Process and extruder nozzle for producing tubular extruded products

An extruder and nozzle technology used in the production of tubular extruded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

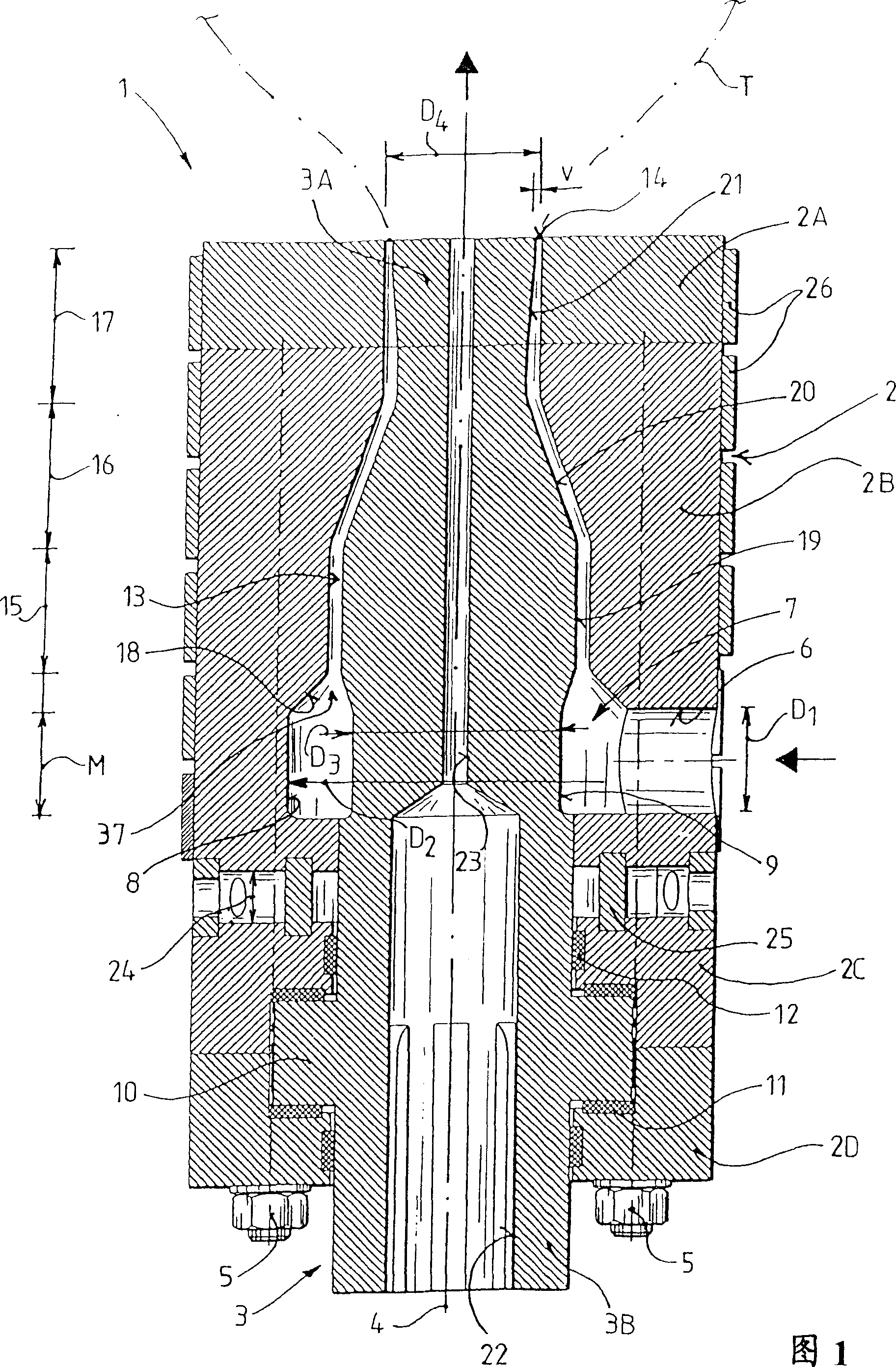

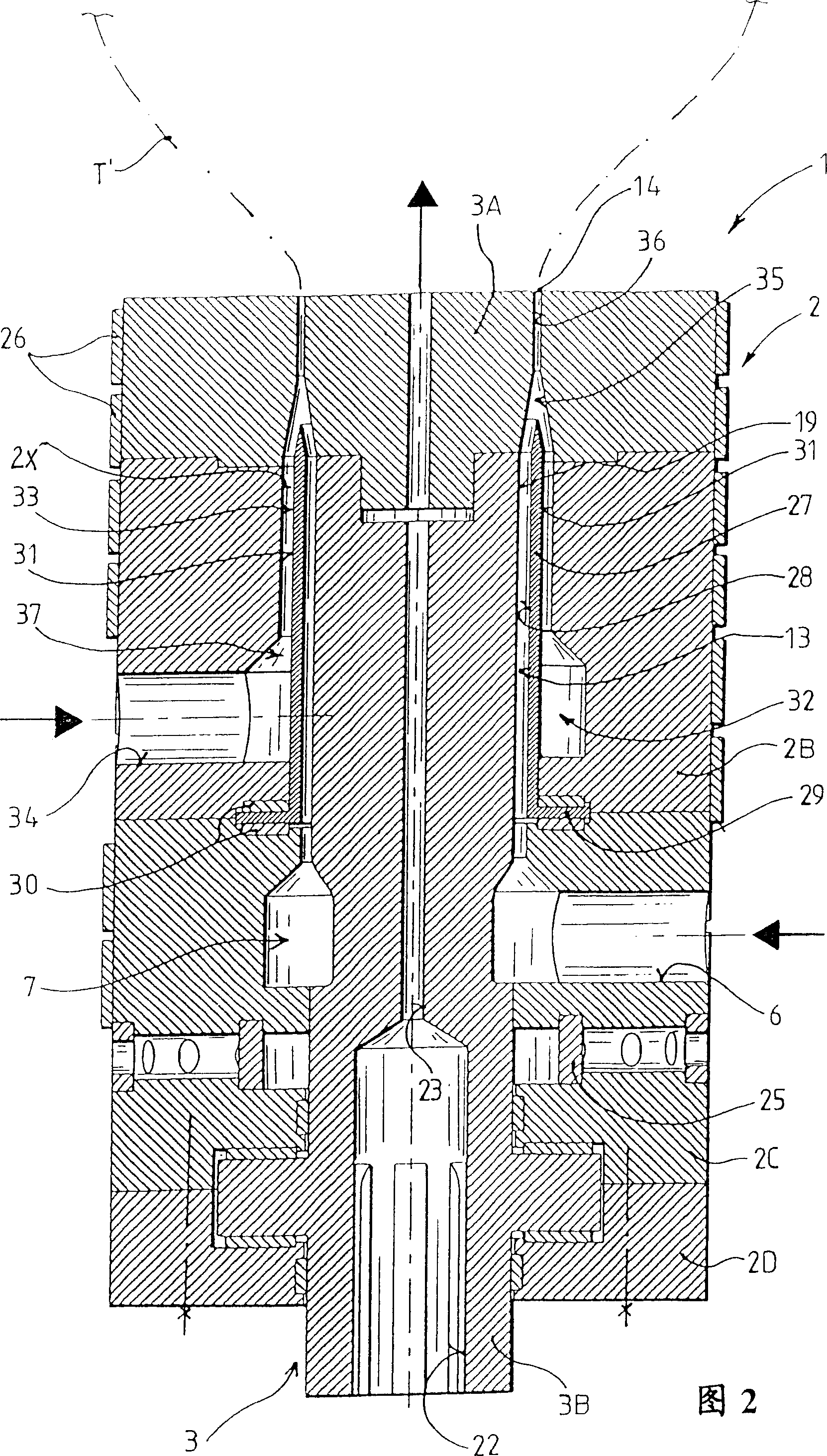

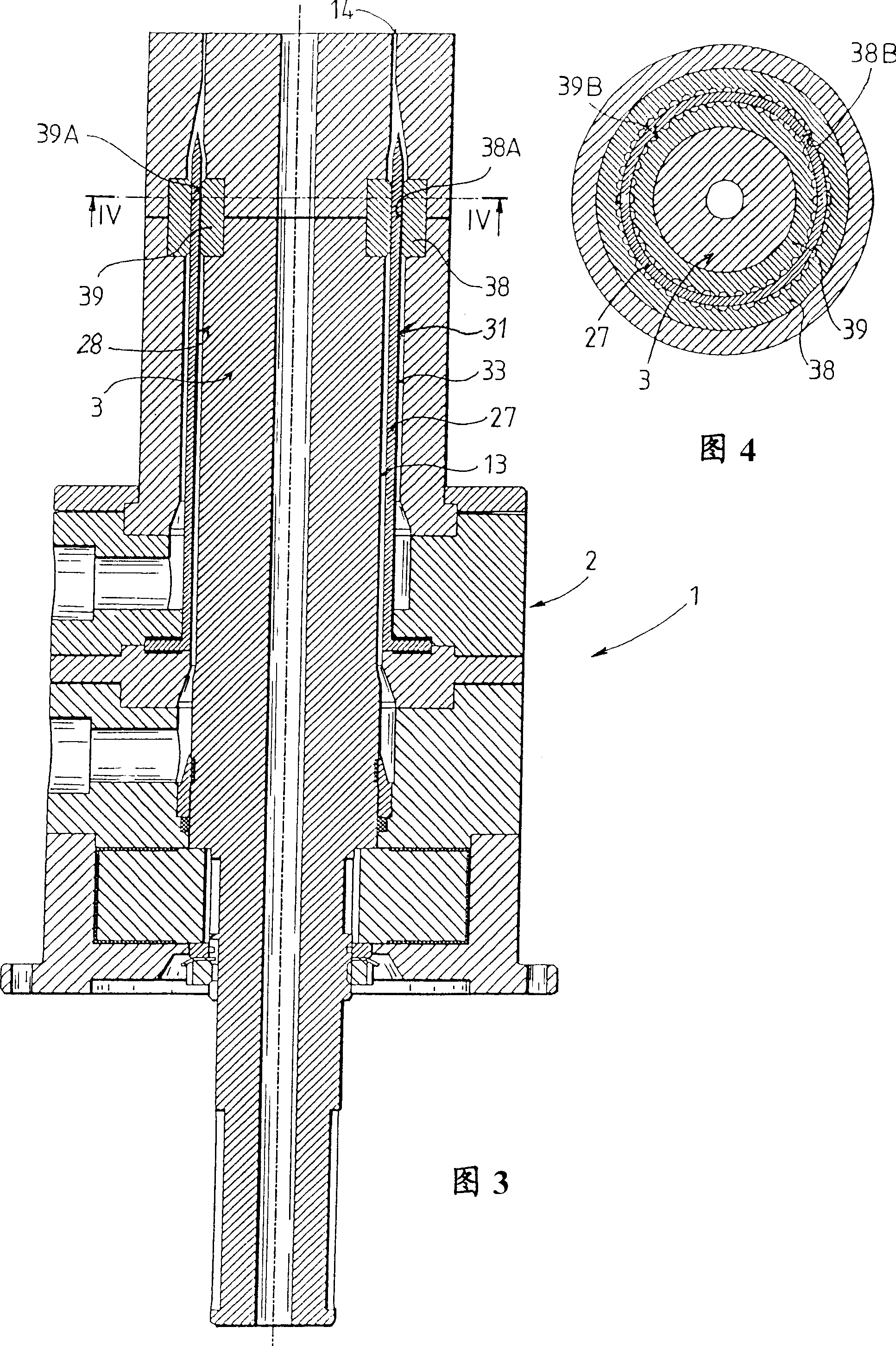

[0033] As shown in FIG. 1, the extruder nozzle 1 according to the present invention can be used to extrude a single-layer film hose, which can be used as a packaging film. The extruder nozzle 1 comprises two main parts, an outer nozzle part 2 and an inner nozzle core 3 relatively rotatably embedded in the outer nozzle part 2 . In the present example, the outer nozzle part 2 is arranged in a fixed manner and is formed as a substantially rotationally symmetrical element, ie as a cylindrical housing with a vertical longitudinal axis 4 .

[0034] In the present example, the outer nozzle part 2 is axially divided and comprises an upper part 2A, middle parts 2B and 2C, and a lower part 2D, arranged coaxially with respect to the longitudinal axis 4 and connected to each other in a detachable manner by 5 screws. Fixed and centered. The middle part 2B of the outer nozzle part 2 is provided with a radial inlet 6 through which molten thermoplastic such as polyethylene is supplied under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com