Device and method for continuously producing fluorescent tubes

A technology for fluorescent tubes and production equipment, applied in the manufacture of discharge tubes/lamps, machines with sequentially arranged working positions, electrical components, etc., can solve the problems of continuous production equipment for fluorescent tubes, unresolved problems of technical connection, manpower and Energy waste and other issues, to achieve the effect of increasing per capita productivity, reducing personnel, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

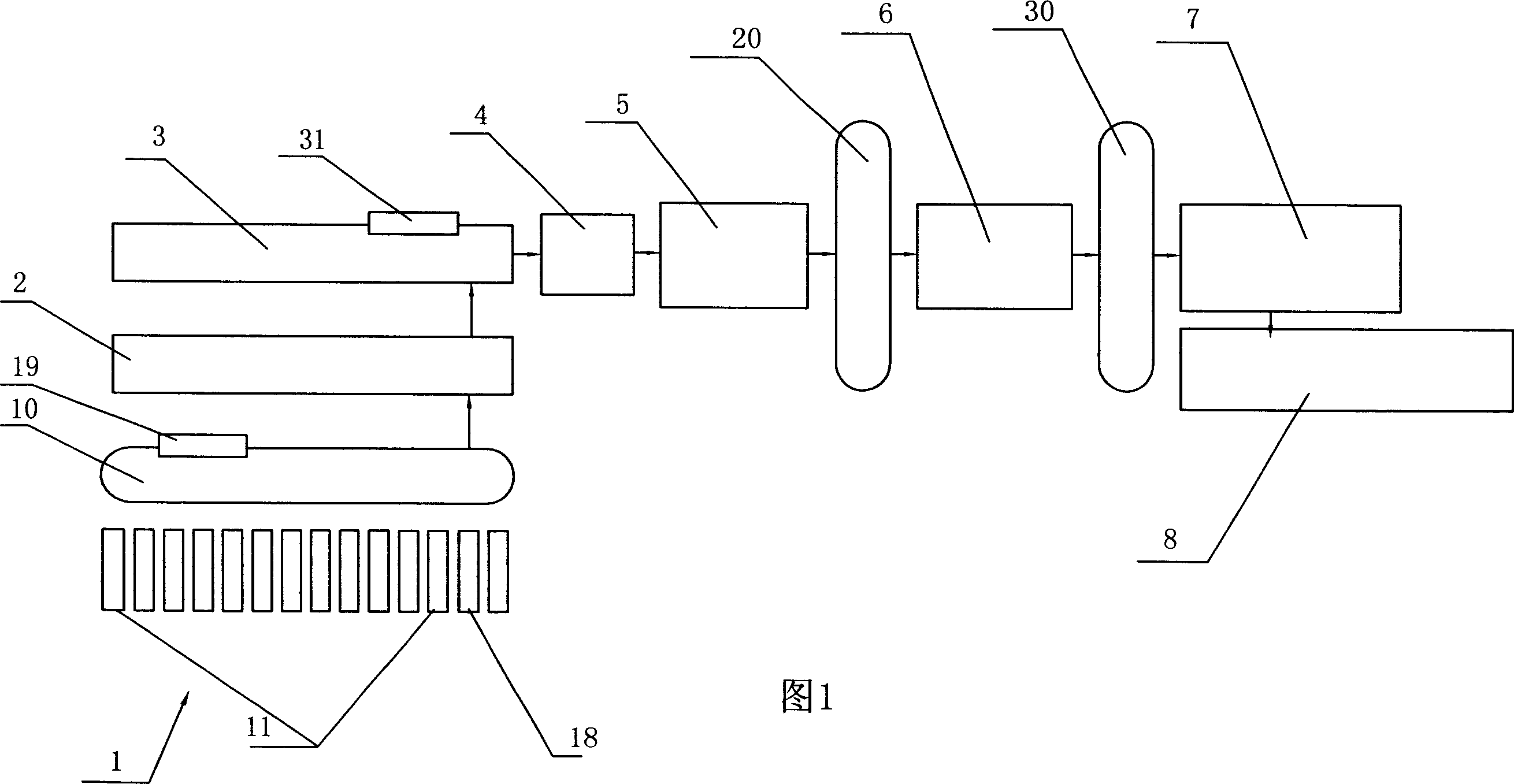

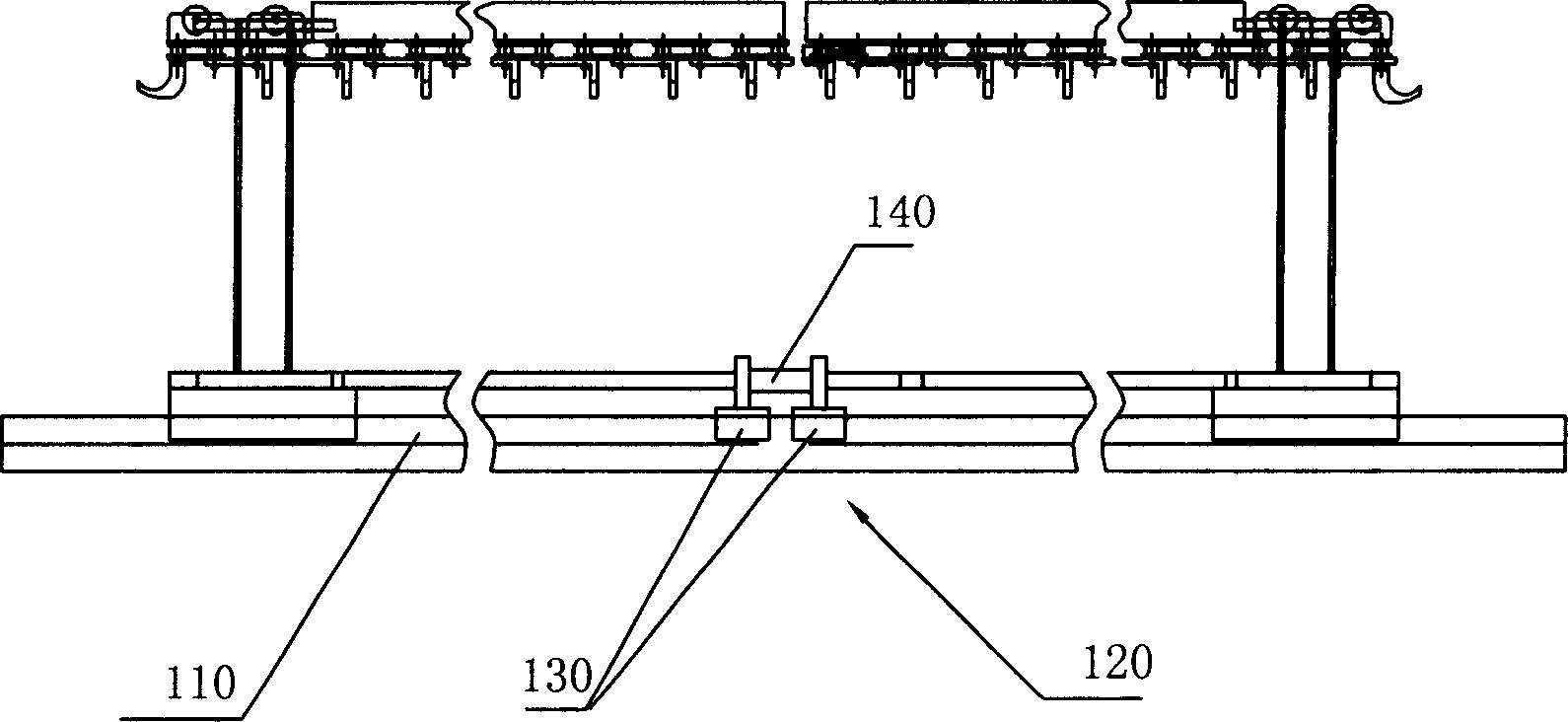

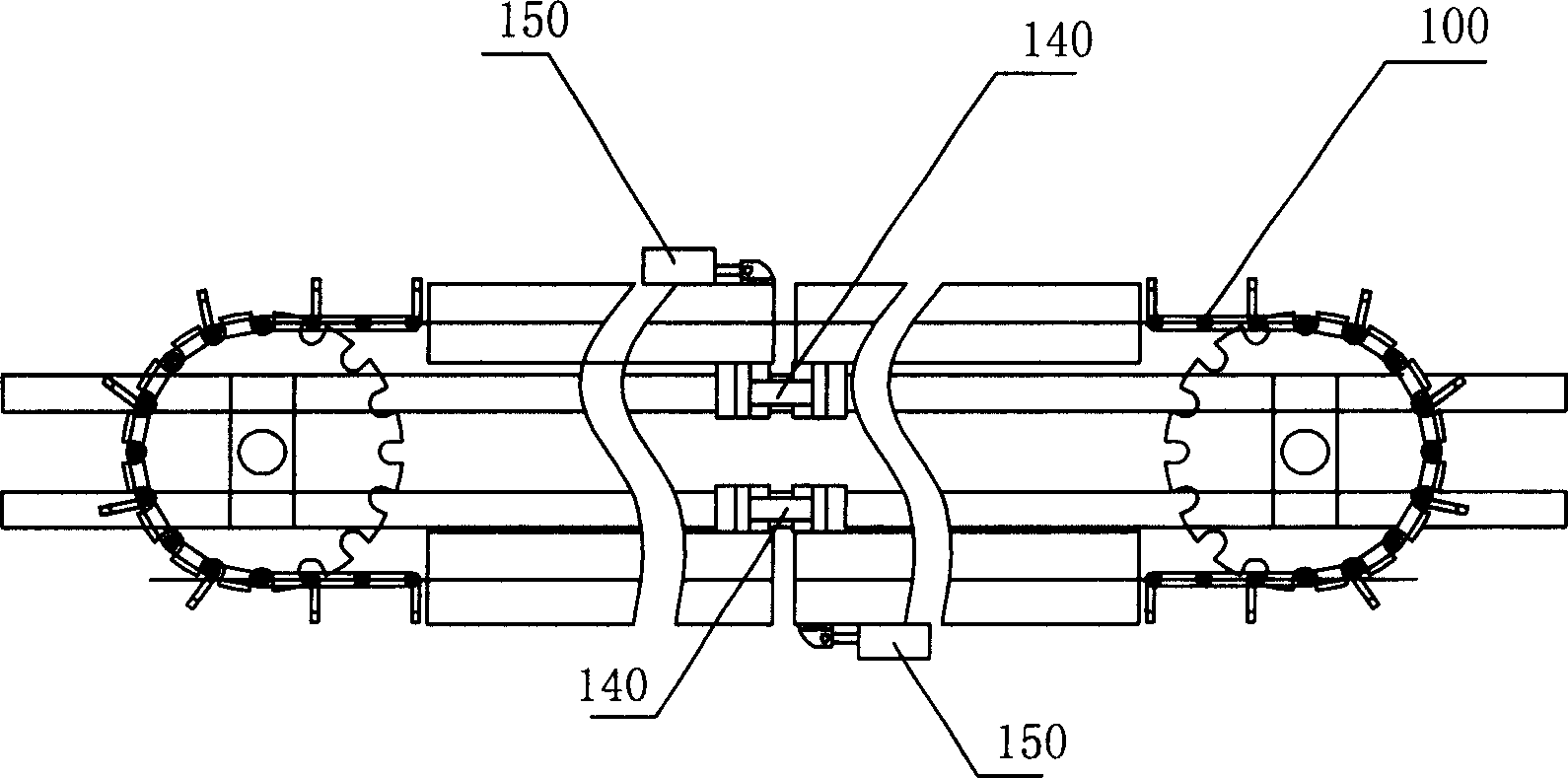

[0023] Embodiment 1: A continuous production device for fluorescent tubes, including a pipe bending device 1, a film coating device 2, a powder coating device 3, a tube baking device 4, a sealing device 5, a bridging