Electromagnetic permanent magnet electric machine

A permanent magnet motor and electromagnetic technology, applied in the field of electric motors, can solve the problems of difficult excitation adjustment of permanent magnet motors, small air gap magnetic density, low efficiency of electric excitation motors, etc., to prevent irreversible demagnetization, excellent magnetic properties, and saving raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A detailed explanation and examples of the invention are provided below:

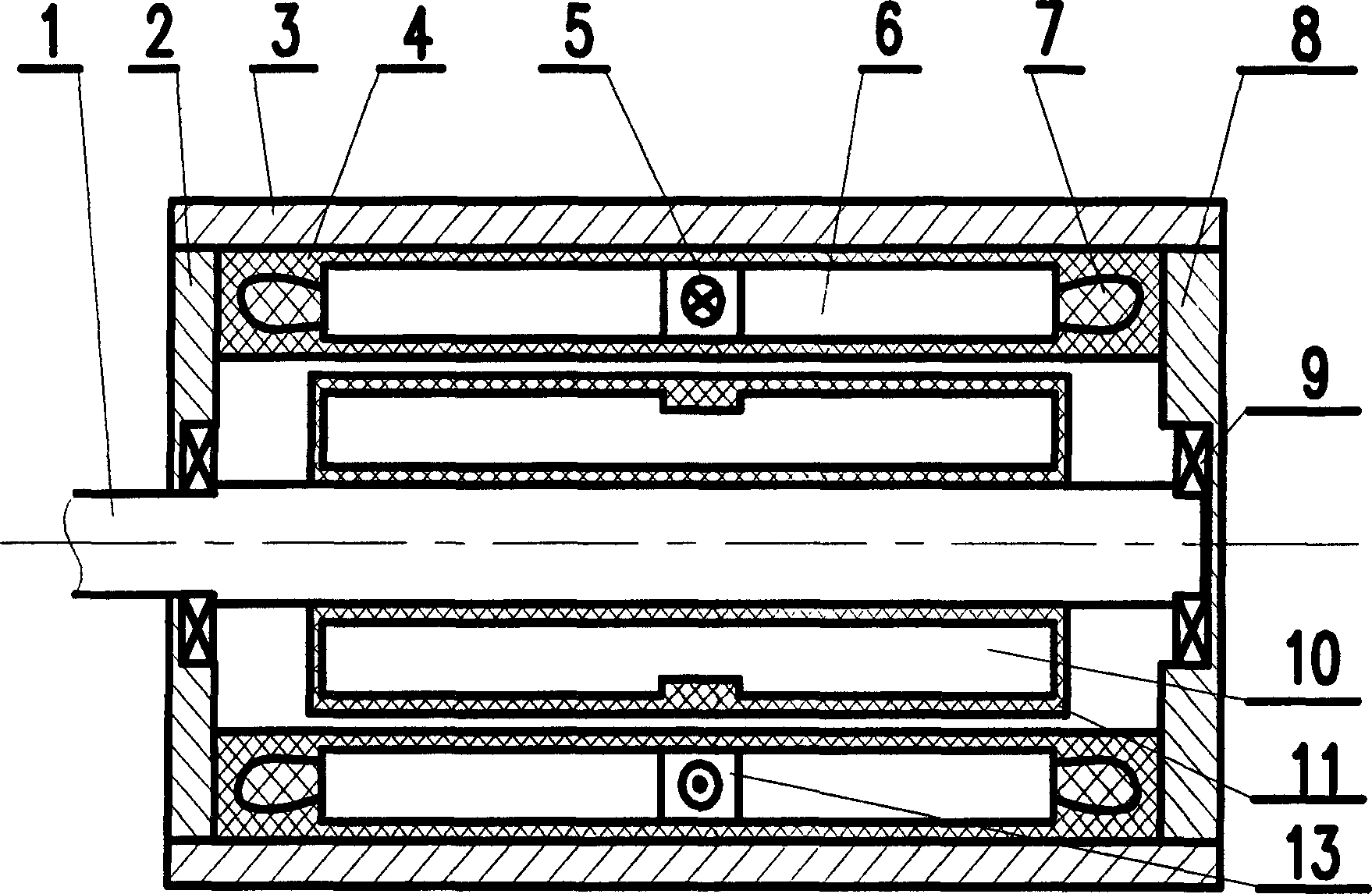

[0030] Basic structure of the present invention sees figure 1 , wherein the stator and the rotor are sealed with polymer materials, such as polymer resin materials, respectively.

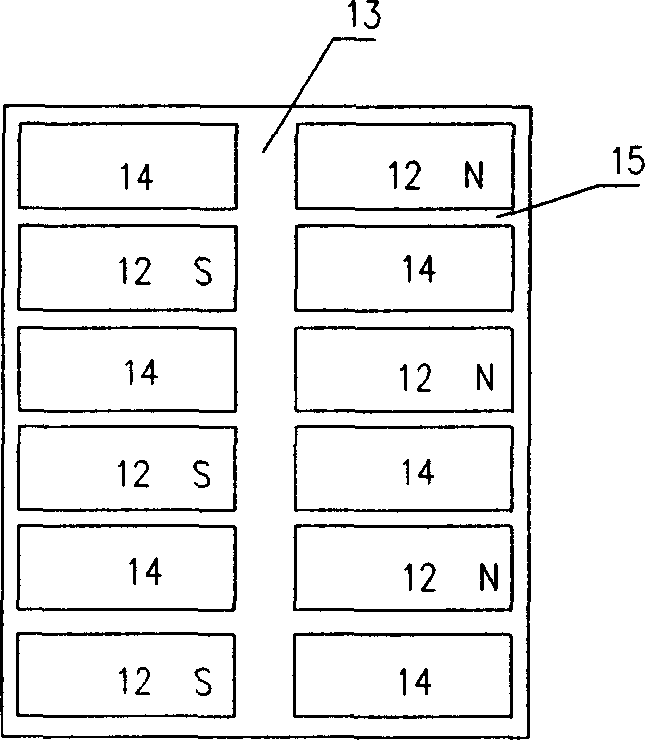

[0031] The arrangement of the permanent magnet and the magnetic adjustment pole on the rotor of the present invention is as follows: image 3 and shown in Figure 4. Depend on image 3As can be seen from FIG. 4 , an annular groove 13 is arranged on the rotor core 16 , and this annular groove is arranged at half of the rotor width. The excitation coil 7 is arranged on the stator corresponding to the annular groove 13 . Axial slots along the axial direction are arranged on both sides of the annular slot on the rotor, and these axial slots are arranged at staggered intervals along both sides of the annular slot. Between each axial slot is a magnetic adjustment pole 14 made of soft iron of the rotor core. The permanen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com