Pneumatic tool with improved structure

An air tool and air chamber technology, applied in the field of air tools with improved structure, can solve problems such as unfavorable production and increased difficulty in the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with accompanying drawings, which are for illustration purposes only, and are not limited by this structure in patent applications.

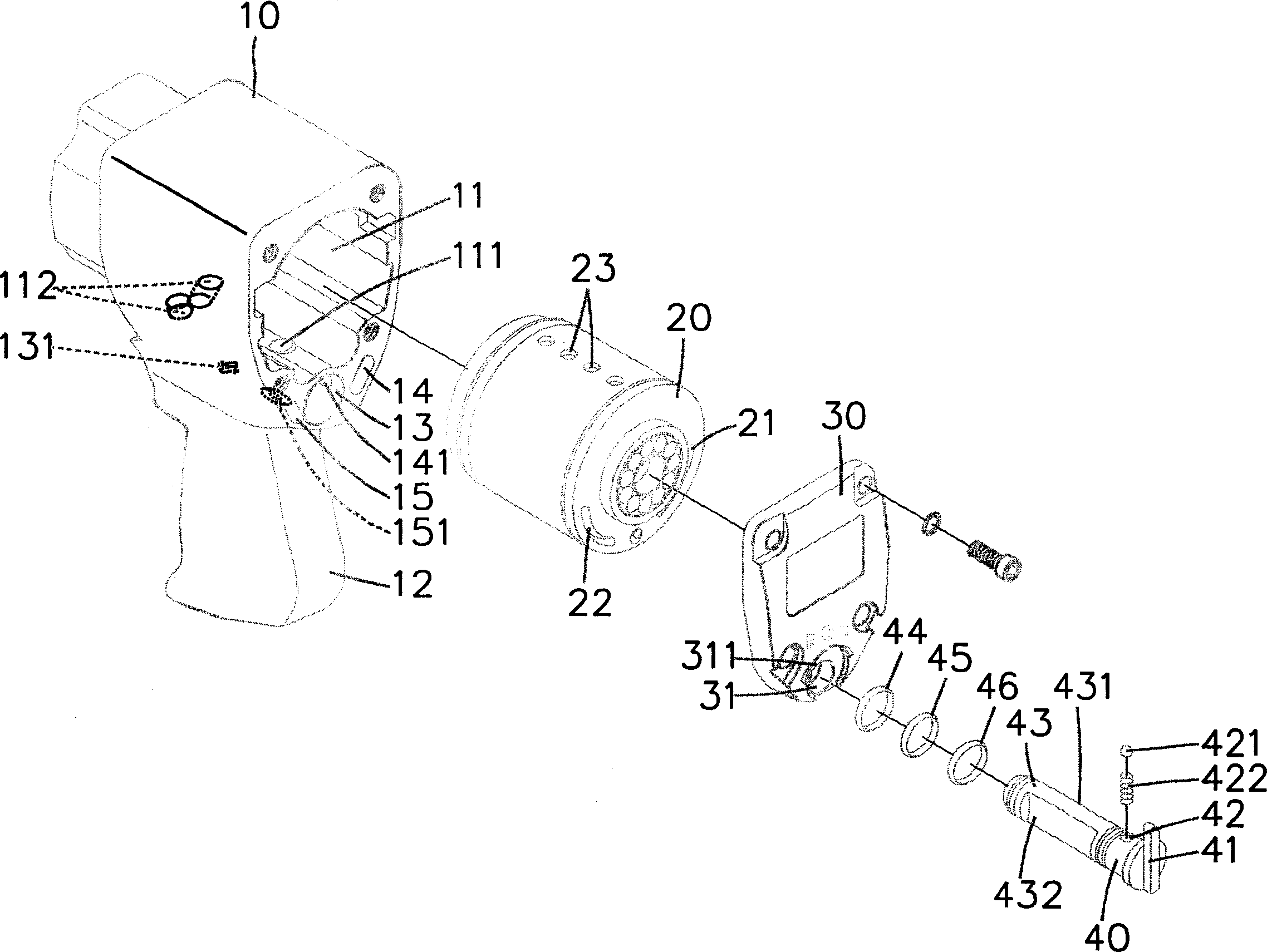

