Process for synthesizing sec-butyl urea

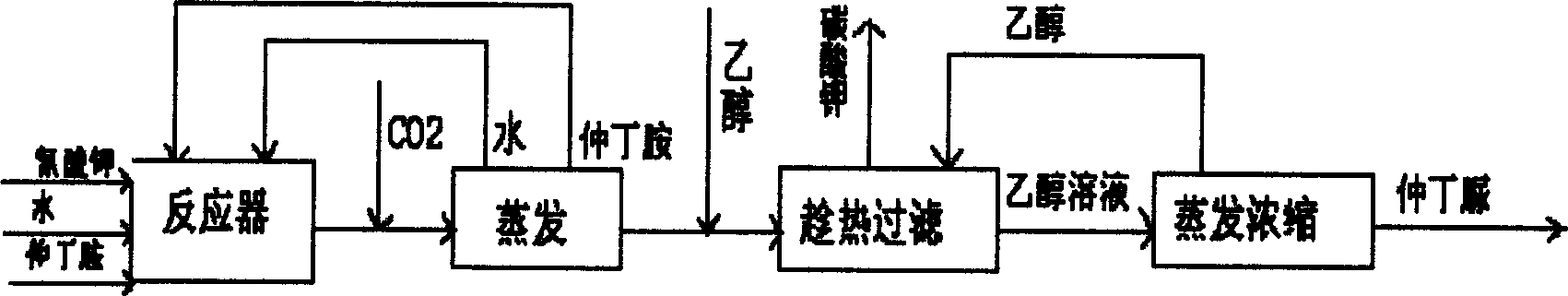

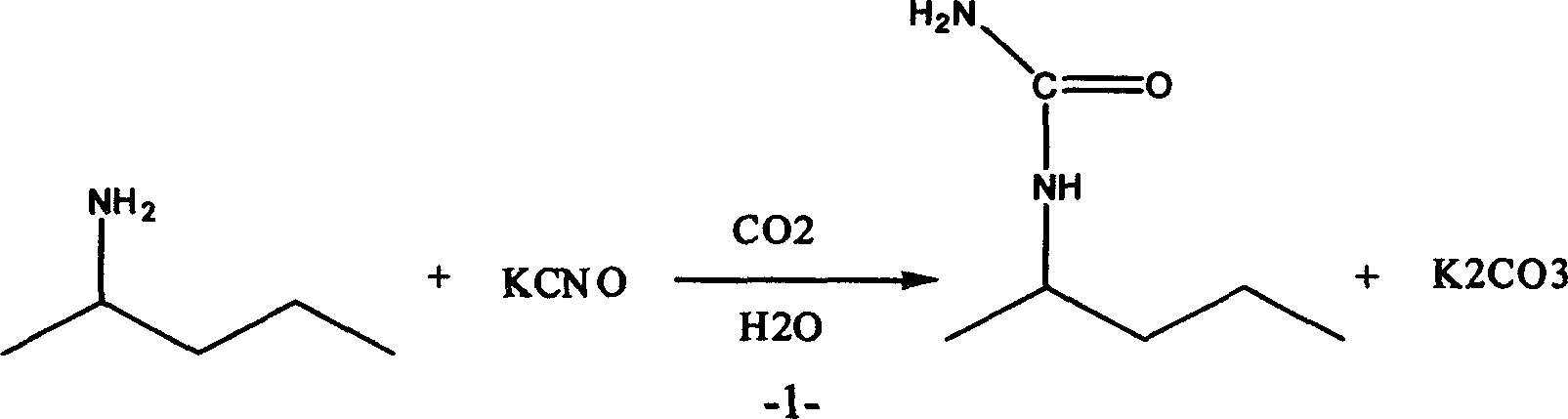

A technology for sec-butyl urea and sec-butyl amine, which is applied in the field of synthesizing sec-butyl urea by a CO2 catalytic method, can solve the problems of low market value and high cost of potassium sulfate, and achieve the effects of high market value, simple method and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dilute 8.2g of sec-butylamine with 45ml of water and put it in a four-necked flask, weigh 8.1g of potassium cyanate and dissolve it in 20ml of water, add it to the four-necked flask, stir and mix well. Infuse CO under normal pressure 2 gas, maintained at 30°C for 4 hours. Evaporate water and excess sec-butylamine, add 50ml of ethanol, filter while hot to obtain 4.5g of by-product potassium carbonate, evaporate and concentrate the filtrate to obtain 7.6g of product sec-butylurea, and the conversion rate per pass is 65.2%.

Embodiment 2

[0023] Dilute 7.3g of sec-butylamine with 20ml of water and put it in a four-necked flask, weigh 8.1g of potassium cyanate and dissolve it in 20ml of water, add it to the four-necked flask, stir and mix well. Infuse CO under normal pressure 2 gas, maintained at 55°C for 6 hours. Evaporate water and excess sec-butylamine, add 50ml of ethanol, filter while hot to obtain 3.8g of by-product potassium carbonate, and evaporate and concentrate the filtrate to obtain 6g of product sec-butylurea, with a single-pass conversion rate of 51.7%.

Embodiment 3

[0025] Dilute 8.2g of sec-butylamine with 30ml of water and put it in a four-necked flask, weigh 8.1g of potassium cyanate and dissolve it in 20ml of water, add it to the four-necked flask, stir and mix well. Inject CO at 10 atmospheres 2 gas, maintained at 60°C for 3 hours. The water and excess sec-butylamine were distilled off, 50 ml of methanol was added, and 5.6 g of by-product potassium carbonate was obtained by filtration while hot, and the filtrate was evaporated and concentrated to obtain 9.63 g of the product sec-butylurea, with a one-pass conversion rate of 83.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com