Display device, manufacturing method thereof, organic light emitting device, and manufacturing method thereof

一种有机发光装置、显示装置的技术,应用在有机发光装置及其制造,表面发光型显示装置领域,能够解决降低发光效率、差色泽复现性显示装置、电能消耗和器件寿命大负担等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0059] First, refer to figure 1 A display device according to a first embodiment of the present invention will be described. figure 1 is a cross-sectional view of a model illustrating a configuration example of a display device according to this embodiment. The display device 1 in the illustration is a full-color display device in which each organic EL device 3B, 3G, and 3R is arranged and formed on a substrate 2, each of blue (B), green (G), and red (R) Colors emanate from it. The display device 1 displays images using the organic EL phenomenon. Each of the organic EL devices 3B, 3G, and 3R has a configuration in which a lower electrode 4 , a transparent conductive layer 5 , a functional layer 6 , and an upper electrode 7 are layered from the substrate 2 side. The display device is configured as a top emission type display device in which emitted light h emitted in the functional layer 6 is extracted from the side of the upper electrode 7 opposite to the substrate 2 . The...

no. 2 example

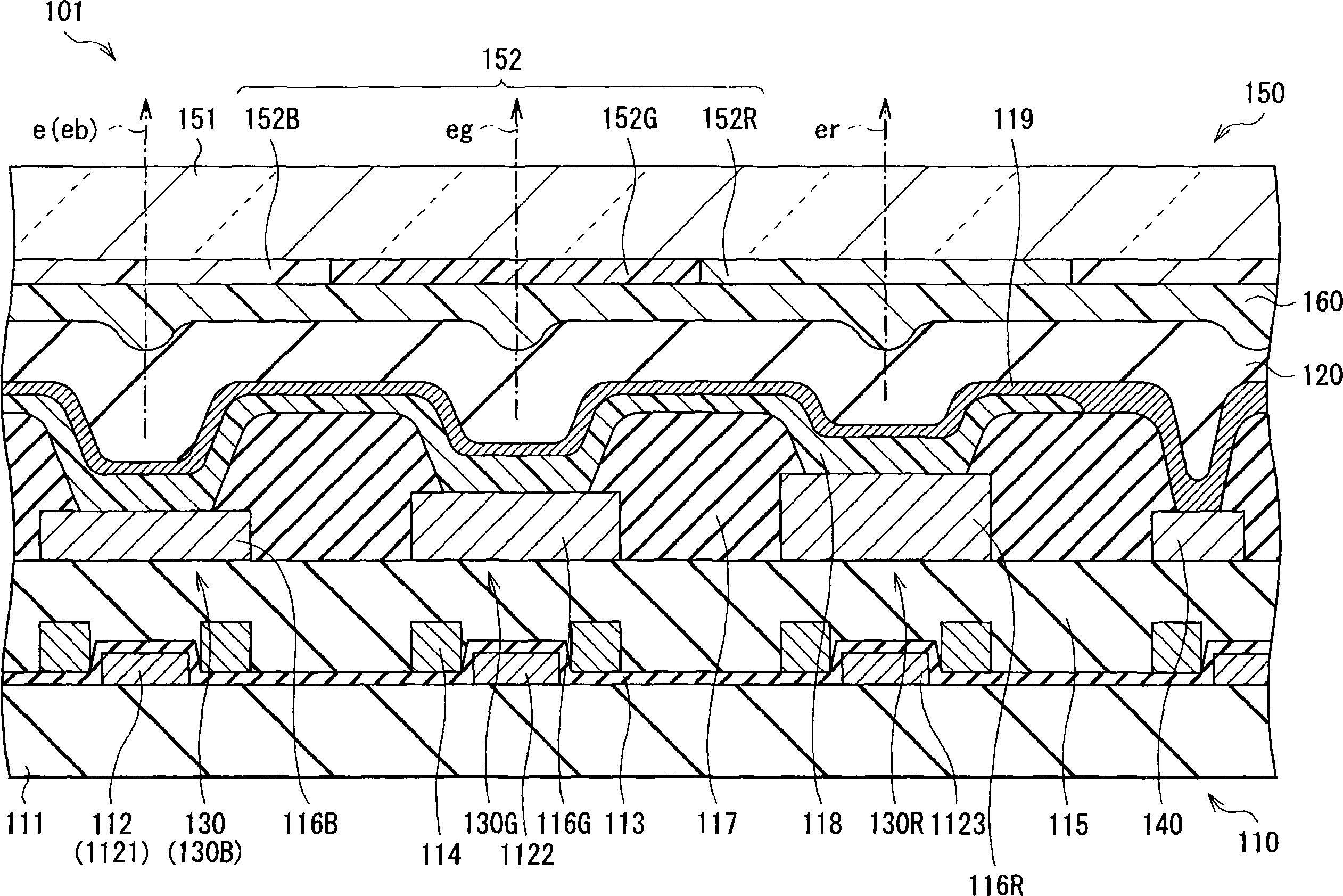

[0102] Next, we will refer to image 3 A display device according to a second embodiment of the present invention will be described. image 3 A cross-sectional configuration of the display device 101 is shown.

[0103] The display device 101 displays images using the organic EL phenomenon. For example, if image 3 As shown, in the case where the organic light-emitting device is equipped with an organic EL device 130 and a driving device (TFT: Thin Film Transistor) 112 for driving the organic EL device 130, the driving panel 110 and the sealing panel 150 are relatively arranged, and the intermediate The adhesive layer 160 bonds the driving panel 110 and the sealing panel 150 together, thereby sandwiching the organic EL device 130 between the driving panel 110 and the sealing panel 150 . For example, the display device 101 has a top emission type structure for emitting light e generated in the organic EL device 130 upward, that is, toward the outside of the sealing panel 150 ...

no. 3 example

[0175] Next, a third embodiment of the present invention will be described.

[0176] The display device according to this embodiment has a structure similar to that of the display 101 described in the second embodiment above ( Figure 3 to Figure 5 ) structure, except that the formation steps of the lower electrode layers 116R, 116G, and 116B are different, the display device according to this embodiment can be manufactured using manufacturing steps similar to those of the display 101 . In this embodiment, specifically, for example, in order to accurately form the barrier layers 1163R, 1163G, and 1163B of the lower electrode layers 116R, 116G, and 116B, the barrier layer portion 11631 is preferably made of tin oxide (SnO 2 ) or chromium oxide (CrO), the barrier layer portion 11632 is composed of ITO, and the barrier layer portion 11633 is composed of IZO.

[0177] Figure 12 to Figure 19 The role of is to explain the manufacturing steps of the lower electrode layers 116R, 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com