Ceramic brick feeding device and its use method

A technology for distributing devices and ceramic tiles, which is applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of long displacement distance of grid 1, large displacement deformation of powder material, large pattern deformation, etc., and achieve small relative displacement deformation and accurate distribution , the effect of small displacement deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

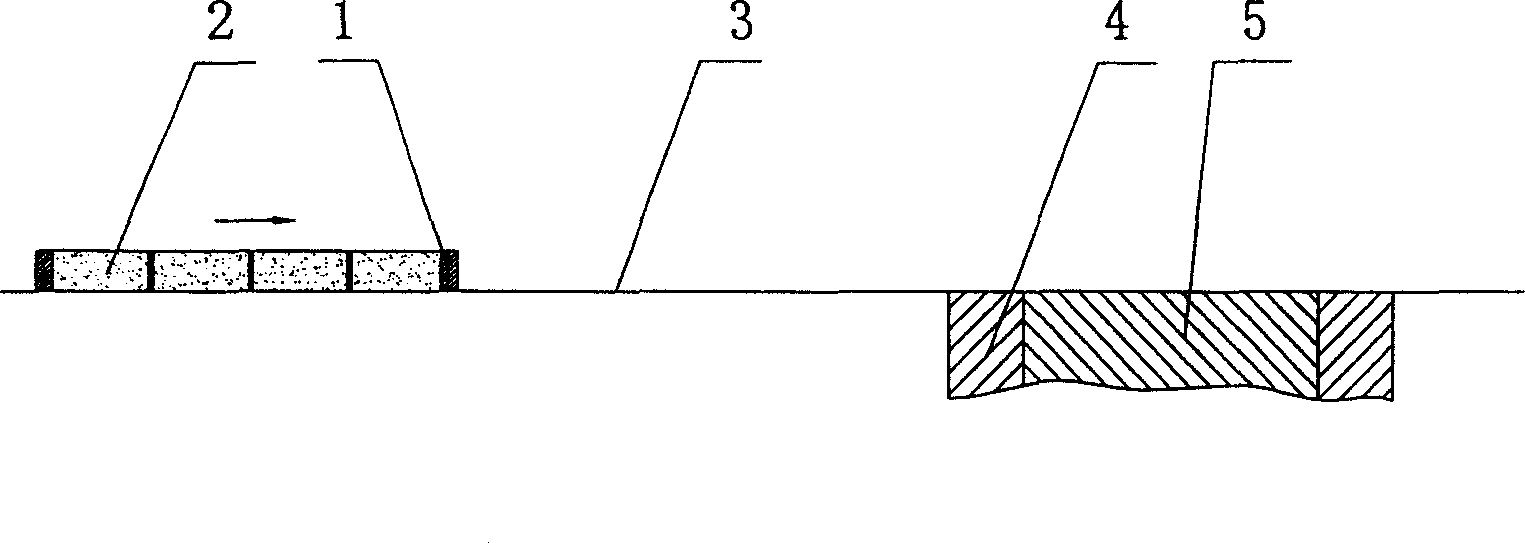

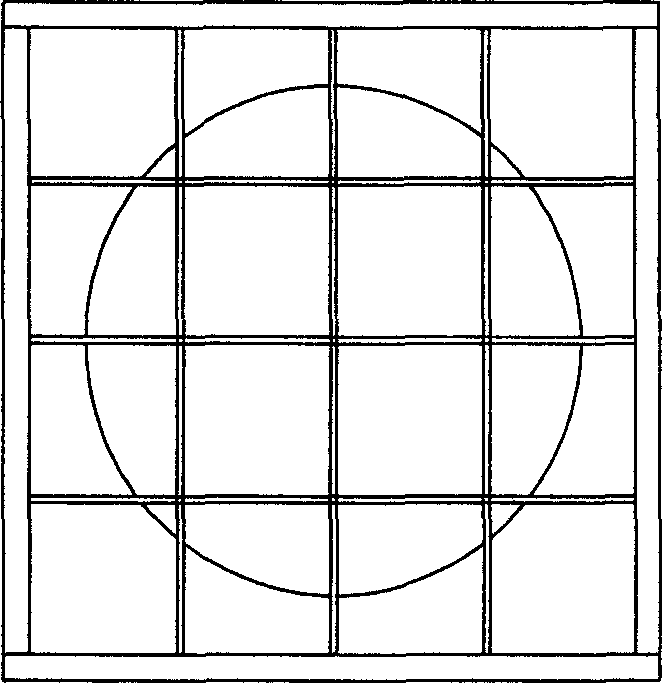

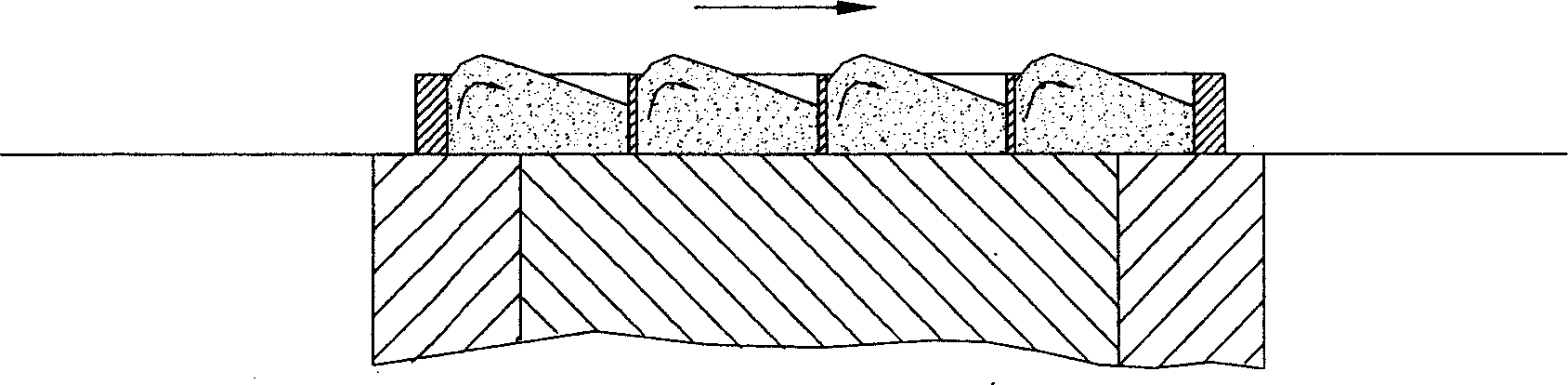

[0041] image 3 It is a structural schematic diagram of an embodiment of the single-layer movable floor distribution device of the present invention. The device of the present invention comprises a grid 1, and a movable bottom plate 8 which can make the ceramic brick powder 2 in the grid fall by moving is arranged under the grid 1. Such as image 3 As shown, since the movable bottom plate 8 is added under the grid 1, the bottom surface of the powder material 2 is directly in contact with the movable bottom plate 8. When the device of the present invention is transferred to the mold frame 4, since the movable bottom plate 8 has no displacement relative to the powder material , so there is no powder displacement deformation, only when the device of the present invention is moved to the plane of the mold core 5, the movable bottom plate 8 has a relative displacement process with respect to the powder 2, and the displacement distance is relatively short. Compared with the prior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com