device 6, an exhaust device 7 and an aging device 8. The pipe bending device 1 is provided with twelve pipe bending mechanisms 11 in parallel. The pipe bending mechanism 11 includes a heating channel 12 and a pipe bending fixture (not shown). The heating channel 12 is provided with a glass tube inlet 13 and a glass tube outlet 14. The heating A lower burner 15 and an upper burner 16 are arranged in the channel 12 close to the glass tube outlet 14, a hot gas outlet 17 is set in the upper end of the heating channel 12 close to the glass tube inlet 13, and the powder coating device 3 is provided with an automatic coil The powder device 31, the baking tube device 4 is an oven 41 with an upper seal, the inlet 42 and the outlet 43 of the oven 41 are arranged at the botto...

Embodiment 2

[0024] Embodiment 2: Other structures are the same as Embodiment 1, the difference is that the pipe bending device 1 is provided with twelve pipe bending mechanisms 11 and two spare pipe bending mechanisms 18 in parallel, and the sealing device 5 is provided with twelve parallel and synchronous operation The sealing fixture 51, the bridging device 6 is provided with twelve tooling fixtures 61 running side by side and synchronously, the spare pipe bending mechanism 18 has the same structure as the pipe bending mechanism 11, and an automatic Switching mechanism (not shown), when the bending mechanism 11 breaks down, the pipe bending mechanism 11 can be replaced by a spare bending mechanism 18 through an automatic switching mechanism.

Embodiment 3

[0025] Embodiment 3: Other structures are the same as Embodiment 2, except that the hot air outlet 17 is provided with a hot air pipe (not shown) communicating with the film coating device 2 and the powder coating device 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com