Heat shrinking positioning method and heat shrinking positioning plate for super-thin wire conduit

A technology of ultra-thin wires and positioning methods, applied in the direction of cable joints, cable installation devices, electrical components, etc., can solve the problems of easy errors in manual operation, and achieve the effect of simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

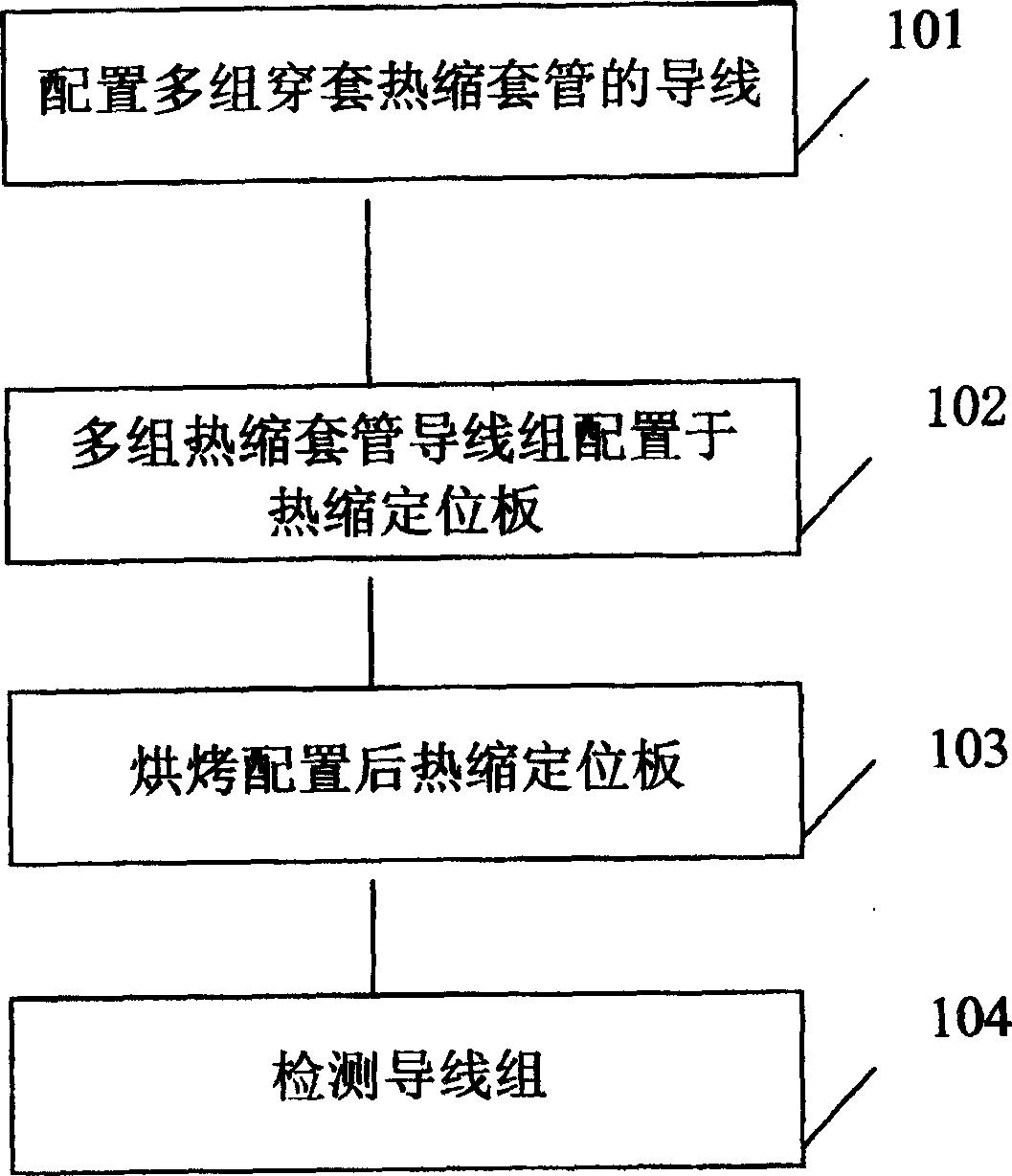

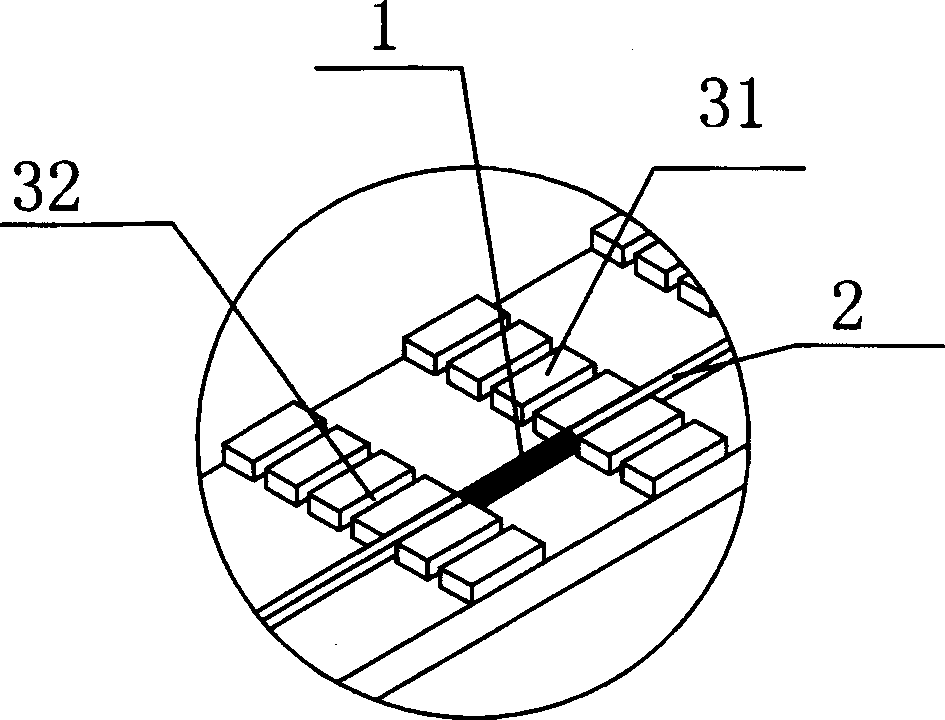

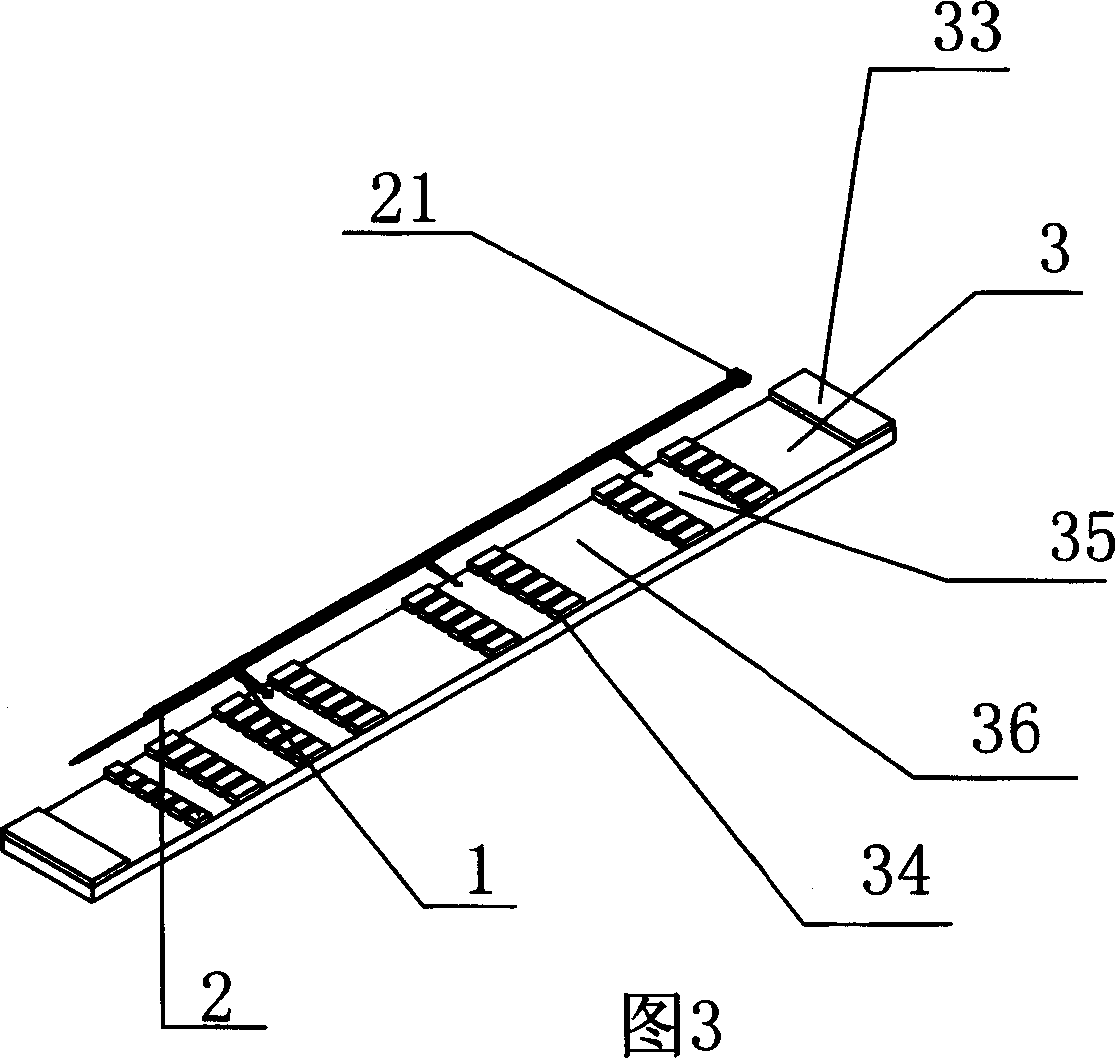

[0023] control figure 1 To 3 below for further description:

[0024] A heat-shrinkable positioning method for ultra-fine wire sleeves, which is used for heat-shrinking and positioning multiple sets of ultra-fine wire sleeves at the same time, comprising the following steps in sequence:

[0025] 1). Put multiple heat-shrinkable sleeves 1 through the wire group 2 formed by one or more wires;

[0026] 2). Place the wire group in the transverse limit groove 32 arranged at intervals by a plurality of casing positioning blocks 31 on the heat-shrinkable positioning plate 3, and connect the flush end 21 of the wire group to the heat-shrinkable positioning plate The stop portion 33 at one end is aligned;

[0027] 3). A plurality of heat-shrinkable sleeves on the wire group are respectively limited in a plurality of longitudinal limiting grooves 35 arranged at intervals by a plurality of block rows 34 on the heat-shrinkable positioning plate, so as to facilitate hot air baking;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com