Petroleum hydrocabon cracking catalyst and its production

A cracking catalyst and catalyst technology, applied in cracking, petroleum industry, catalytic cracking, etc., can solve problems such as poor selectivity of linear hydrocarbon isomerization, achieve reduced olefin content, good linear olefin isomerization catalytic performance, and improve The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

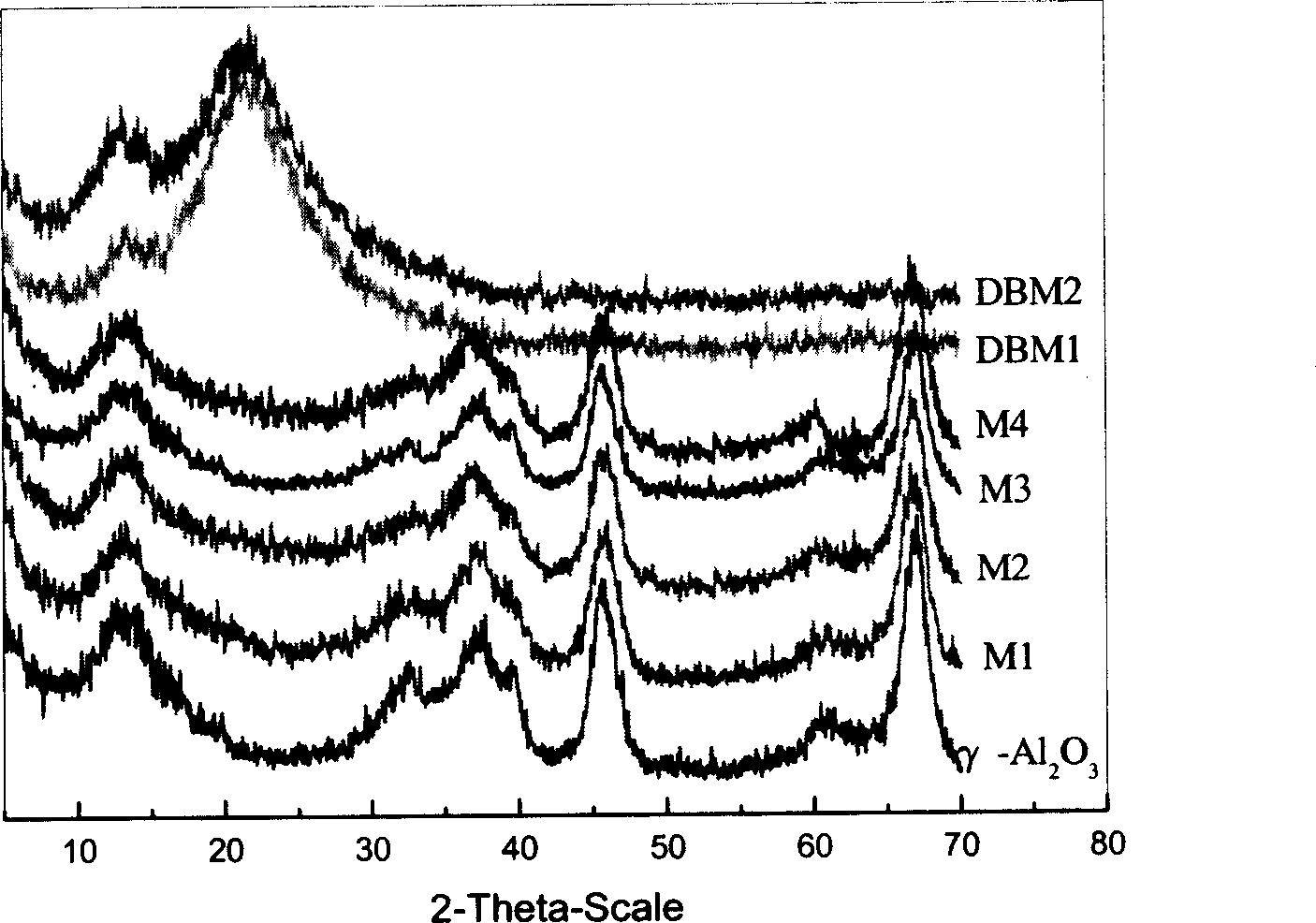

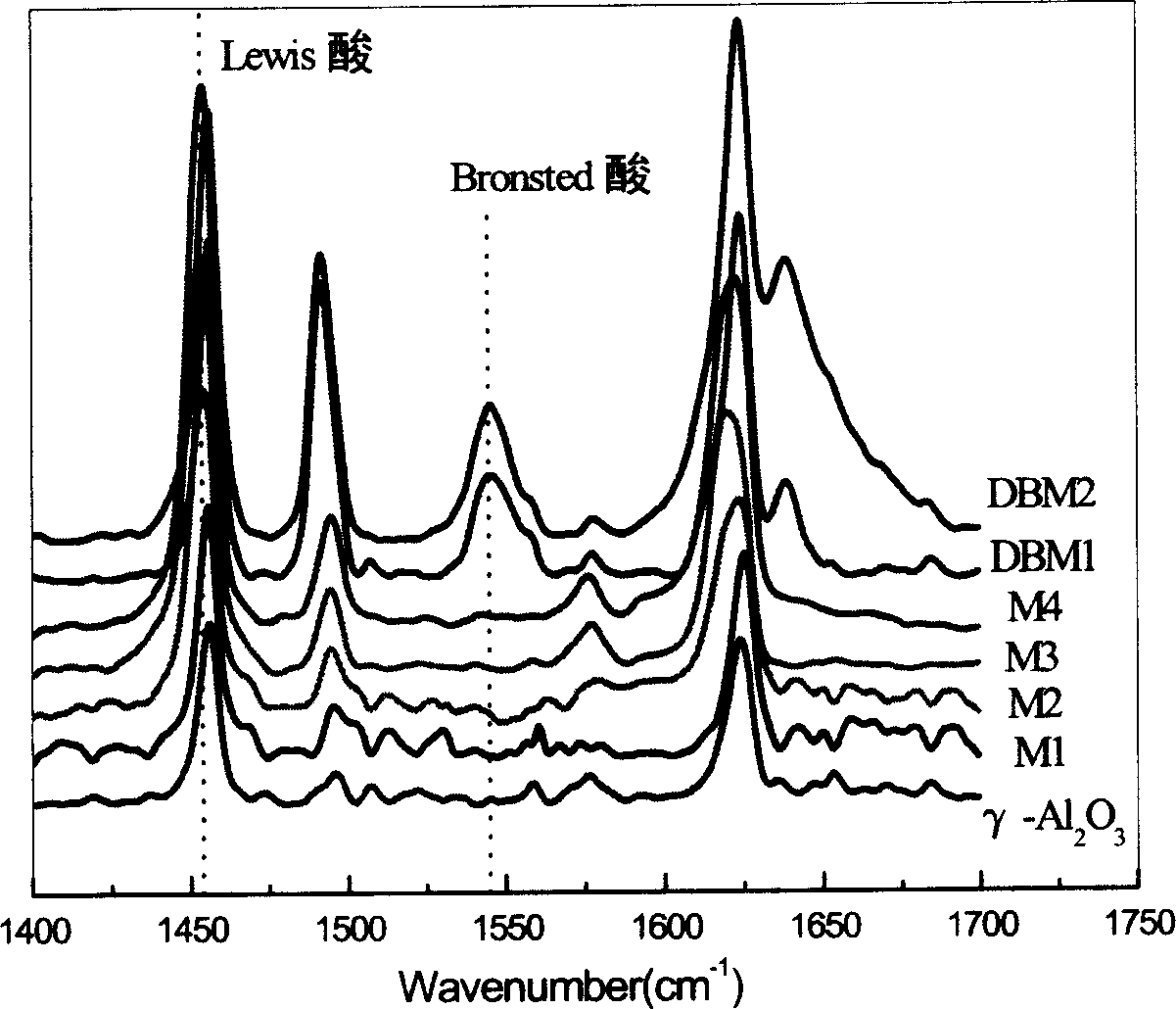

[0044] The silica modified alumina composition provided by the invention is prepared.

[0045] 500 g deionized water and 506.5 g AlCl 3 ·6H 2 16.1 grams of water glass solution (Shandong Aluminum Factory, SiO 2 content is 20.6%), reacted at room temperature for 30 minutes, then added dropwise 1:1 ammonia water (Beijing Chemical Plant, analytically pure) to adjust the pH value until a gel was formed, and its pH value was 4.5, and continued to stir and heat up to 65°C , stop stirring and age for 1 hour, vacuum filter. The filter cake was reslurried with decationized water at 60°C for 20 minutes and vacuum filtered. So repeated washing 3 times, to obtain the modified composition M 1 . Its chemical composition, physicochemical properties and surface acidity measured by pyridine adsorption infrared spectroscopy are listed in Table 1.

Embodiment 2

[0047] Preparation of the silica-modified alumina composition provided by the invention.

