Hot work tool steel and mold member excellent in resistance to melting

A lossy, melting-resistant technology, applied in the direction of manufacturing tools, metal processing equipment, metal material coating technology, etc., can solve the problems of base metal melting loss and other problems, achieve the reduction of repair costs, reduce costs, and extend the repair cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

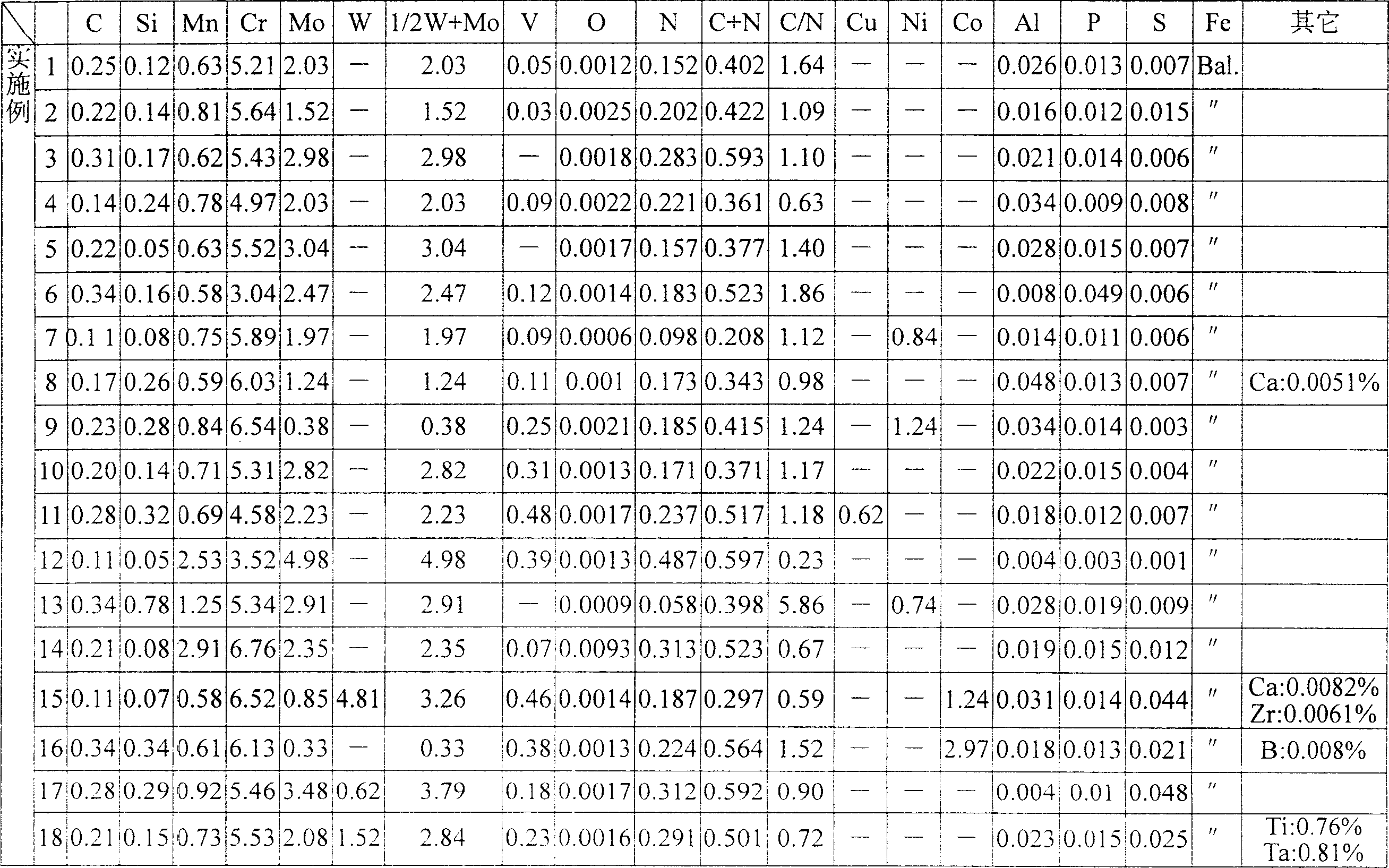

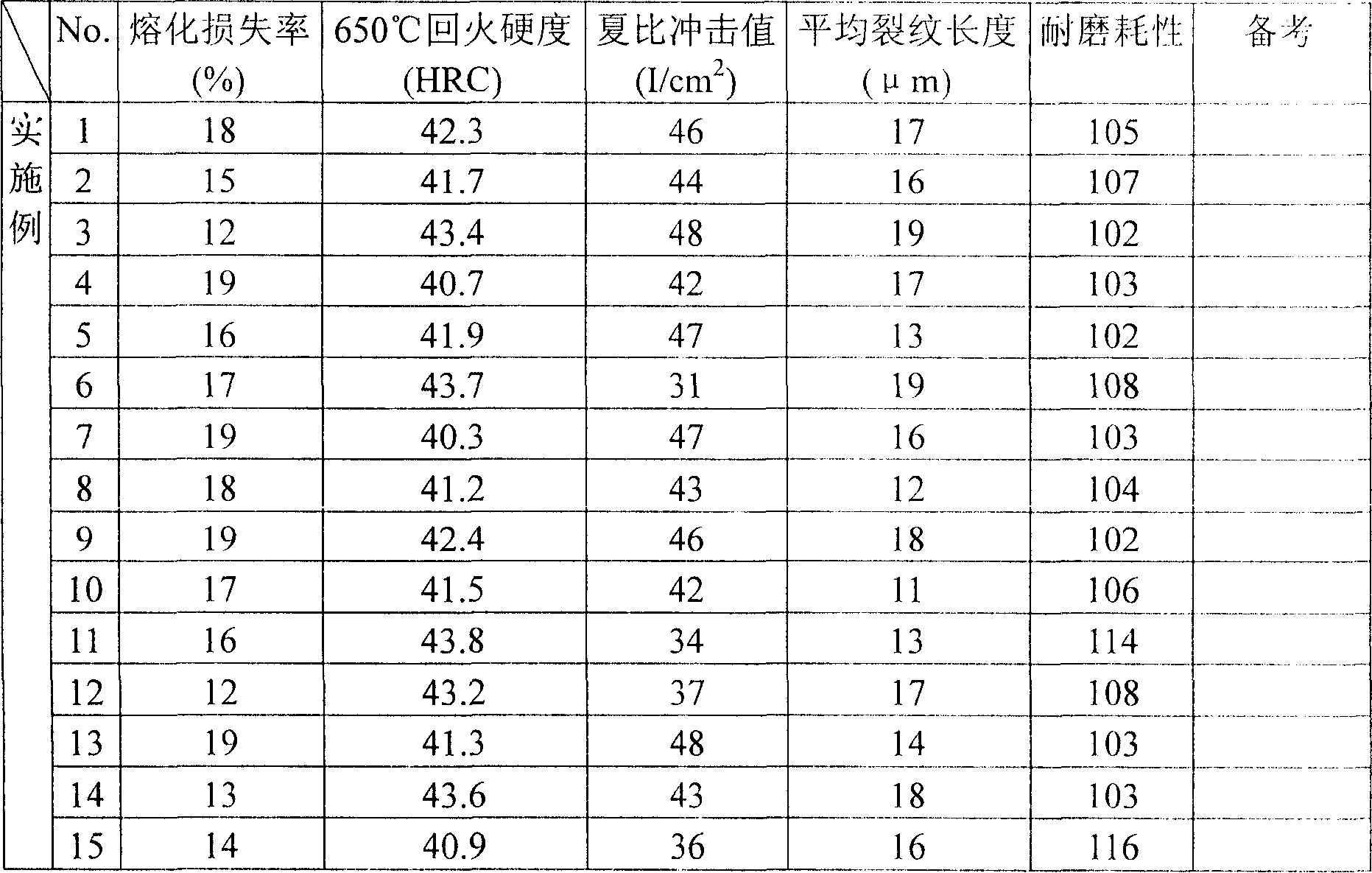

[0120] In order to increase the nitrogen concentration in the steel ingot, 50 kg of steel with the composition shown in Table 1 was melted and cast in a pressurized melting furnace capable of pressurizing the entire melting and casting device up to 10 atmospheres. However, the conventional steels in Table 1 were melted and cast in a vacuum melting furnace.

[0121] Table 1 chemical composition

[0122]

[0123] 19

0.33

0.24

0.58

6.92

1.98

-

1.98

0.14

0.0023

0.143

0.473

2.31

-

-

4.98

0.021

0.012

0.043

″

Se: 0.0065%

Te: 0.0041%

20

0.26

0.19

0.61

6.24

2.76

-

2.76

0.35

0.0014

0.162

0.422

1.60

-

-

0.033

0.013

0.008

″

M...

Embodiment 2

[0155] Regarding the steel (example and conventional steel) with the composition shown in Table 4, a 50 kg ingot was melted in the same pressurized melting furnace (example) and vacuum induction furnace (conventional steel) as in Example 1, and cast into a circle of Φ20 mm. material, and then tempered at 870°C.

[0156] differentiate

[0157] Next, after the examples and conventional steels were cut into three lengths of 200 mm each, they were roughly machined to Φ15 mm×200 mm by turning, and then tempered at 1030°C×1hr, and then tempered at 580-590°C×8hr. Temper twice to adjust the hardness to HRC38, 45, 52 respectively.

[0158] Then, these are finished into the shape of cast-drawn pins, and then surface treatment for surface modification is performed.

[0159] Here, as for the surface treatment, in the examples and conventional steels, the HRC38 material was subjected to gas nitrocarburization under the condition of 525°C×2.5hr, and the HRC52 material was formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com