Motor stator

A technology for electric motors and stators, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., and can solve the problems of reduced workability of winding settings, longer winding length, and power line contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

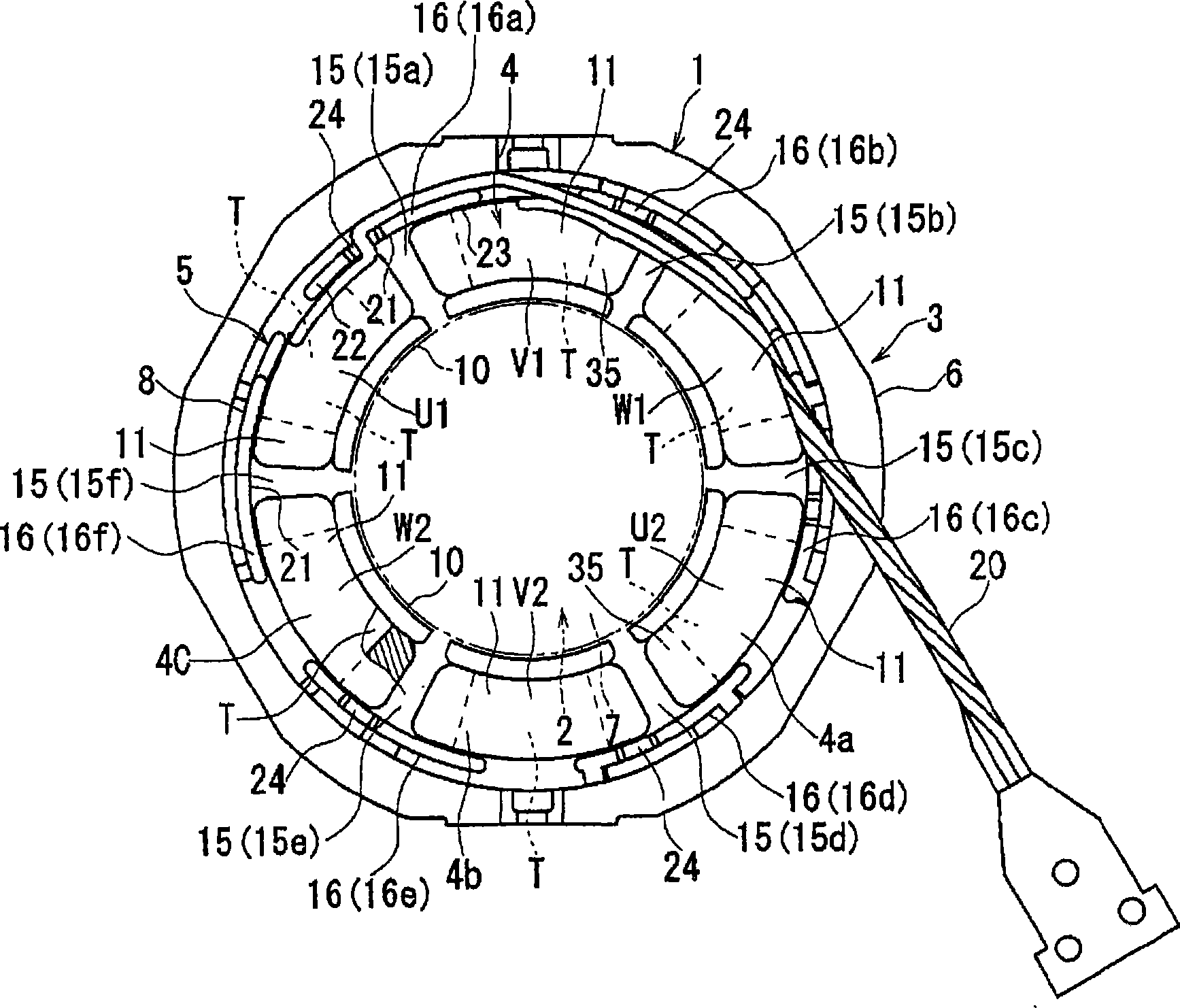

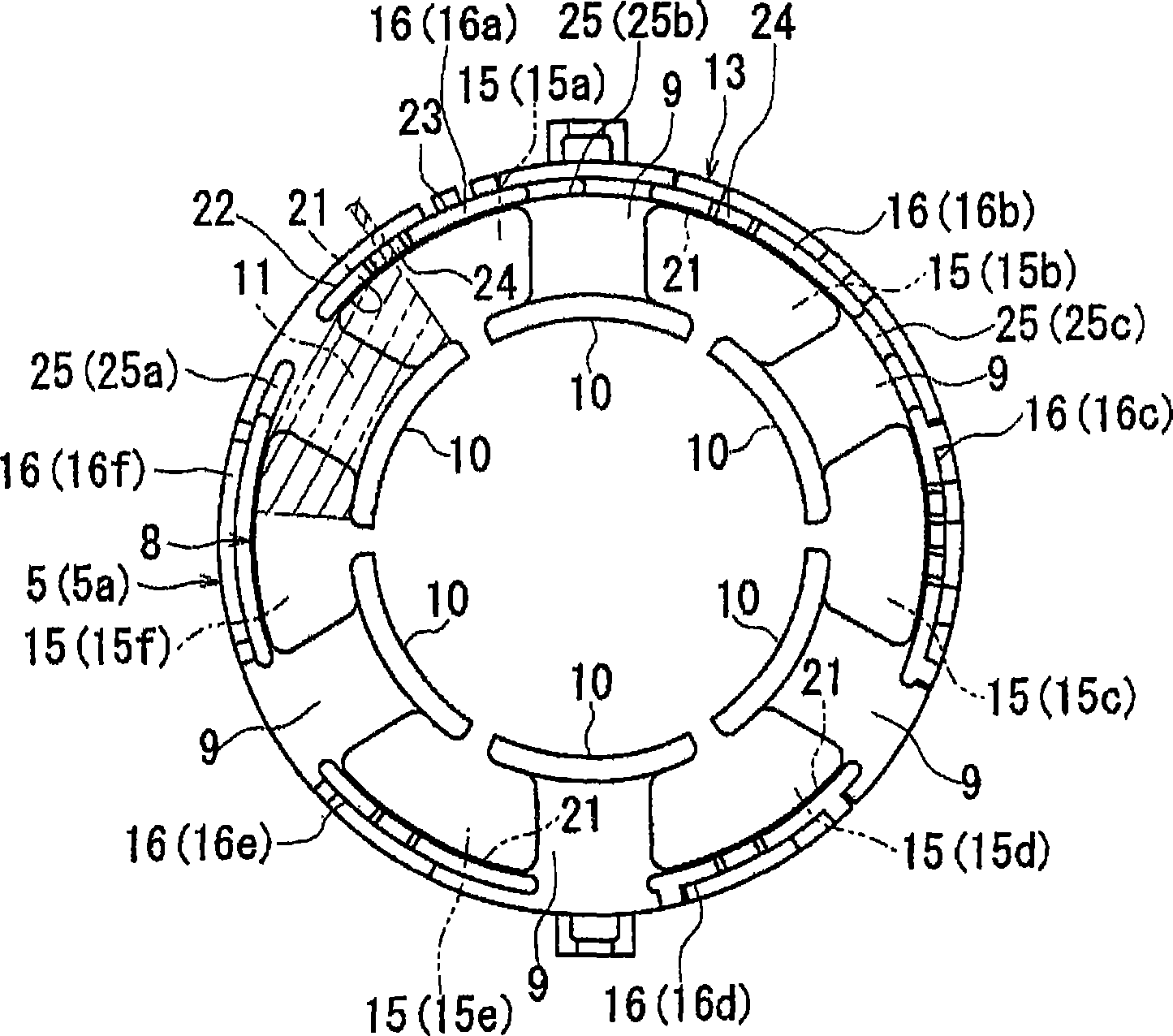

[0015] Hereinafter, specific embodiments of the stator of the motor according to the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic diagram of the main part of the electric motor using this stator. The stator 1, the rotor 2 rotatably embedded in the stator 1, and the like constitute a motor. The stator 1 includes a stator core 3 and a winding 4 wound around the stator core 3 . In addition, the stator core 3 includes: a core body 6 formed by laminating a plurality of annular thin plates made of electromagnetic steel sheets; , 5 (refer to Figure 1 to Figure 3 ). In addition, a plurality of (six in this case) teeth T, . At this time, grooves 15, . . . are formed between adjacent teeth T, T in the circumferential direction. In addition, in this case, there are six grooves 15, that is, the first groove 15a to the sixth groove 15f.

[0016] In addition, the rotor 2 has a rotor core 7 and a plurality of magnets (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com