Bipolar energy recovering holding circuit and energy recovering holding method thereof

A technology for energy recovery and circuit maintenance, applied to instruments, identification devices, static indicators, etc., can solve the problems of low energy conversion efficiency and reduced power consumption of the whole machine, so as to reduce the power consumption of the whole machine and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

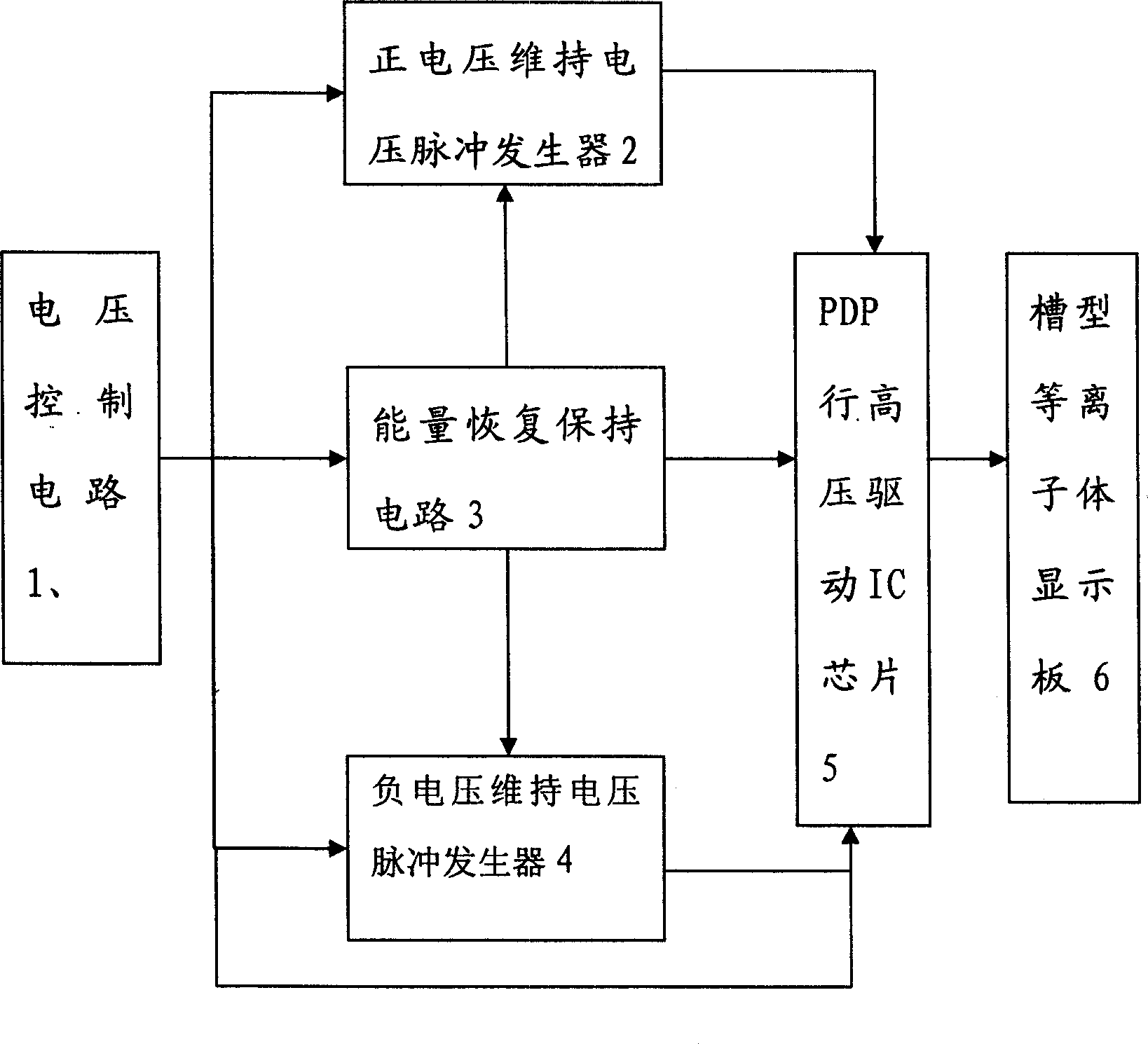

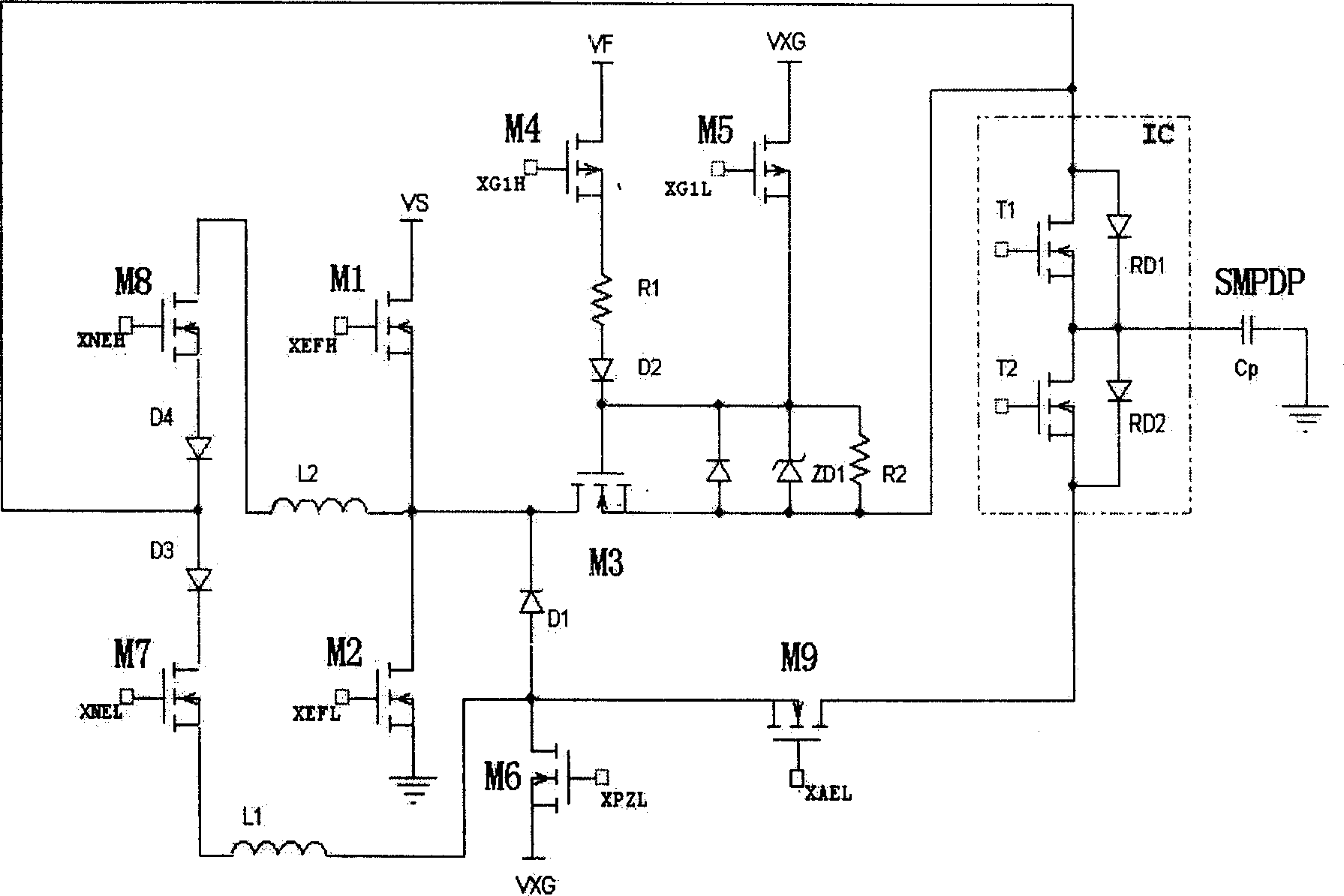

[0014] figure 1 Shown is the structure of the bipolar energy recovery and maintenance circuit, which consists of a voltage control circuit 1, a positive voltage maintenance voltage pulse generator 2, an energy recovery and maintenance circuit 3, a negative voltage maintenance voltage pulse generator 4, a PDP high voltage driver IC chip 5 and a plasma Body display panel 6 is composed. The output terminals of the voltage control circuit 1 are respectively connected to the positive voltage maintenance voltage pulse generator 2, the energy recovery and maintenance circuit 3, the negative voltage maintenance voltage pulse generator 4, and the PDP high-voltage drive IC chip 5, and the output terminals of the energy recovery and maintenance circuit 3 are connected to the positive Voltage maintaining voltage pulse generator 2, negative voltage maintaining voltage pulse generator 4, output terminals of positive voltage maintaining voltage pulse generator 2 and negative voltage maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com