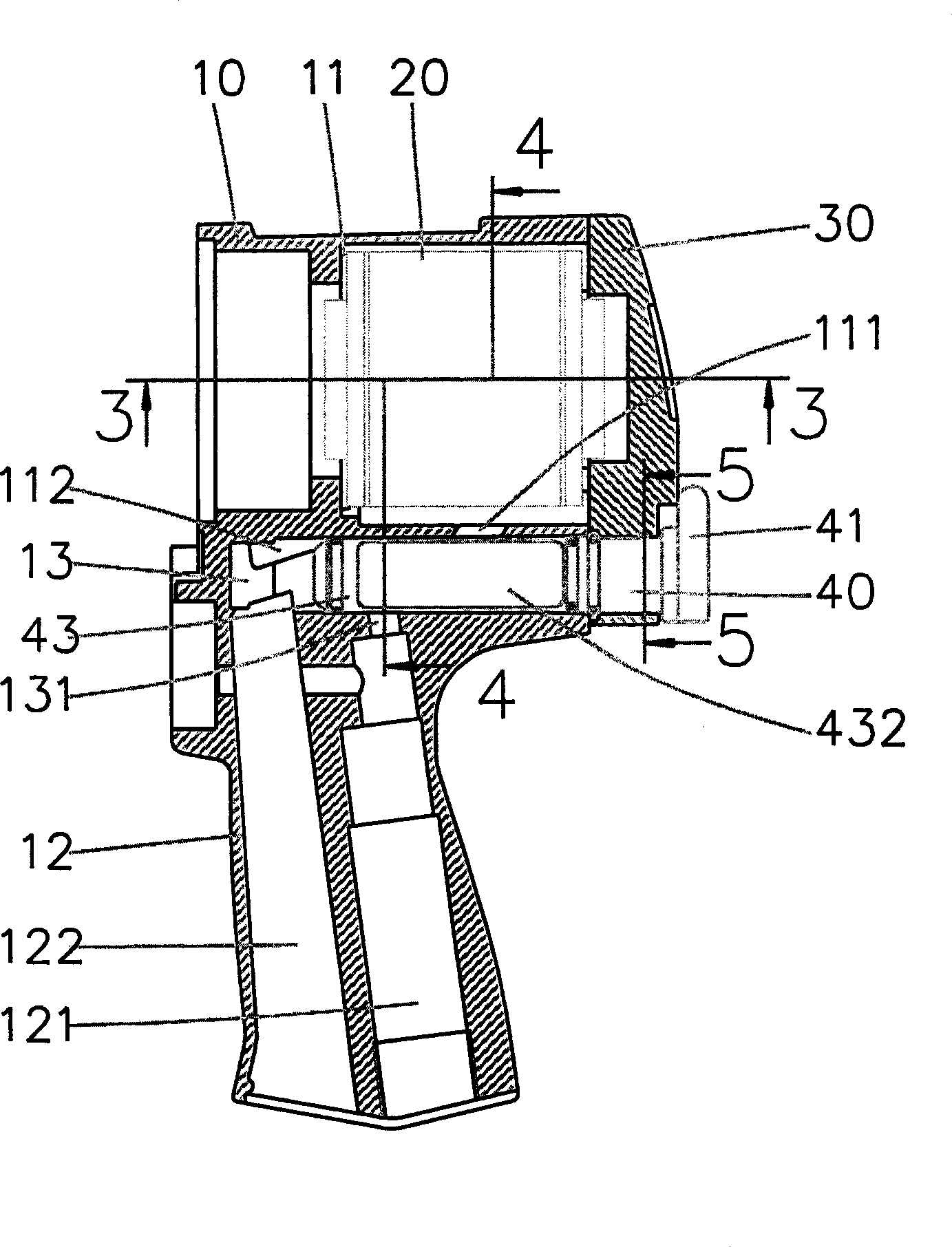

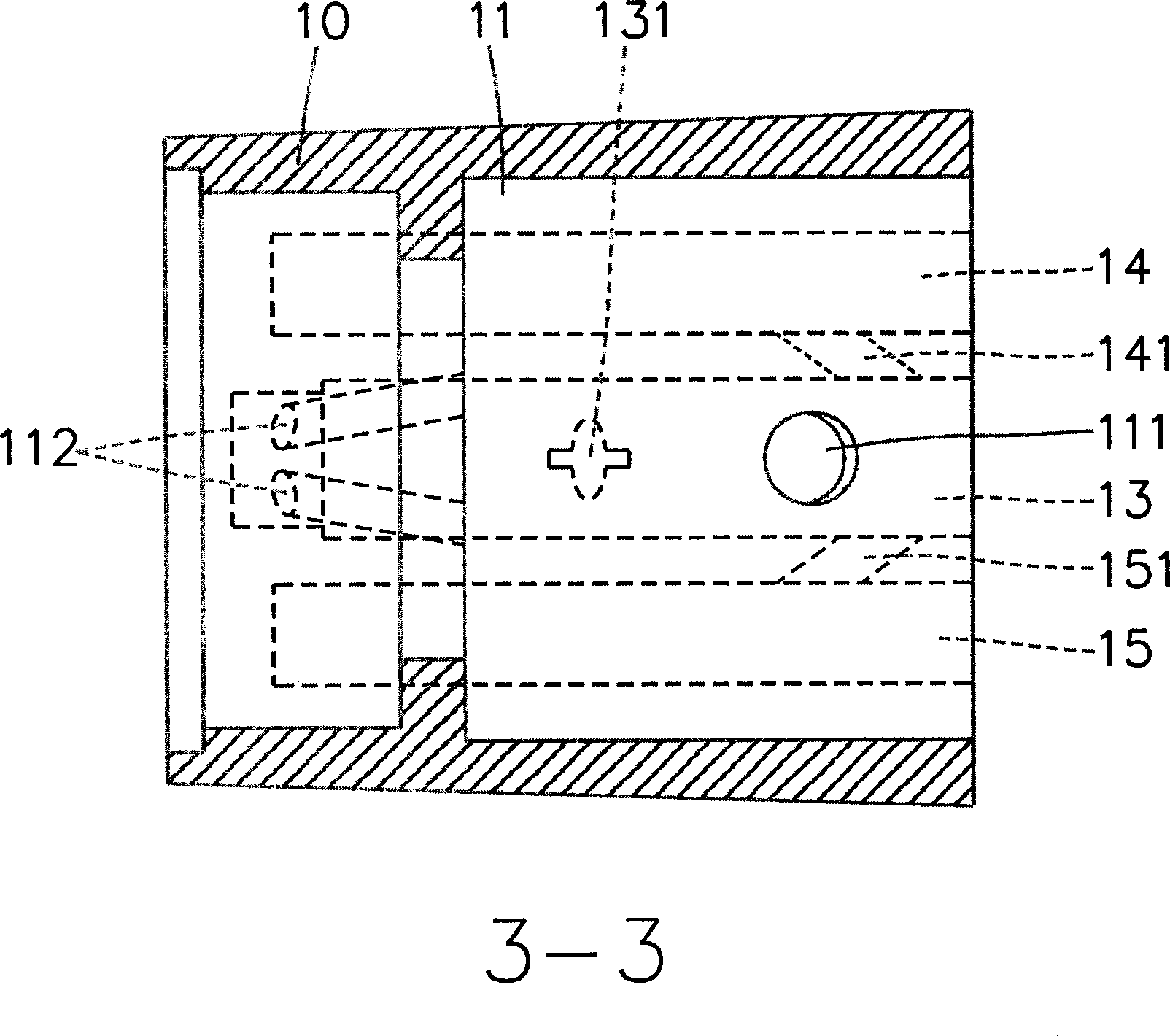

[0047] refer to Figure 1 to Figure 3 , the present invention includes a body 10, a cylinder block 20, a cover 30 and a control member 40; the body 10 is provided with a cross-shaped flow control hole 13, the cylinder block 20 is located in the body 10, the seal The cover 30 is used to close the cylinder group 20, and the control member 40 can cooperate with the flow control hole 13 to adjust the rotation speed and steering direction of the cylinder group 20, and the two sides of the control member 40 are provided with an axially extending Moreover, the non-intersecting forward rotation guide groove 431 and reverse rotation guide groove 432 can effectively simplify the manufacturing process and further r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com