Work transfer device for press machines

一种输送装置、工件的技术,应用在进给装置、定位装置、储存装置等方向,能够解决机器人障碍、作业复杂、缩短等问题,达到高精度的定位、高速输送定位、设置空间小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

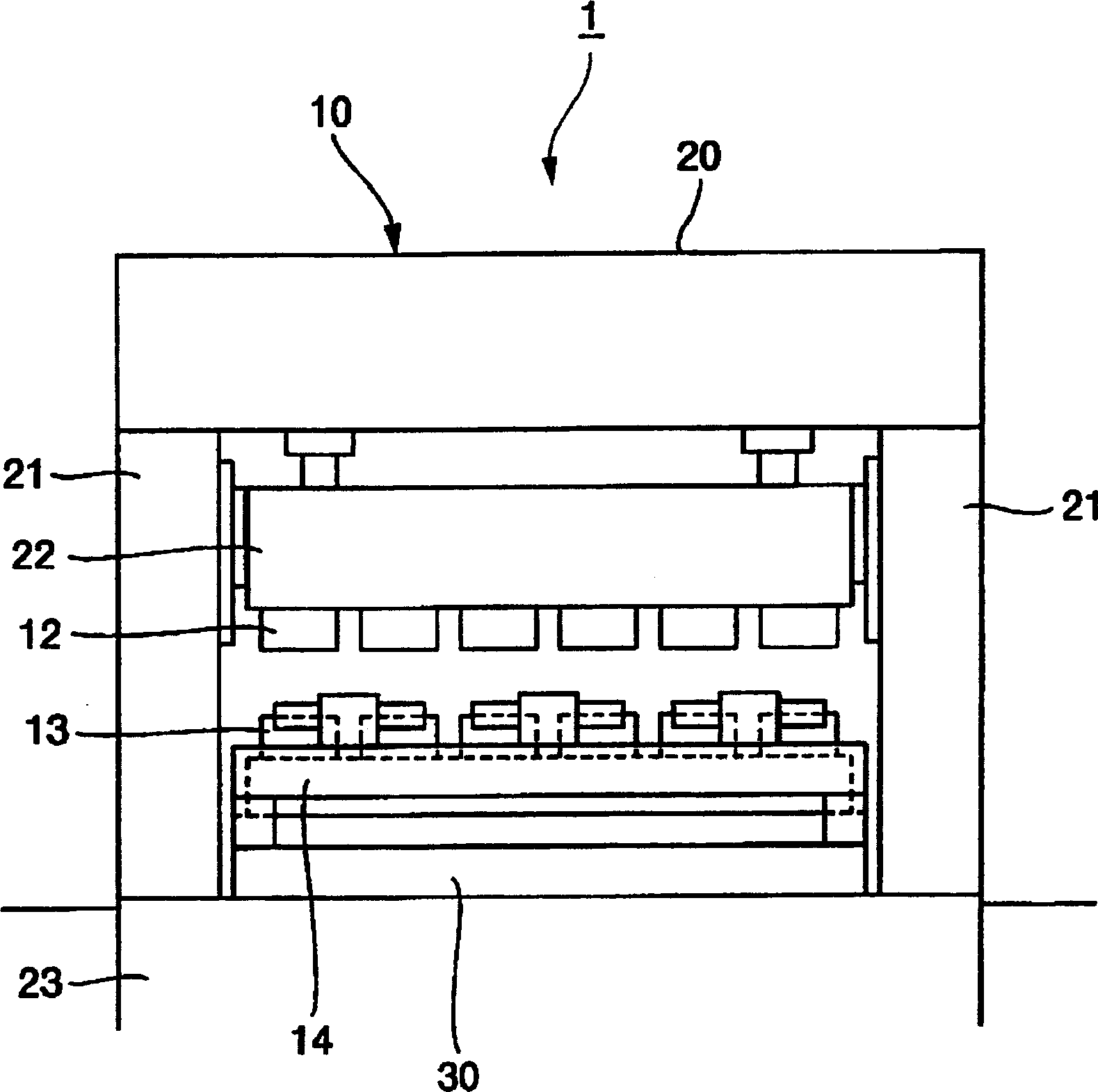

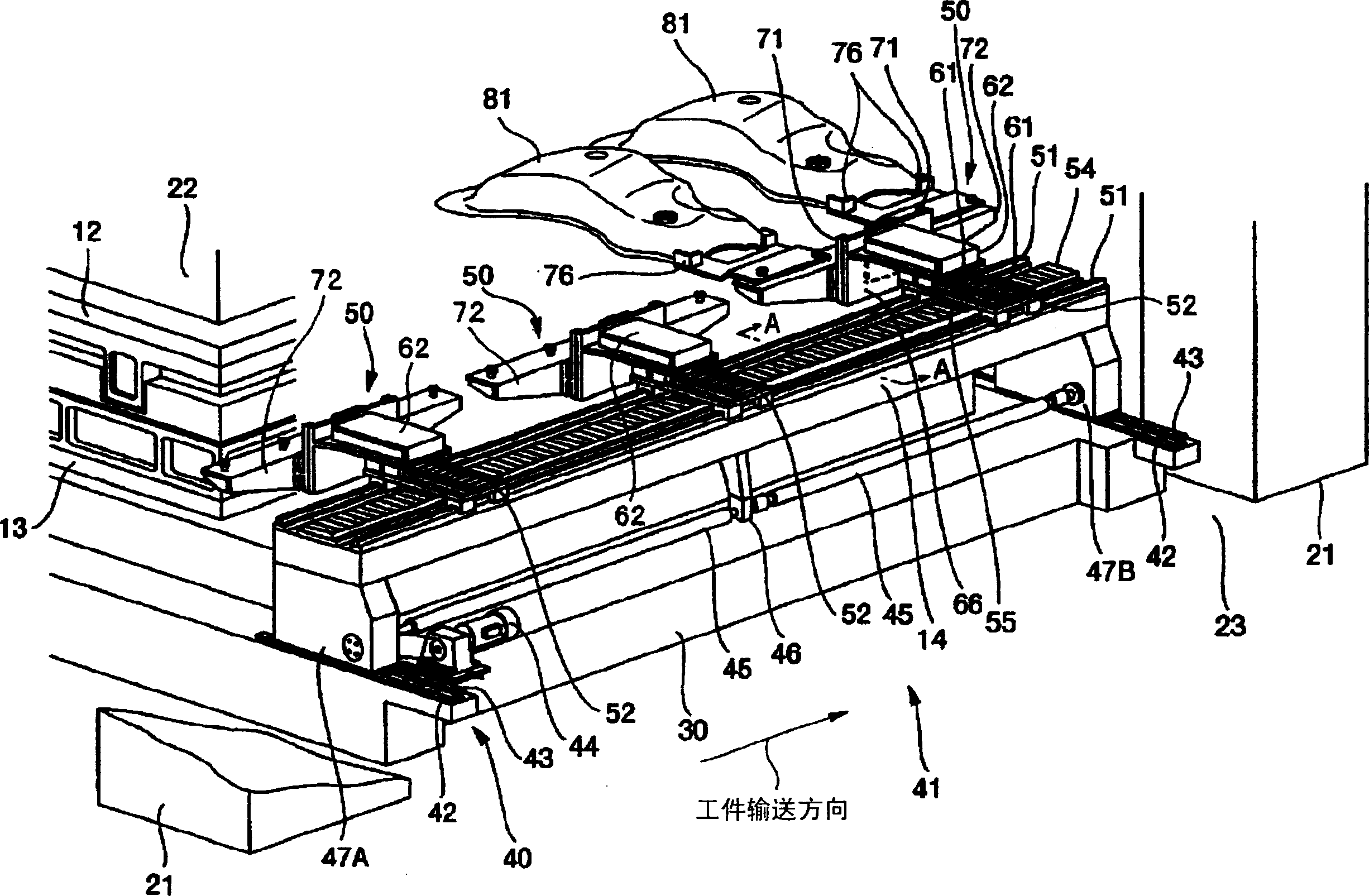

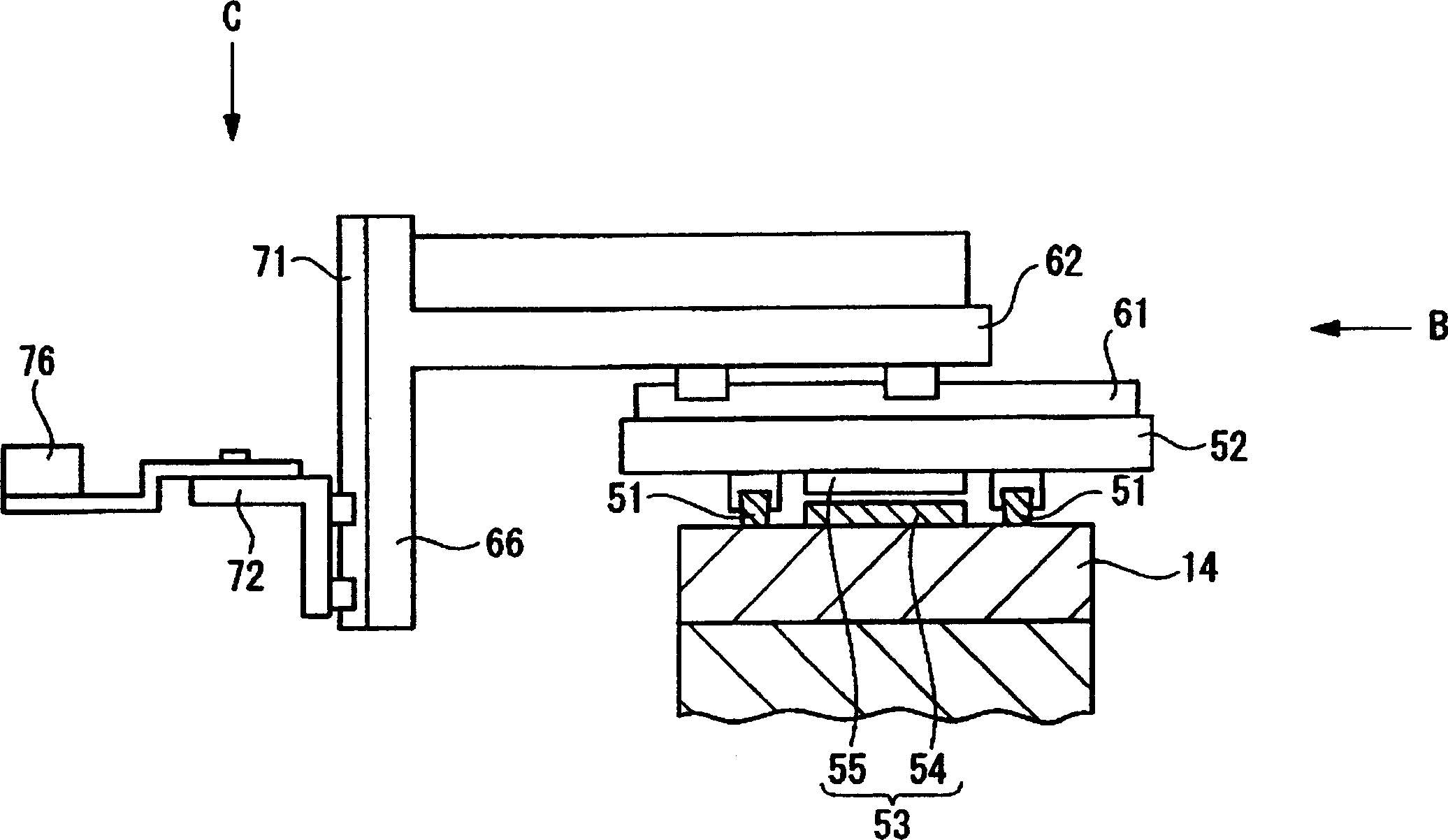

[0092] figure 1 It is a front view of the conveying and feeding device (press machine) 1 provided with the workpiece conveying device according to the first embodiment of the present invention. figure 2 It is a perspective view of the conveying and feeding device 41 which is a workpiece conveying device. Figure 3 to Figure 5 An enlarged view of a part of the transport feeding device 41 is shown.

[0093] First, if figure 1 As shown, four pillar-shaped struts 21 are erected on the machine base 23 located at the bottom of the press frame 10 of the conveying press 1 , and a beam 20 is arranged on the upper surface of the struts 21 . A sliding drive device is built in the crossbeam 20 to lift and drive the slide plate 22 below the crossbeam 20 . Furthermore, the upper die 12 is attached to the lower surface