Electronic circuit component mounter

A technology for electronic circuits and installation machines, which is applied in the direction of electrical components, electrical components, measuring devices, etc. It can solve problems such as insufficient pressing force, damage to electronic circuit components or suction nozzles, and unsuitable installation, and achieve the effect of avoiding failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] Embodiments of the present invention will be described in detail below according to the accompanying drawings.

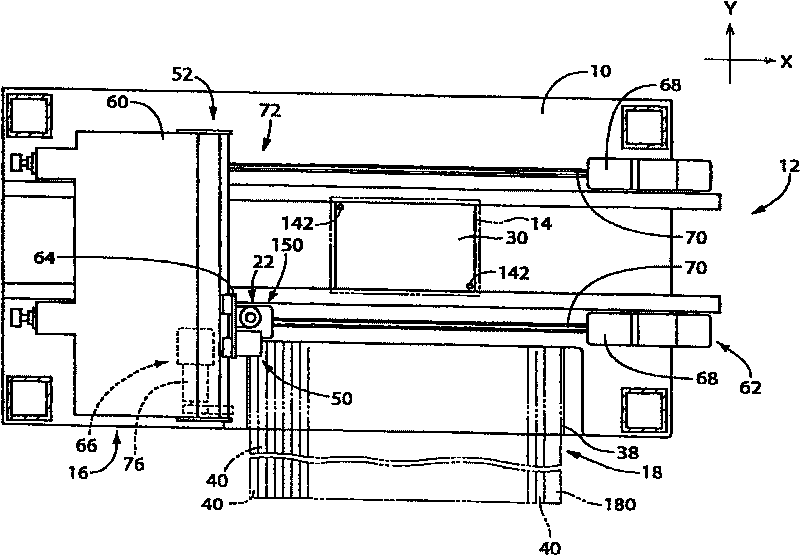

[0104] figure 1 An electronic circuit component mounting machine which is an embodiment of the present invention is shown. This electronic circuit component mounting machine moves the mounting head to an arbitrary position in a plane parallel to the surface of the printed circuit board, receives electronic circuit components from a component supply device, and mounts them on the printed circuit board, for example, as described in Japanese Patent No. 2824378 Publication No. 1, etc., it will be briefly described below.

