Method for making building engineering pile and apparatus used thereof

A technology of construction engineering and production method, which is applied in construction, infrastructure engineering, sheet pile wall and other directions, can solve the problems of difficult to control the injection amount of super-fluid concrete, untidy construction on site, excessive waste, etc., and achieves low engineering cost. , The effect of improving the support force and increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example I

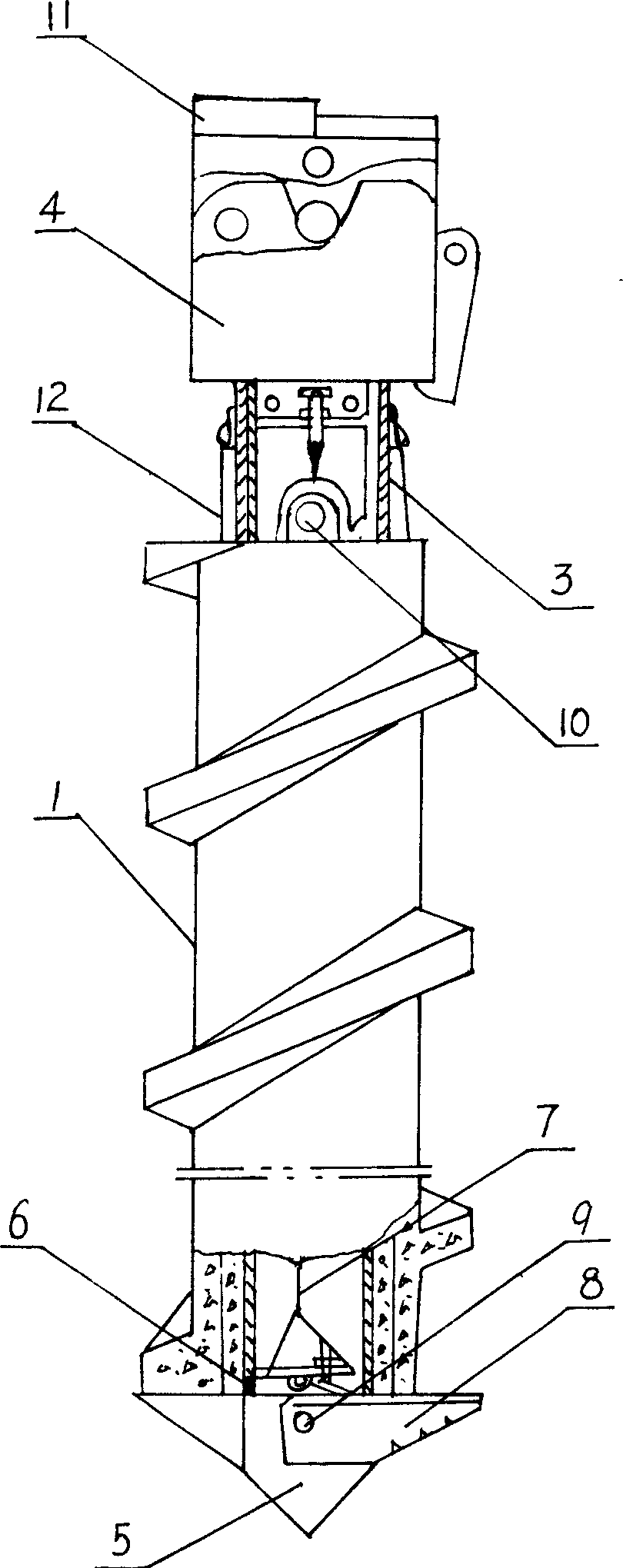

[0031] Engineering example I: According to geological conditions, design requirements, equipment status, screw pile inventory and production speed, flexible selection can be carried out for pile connection operations.

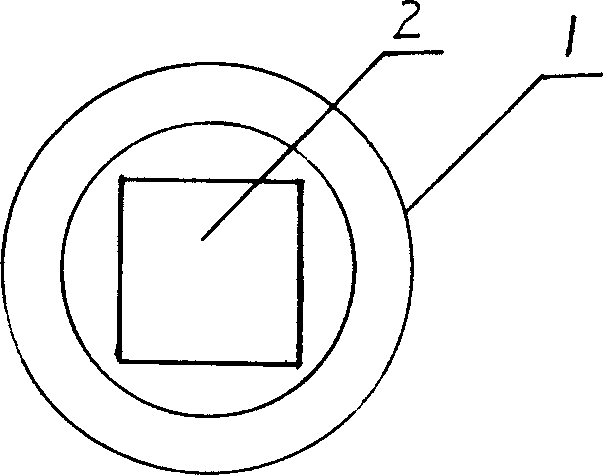

[0032] Using Φ400 spiral prefabricated piles, the geological conditions are as follows: 0.8~1.8M is plain fill (medium density), 1.8~2.6M is loamy soil (medium density), 2.6~5.1M is clay (hard plastic), 5.1~5.8M is medium sand (medium density), 5.8 ~ 12M is garden gravel (medium density). According to the geological report, the length of the selected pile is 7M core hole alignment spiral prefabricated pile, and the drill tip is open type. When drilling to 2m during operation, it is difficult to advance the footage, and there is a phenomenon of suffocation in the further advance. At this time, the pressure water of the injection belt is greatly improved, and the advance is smoother. The soil is obviously moist and naturally falls off from the screw pitch. When t...

example II

[0034] The plane size of the foundation pit is 110M×60M. The original design uses Φ600 superfluid helical bored piles, with a center distance of 1.2M, a total of 278 piles, a pile length of 15M, and a top-loading beam (handle beam) of 400MM×600MM. The construction cost is more than 1 million yuan, the consumption of steel is 90 tons, and the cement is 600 tons. Instead, use Φ500 type core holes and spiral prefabricated piles at the same head. The length of the pile is 15M, and the number of piles is still 278. The handle beam uses section steel to fasten the pile core section steel. The total cost is 550,000 yuan, the steel consumption is 30 tons, and the cement consumption is 230 tons. Synthetic fiber consumption is 410 kg. Compared with saving 45% of funds, 66% of steel products and 62% of cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com