of the slide plate 22 . An upper mold 13 is arranged on the upper surface of the movable backing plate 30 opposite to the slide plate 22 , and the workpiece is press-fo...

no. 2 approach

[0121] Next, use Figure 12 The conveying and feeding device 41A of the second embodiment will be described. Figure 12 It is a perspective view of the conveying and feeding device 41A which is a workpiece conveying device. The same reference numerals are attached to the same components as those described in the first embodiment, and description thereof will be omitted.

[0122] A lower mold 13 is provided on the upper surface of the movable backing plate 30A opposite to the slide plate 22 (refer to figure 2 ), using the upper mold 12 (refer to figure 2 ) and the linkage of the lower mold 13 to press-form the workpiece. A pair of left and right rods 14 , 14 extend parallel to the workpiece conveying direction with the upper die 12 and the lower die 13 interposed therebetween.

[0123] Figure 12 In the illustrated case only one side of the pair of rods 14A, 14A is shown. Such as Figure 12 As shown, on the movable backing plate 30A that can move automatically, in Fi...

no. 3 approach

[0136] Next, use Figure 13 The conveying and feeding device 41B of the third embodiment will be described. Figure 13 It is a perspective view of the conveying and feeding device 41B which is a workpiece conveying device. The same reference numerals are attached to the same components as those described in the first embodiment, and description thereof will be omitted.

[0137] In the third embodiment, in the first embodiment, adjacent feed pallets 52 are connected by a connection mechanism 56 . Thereby, the several feed pallet 52 is arrange|positioned so that the adjacent feed pallet 52 may respectively have predetermined intervals. By disposing in this way, all the feed pallets 52 supported by one rod 14 operate in conjunction with each other, so it is not necessary to provide a feed drive mechanism for each of the feed pallets 52 . exist Figure 13 Among them, only one feed pallet 52 on the upstream side is provided with a linear motor 53B which is a feed drive mechanism....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com