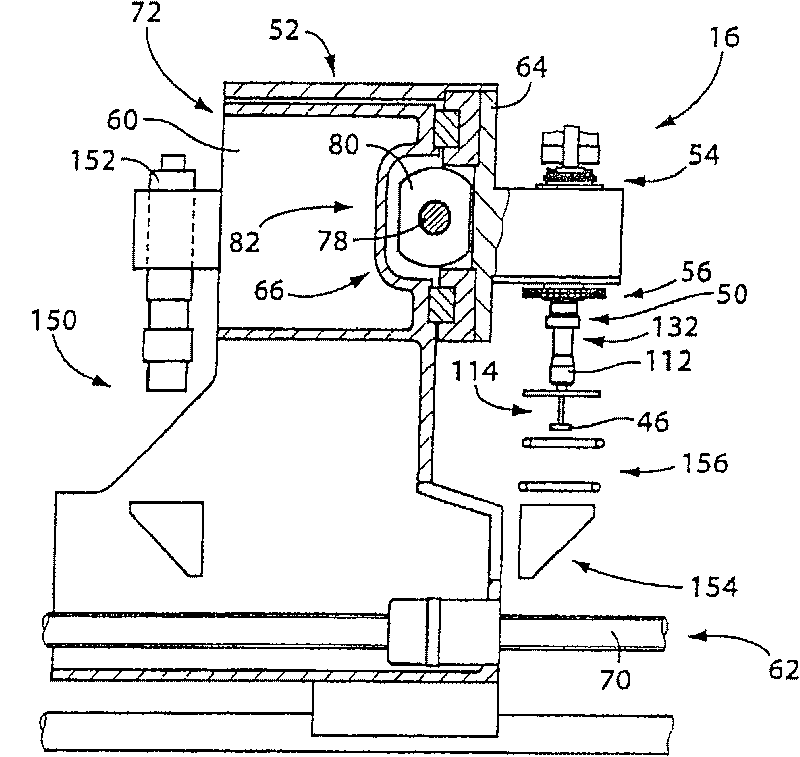

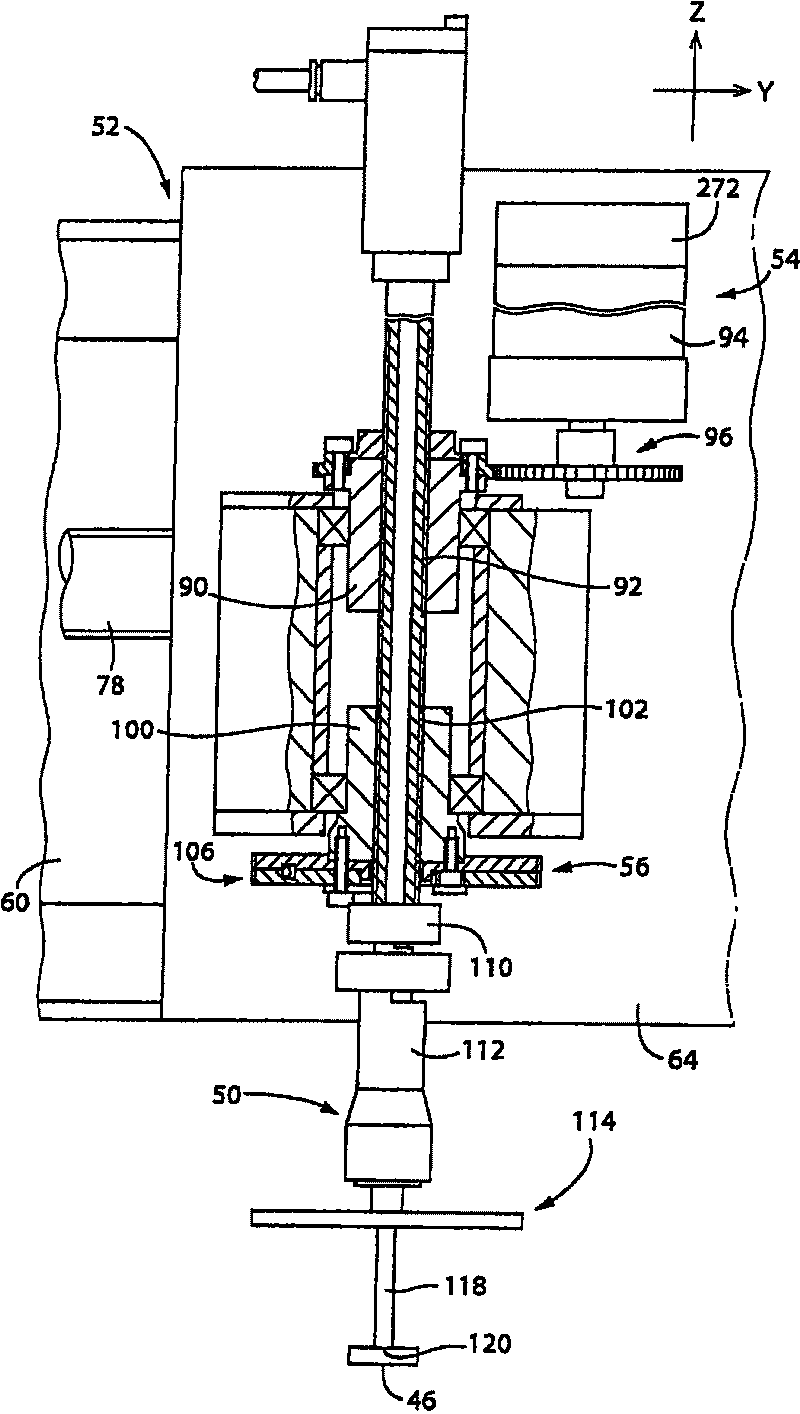

[0105] Such as figure 1 and figure 2 As shown, the electronic circuit component mounting machine 1 includes a pedestal 10 constituting the main body of the mounting machine, a circuit board conveying device 12 arranged on the pedestal 10, a printed circuit board holding device 14, a component mounting device 16, a component supply device 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com