Electronic part feeder

A technology for electronic component supply and component application in the direction of electrical components, electrical components, etc., which can solve the problems of broken cover tape, inability to absorb electronic components, and inability to peel off stable cover tape, so as to avoid adsorption errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below with reference to the drawings.

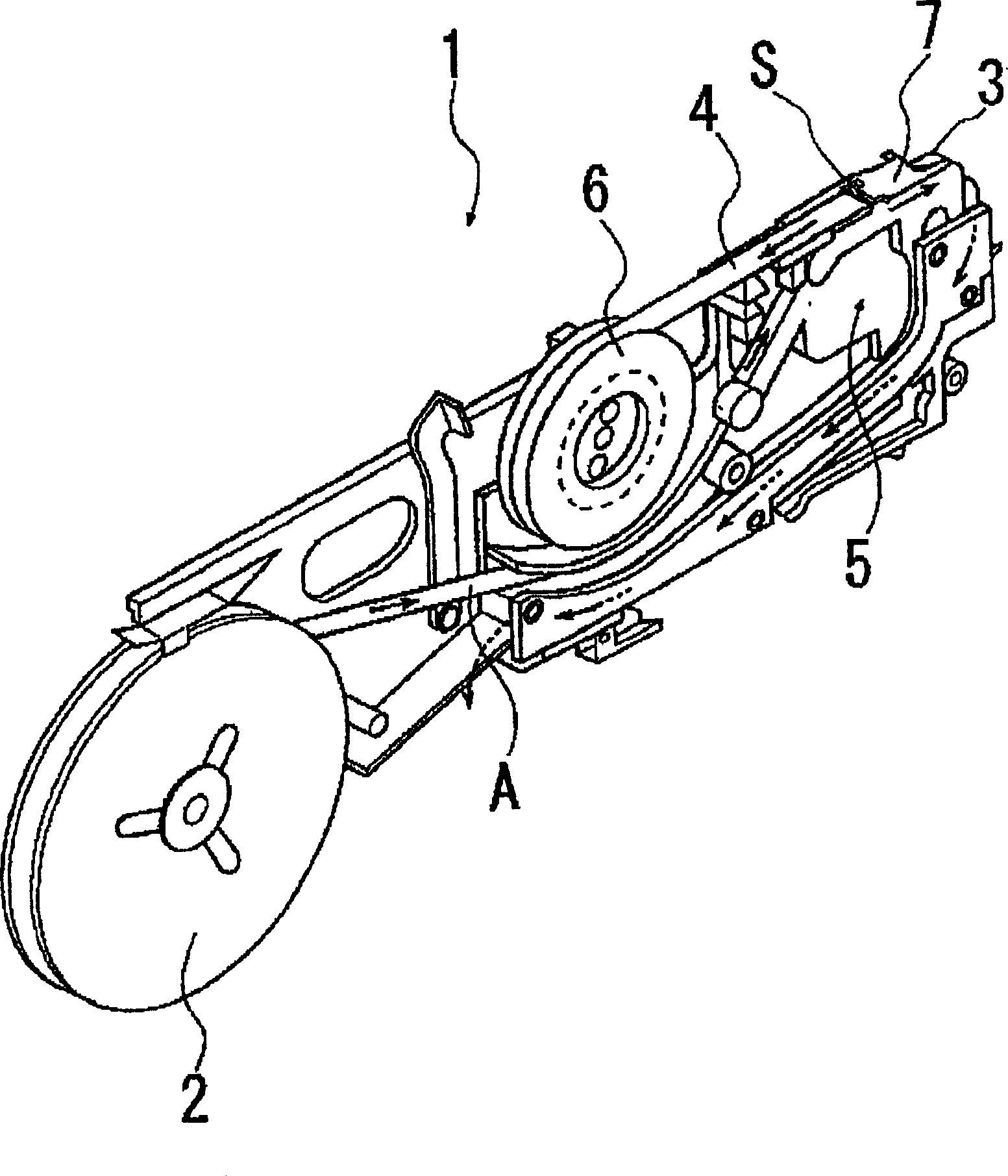

[0020] Such as figure 1 As shown, the parts supply device 1 of the present invention has: a take-up reel (reel) 2, which is detachably installed on the feeder (feeder bank) main body (not shown), for winding parts conveyor belt A; A conveying mechanism 5 for sending out a component conveying tape A composed of a carrier tape 3 and a cover tape 4 in a conveying direction; and a recovery take-up reel 6 for peeling and recovering the cover tape 4 from the carrier tape 3 .