[0048] 500 g deionized water and 475.2 g AlCl 3 ·6H 2 Slowly add 48.2 grams of water glass solution dropwise to the solution of O, react at room temperature for 25 minutes, then add dropwise 1:1 ammonia water to adjust the pH value until a gel is formed, and its pH value is 4.8, continue to stir and heat up to 60°C , stop stirring and age for 1.5 hours, vacuum filter. The filter cake was reslurried with 70°C decationized water for 25 minutes and vacuum filtered. So repeated washing 3 times, to obtain the modified composition M 2 . Its chemical composition, physicochemical properties and surface acidity measured by pyridine adsorption infrared spectroscopy are listed in Table 1.

Embodiment 3

[0050] Preparation of the silica-modified alumina composition provided by the invention.

[0051] 500 grams of deionized water and 454.5 grams of AlCl 3 ·6H 2 Slowly add 69.6 grams of water glass solution to the solution of O, react at room temperature for 30 minutes, then add dropwise 1:1 ammonia water to adjust the pH value until a gel is formed, and its pH value is 5.5, continue to stir and heat up to 70°C , stop stirring and age for 1.5 hours, vacuum filter. The filter cake was reslurried with 65°C decationized water for 30 minutes and then vacuum filtered. So repeated washing 3 times, to obtain the modified composition M 3 . Its chemical composition, physicochemical properties and surface acidity measured by pyridine adsorption infrared spectroscopy are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com