Rotary wing helicopter

A helicopter and rotor technology, applied in the field of rotor helicopters, can solve problems such as waste of engine power, low lift efficiency, torsional vibration and operation response lag, and achieve the effects of increasing payload, increasing safety and reliability, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

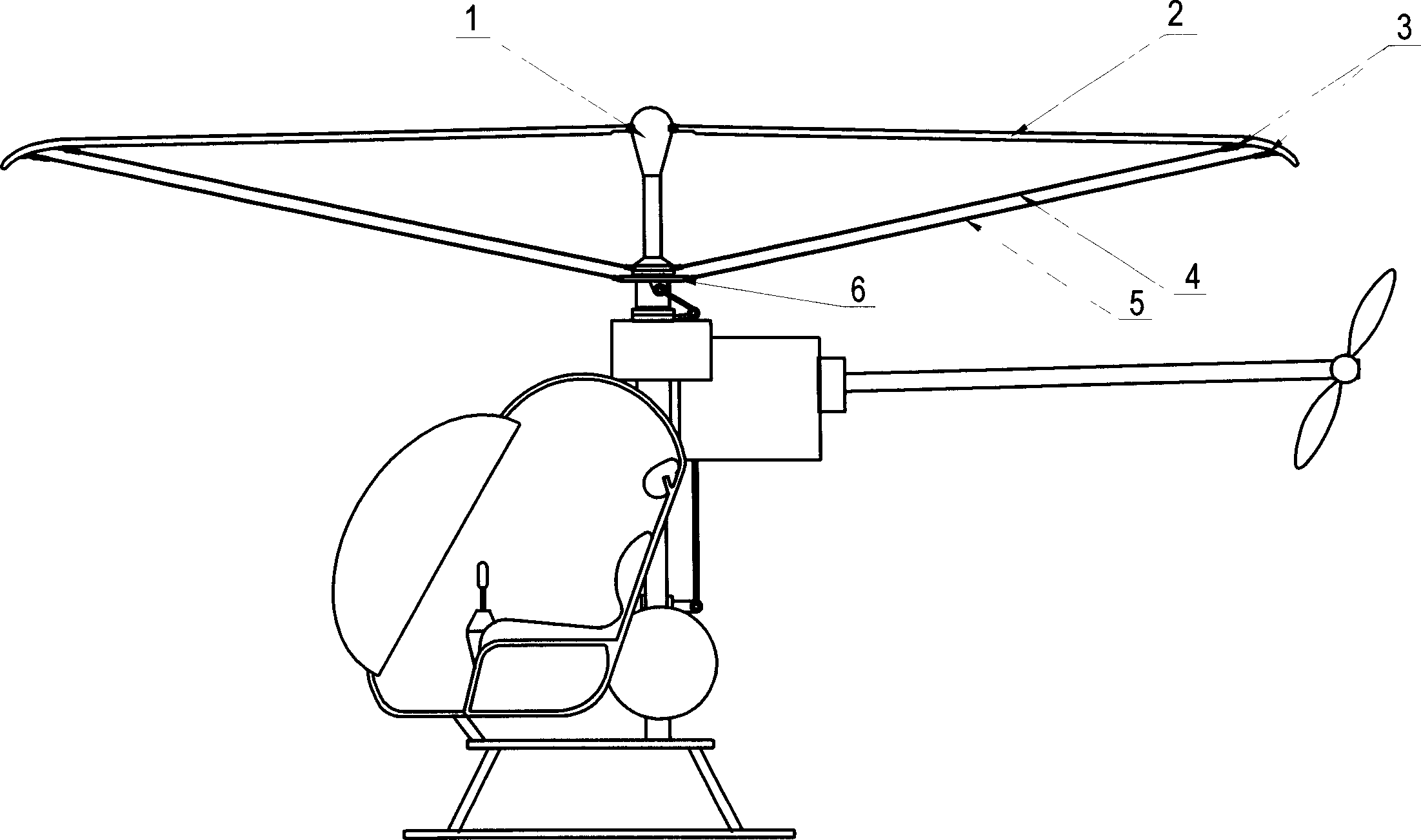

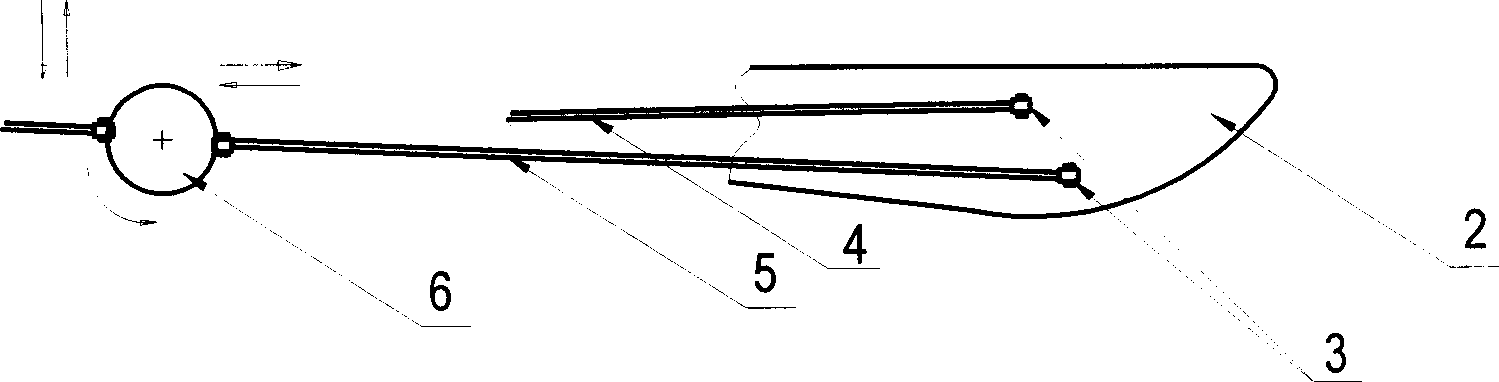

[0016] see figure 1 and figure 2 , is a preferred embodiment of the present invention, the helicopter of the canopy rotor track of the present invention has rotor 2 and rotating propeller hub 1, and the root of rotor 2 is hinged on the upper end of propeller hub 1, and at the outer end of rotor 2 and paddle At least one connecting piece 4 is connected between the hubs 1, the connecting piece 4 can be a tension cable or a connecting rod, and its two ends are respectively hinged on the outer end of the rotor 2 and the lower end of the propeller hub 1, during work, the rotor 2 and connecting piece 4 rotate together with the propeller hub 1.

[0017] A control ring 6 is also arranged below the above-mentioned propeller hub 1. The control ring 6 is a translational control ring, which rotates synchronously with the propeller hub 1 and can translate on the vertical plane of the rotating shaft at the same time, so that the rotor 2 can move in the whole The lift force on each sector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com