Electric connector with flexible electric circuit interface

A technology of flexible circuits and electrical connectors, applied in the direction of circuits, connections, parts of connection devices, etc., can solve problems such as increased thickness, reduced space of the seat body 10, and difficulty in manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The above and other objects, advantages and features of the present invention can be more clearly understood from the following detailed description of the preferred embodiments with reference to the drawings.

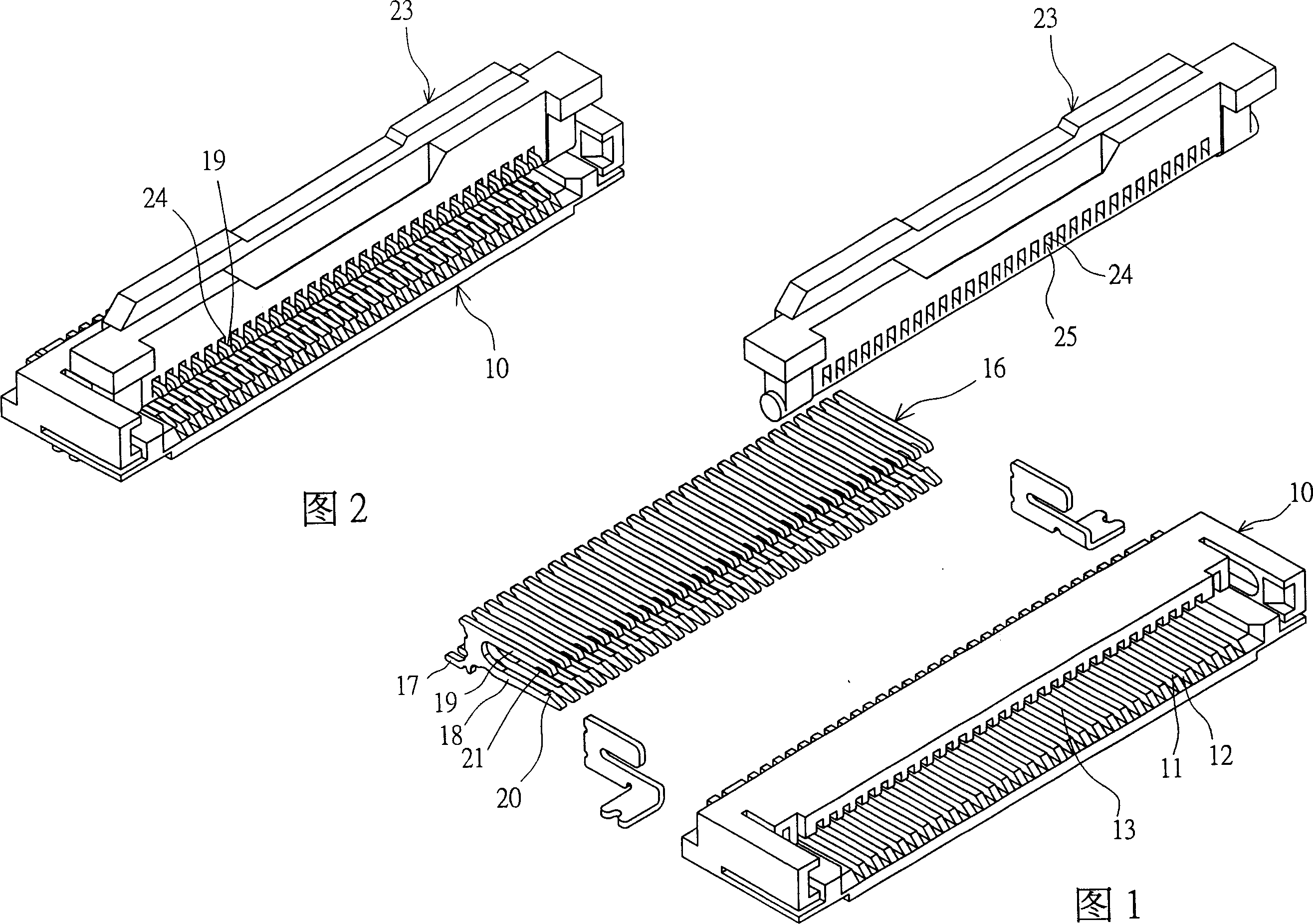

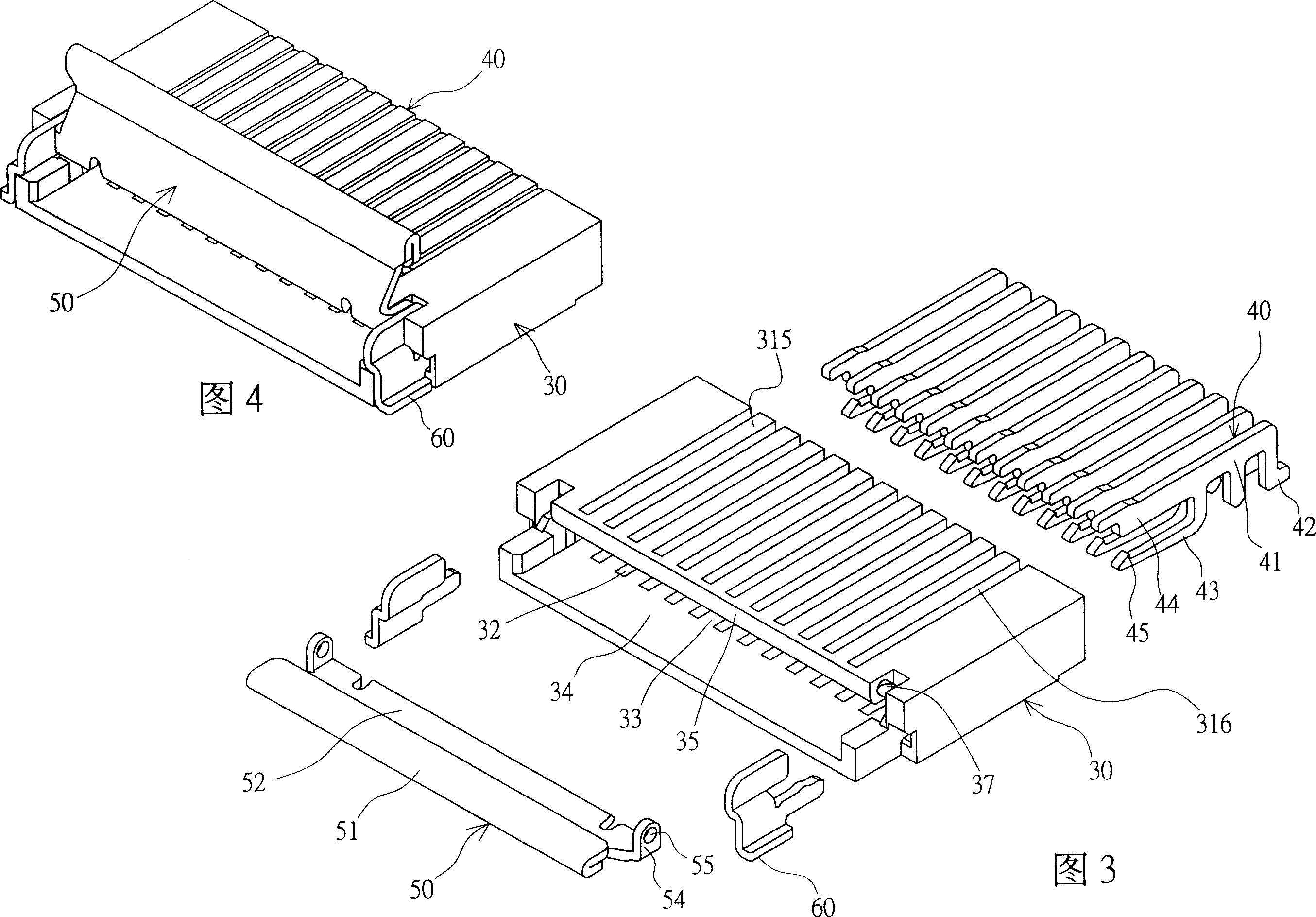

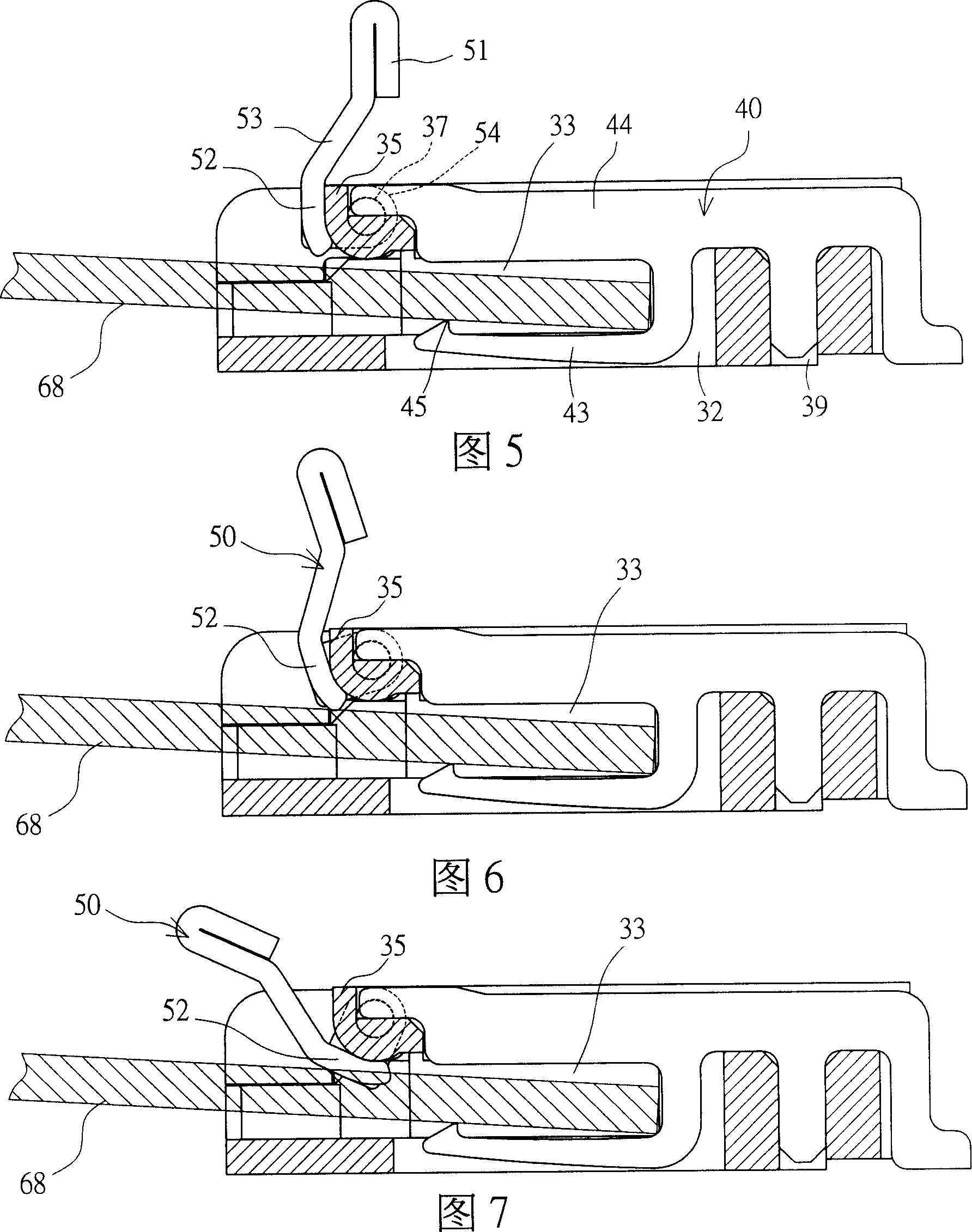

[0066] Referring to Fig. 3, Fig. 4 and Fig. 5, the present invention includes a base body 30, a plurality of terminals 40, a flip cover 50 and two welding pads 60, wherein:

[0067] The seat body 30 is made of plastic material, and a plurality of terminal grooves 32 and a connection groove 33 arranged at equal intervals are arranged inside it. soft flat cable) is inserted, and above the front end of the connecting groove 33, a pressing plate 35 with an arc surface is provided, and a pivot 37 is respectively provided on both sides of the connecting groove 33 of the pressing plate 35, and the arc surface of the pressing plate 35 is connected to the The pivots 37 are concentric, and each terminal slot 32 is provided with a card slot 39. The upper plate surface 315 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com