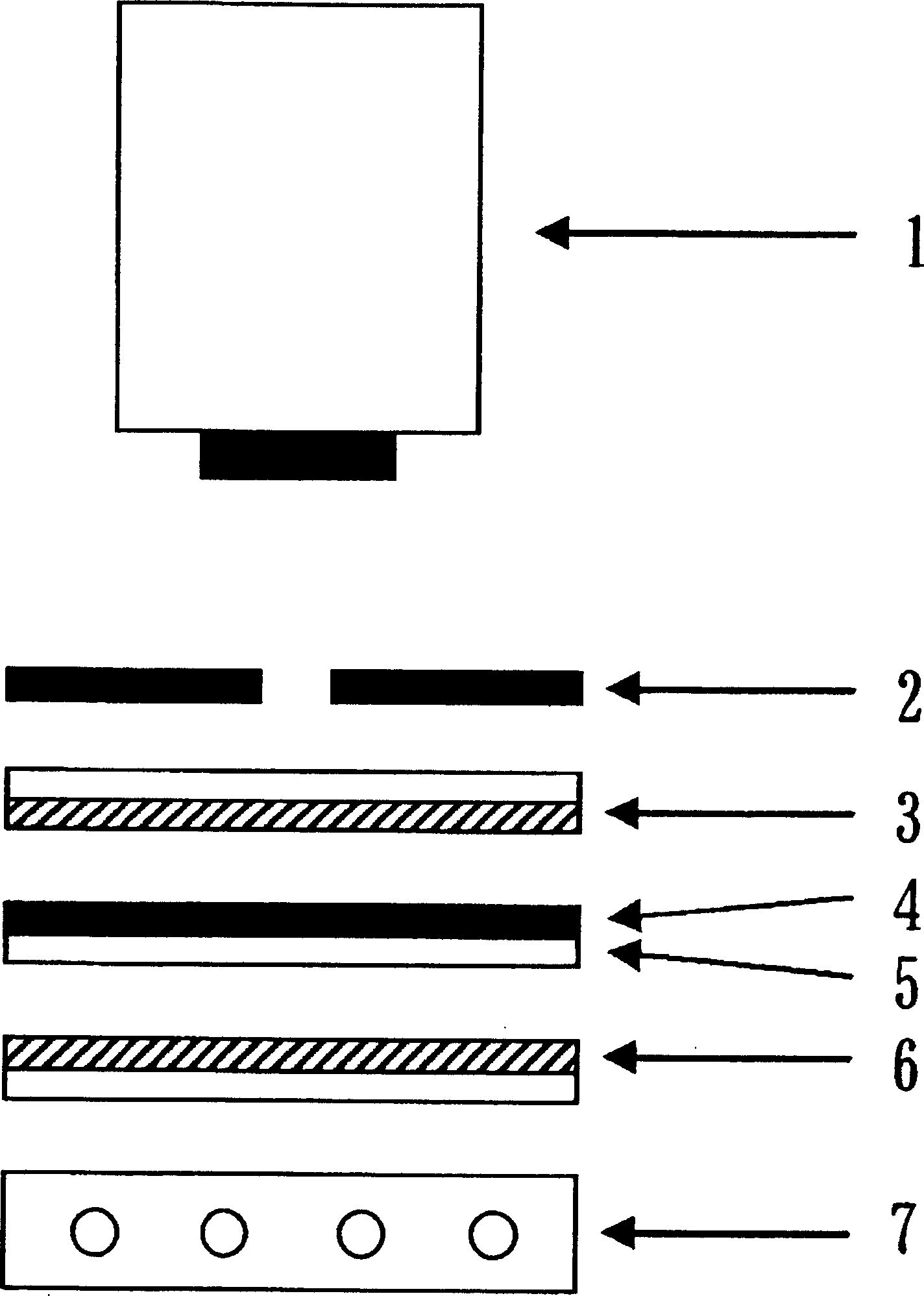

[0254] Using a conversion mixer (provided by Asada Iron Works.Co., LTD), 100 parts of Blue 15 (T-95 crude blue, provided by ZHUHAI TOYO INK CO., LTD) as organic pigments, and 600 parts of sodium chloride as water-soluble The natural inorganic salt, 100 parts of diethylene glycol as the water-soluble organic liquid and 5 parts of rosin resin (Ester gum AT, provided by Arakawa Chemical Industries, Ltd.) as the resin were premixed almost uniformly for 5 minutes. Pass the resulting mixture through a screw-type metering feeder ( figure 1 The metering feeder part 4) in the is supplied to the continuous kneader 10 ("Miracle K.C.K.-type 42", provided by Asada Iron Works. Co., LTD). The continuous kneader 10 has a feeding part screw with a diameter of 120 mm(R) and eight sets of kneading parts composed of a fixed disk and a rotating disk. The continuous kneader 10 was operated at a kneaded composition extrusion amount of 21 kg / hour at a spindle rotation number of 50 rpm and a kneading tem...

Embodiment 2 to 4

[0268] Except that synthetic rosin (Dymerex resin, provided by Rika Hercules), disproportionated rosin (Rondis R, provided by Arakawa Chemical Industries, Ltd.) and hydrogenated rosin (Staybelite resin, provided by Rika Hercules) were used instead of resins, the same as the examples 1 The pigment composition is obtained in the same manner. Table 1 shows the electric power consumption required for kneading and the ΔL of the coated product * value.

[0269] ΔL of each coating * All are larger than the values of Comparative Examples 1 to 4, and each coated product has good transparency.

Embodiment 5 to 7 and comparative Embodiment 5 to 7

[0271] The kneaded materials having the components shown in Table 1 were respectively kneaded under the kneading conditions shown in Table 1. These materials were separately processed in the same manner as in Example 1 to obtain a pigment composition. The organic pigment used in Example 5 and Comparative Example 5 was CIPigment Yellow 138 (Paliotol Yellow K0691HD, provided by BASF), and the organic pigment used in Example 6 and Comparative Example 6 was CIPigment Red 177 (Chromophthal Red A2B , Provided by Ciba Specialty Chemicals Co.), the organic pigment used in Example 7 and Comparative Example 7 is CIPigment Violet 23 (Sumiton Fast Violet RL Base, provided by Sumitomo Chemical Co., Ltd).

[0272] In Examples 5 to 7, the ΔL of the coating product prepared from the pigment composition obtained with a small amount of electric power consumption * The value is larger than that in Comparative Examples 5 to 7, and the transparency in Examples 5 to 7 is very good.

[0273] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com