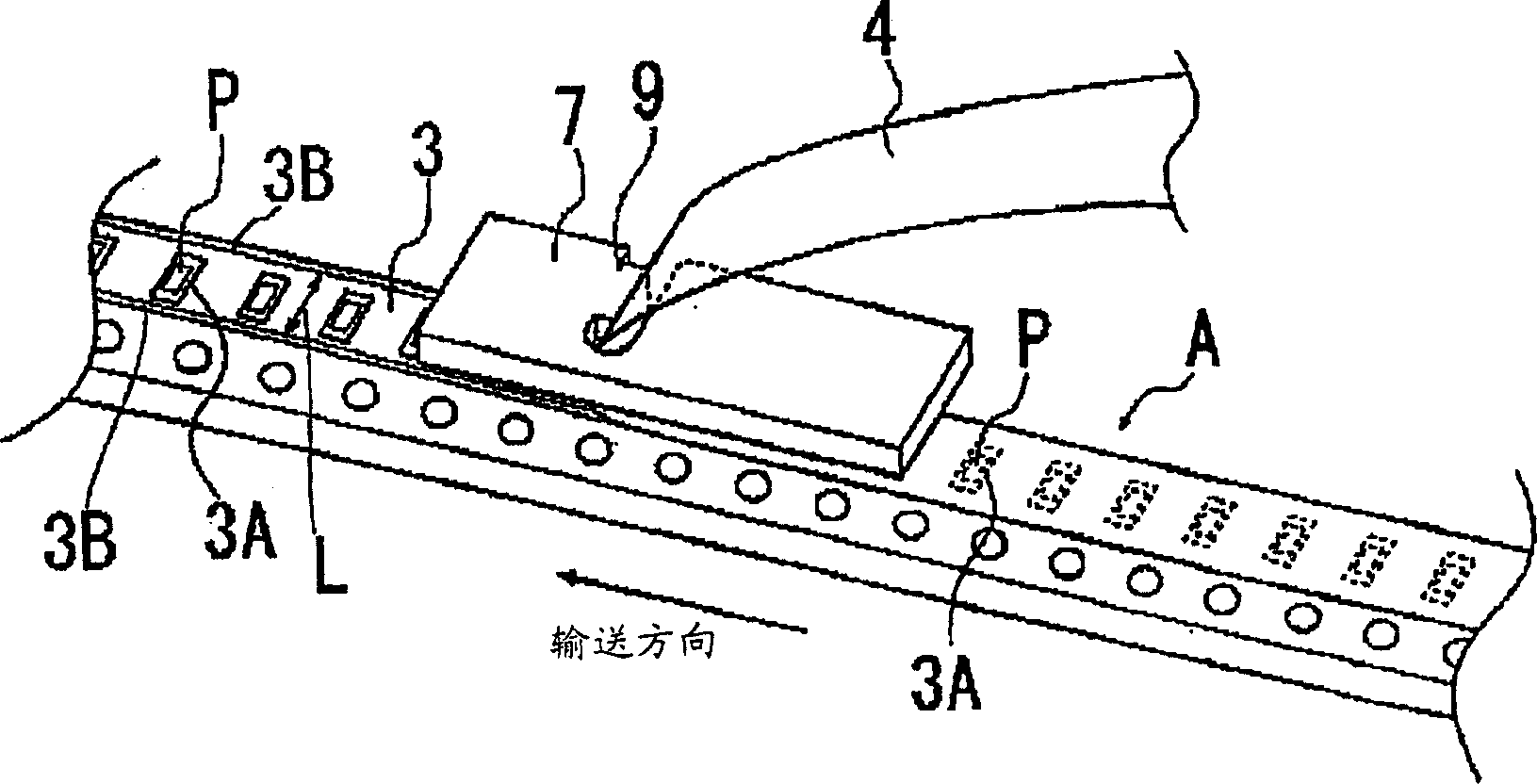

[0021] Such as figure 2 As shown, the carrier tape 3 stores all the electronic components P in a certain direction one by one in the storage chamber 3A formed at a certain pitch, and the cover tape 4 is spaced from the predetermined space on both sides of the carrier tape 3 in the longitudinal direction. The bonding portions 3B formed at intervals L are bonded to prevent movement or falling off. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com