Push belt

A technology of pulleys and components, which is applied in the belt pressure field of continuously variable transmissions, can solve problems such as consumption and torque reduction, and achieve the effects of torque transmission, deflection prevention, and high-efficiency torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the figures, the same reference numerals correspond to the same or at least comparable technical features.

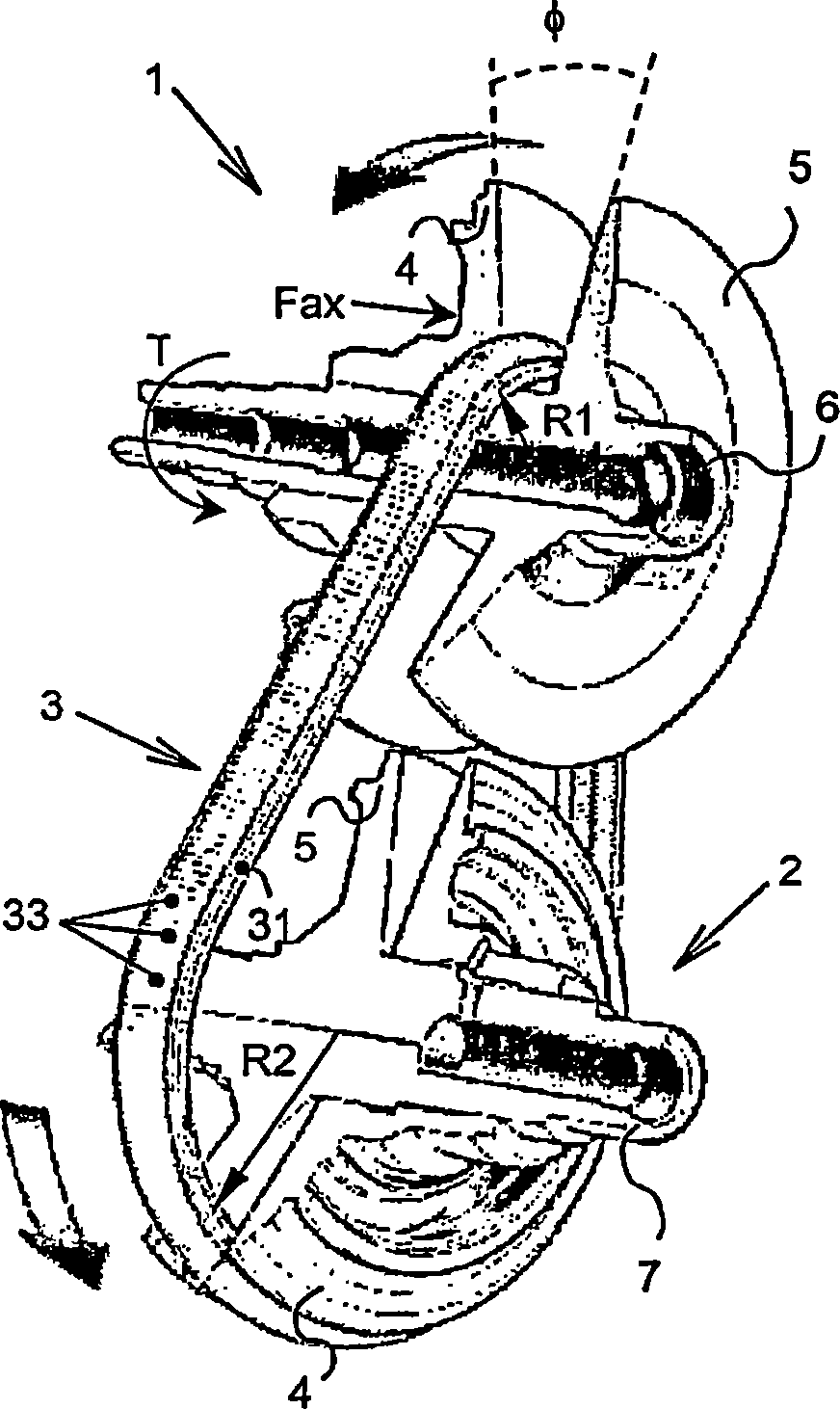

[0020] figure 1 The central part of a known continuously variable transmission is shown, which is usually applied on the drive train of a family car, between the engine and the drive wheels. The variator comprises two pulleys 1, 2 provided respectively with two pulley sheaves 4, 5 between which a metal pressure belt 3 is arranged for transferring the rotational movement from one pulley 1 and the associated The torque is transmitted to the other pulley 2. The pulley sheaves 4 , 5 are substantially conically shaped and at least one pulley sheave 4 is accommodated in the transmission in such a manner that it is axially displaceable along a carried corresponding pulley shaft 6 , 7 . The variator usually also comprises actuating means, which exert an axially directed clamping force Fax on said at least one pulley 4, directed towards the corresponding other pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com