Corona and moisture film purification method and device for oil smoke

A technology of oil fume purification and water film, applied in the direction of electrostatic separation, electrode cleaning, external electrostatic separator, etc., can solve the problems of dust collection equipment failure, dust collection efficiency reduction, low operating cost, etc., to increase operation and maintenance costs , Increase the width of the electric field, the effect of high dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

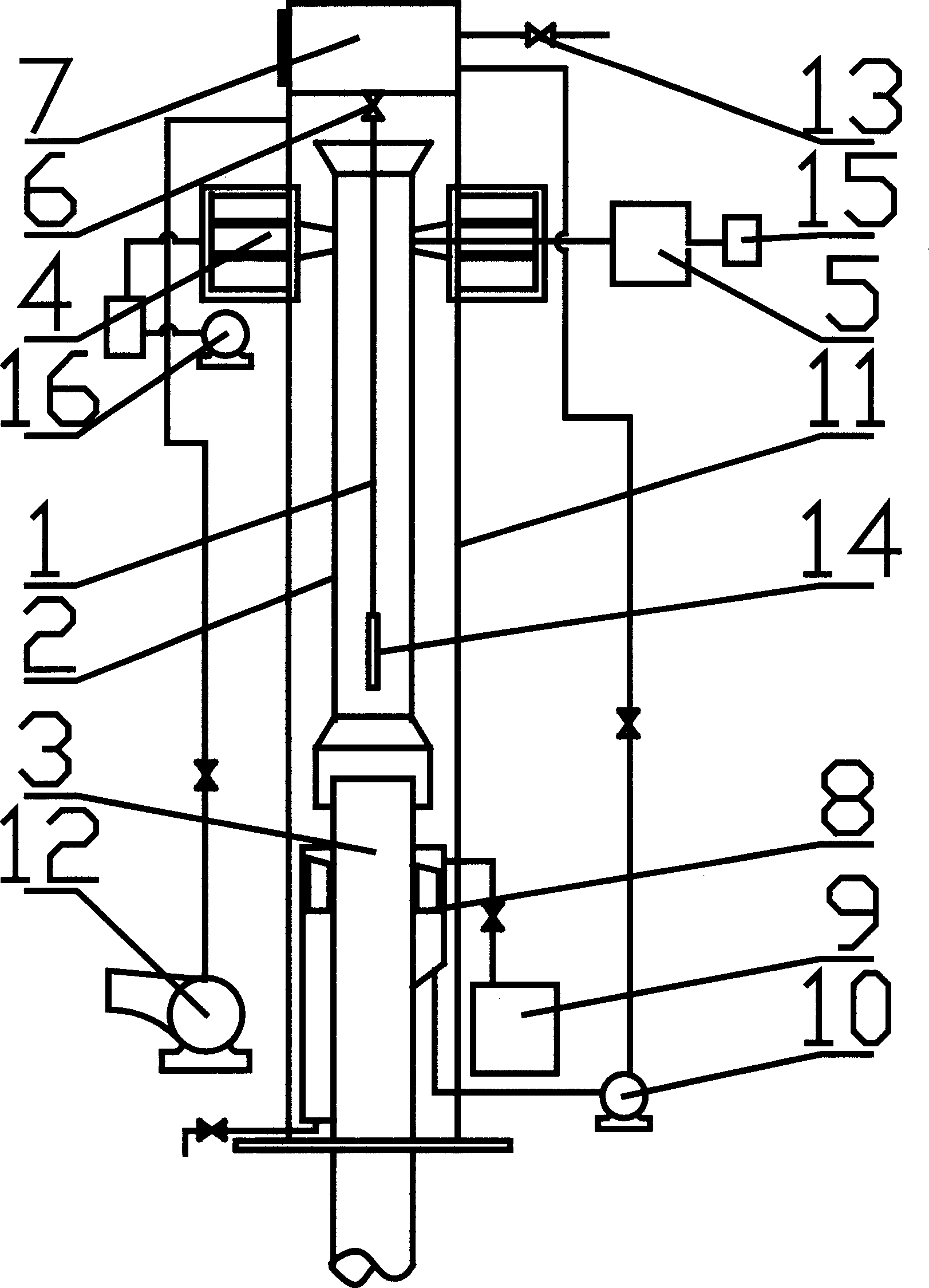

[0012] Embodiments of the present invention: the present invention can adopt the existing dust collection plate tube 2, the middle of the dust collection plate tube 2 is inserted into the corona pole wire 1, and the bottom of the corona pole wire 1 is provided with a plumb weight 14 for keeping vertical , the corona pole wire 1 and the dust collector plate tube 2 are respectively connected to the negative pole and the positive pole of the power supply 5, the power supply 5 is connected to the control device 15, and the water tank 7 with the adjustment switch 6 is installed above the corona pole wire 1, which can be adjusted according to the dust collection Adjust the amount of water flowing to the corona pole wire 1, and install a new water replenishment valve 13 on the water tank 7; the dust collector plate tube 2 is fixed by the insulator 4 on both sides. The insulator 4 is supported by the hydraulic pump 16, and the dust collection pipe 3 is connected under the dust collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com