Automatic supply device for screw belt

A technology of automatic supply of screw straps, applied to screwdrivers, nailing tools, wrench, etc., can solve the problems of inaccurate locking position of screws, inaccurate displacement of screw straps, increased transmission gap, etc., and achieve the improvement of practical value , accurate locking, and the effect of reducing transmission error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

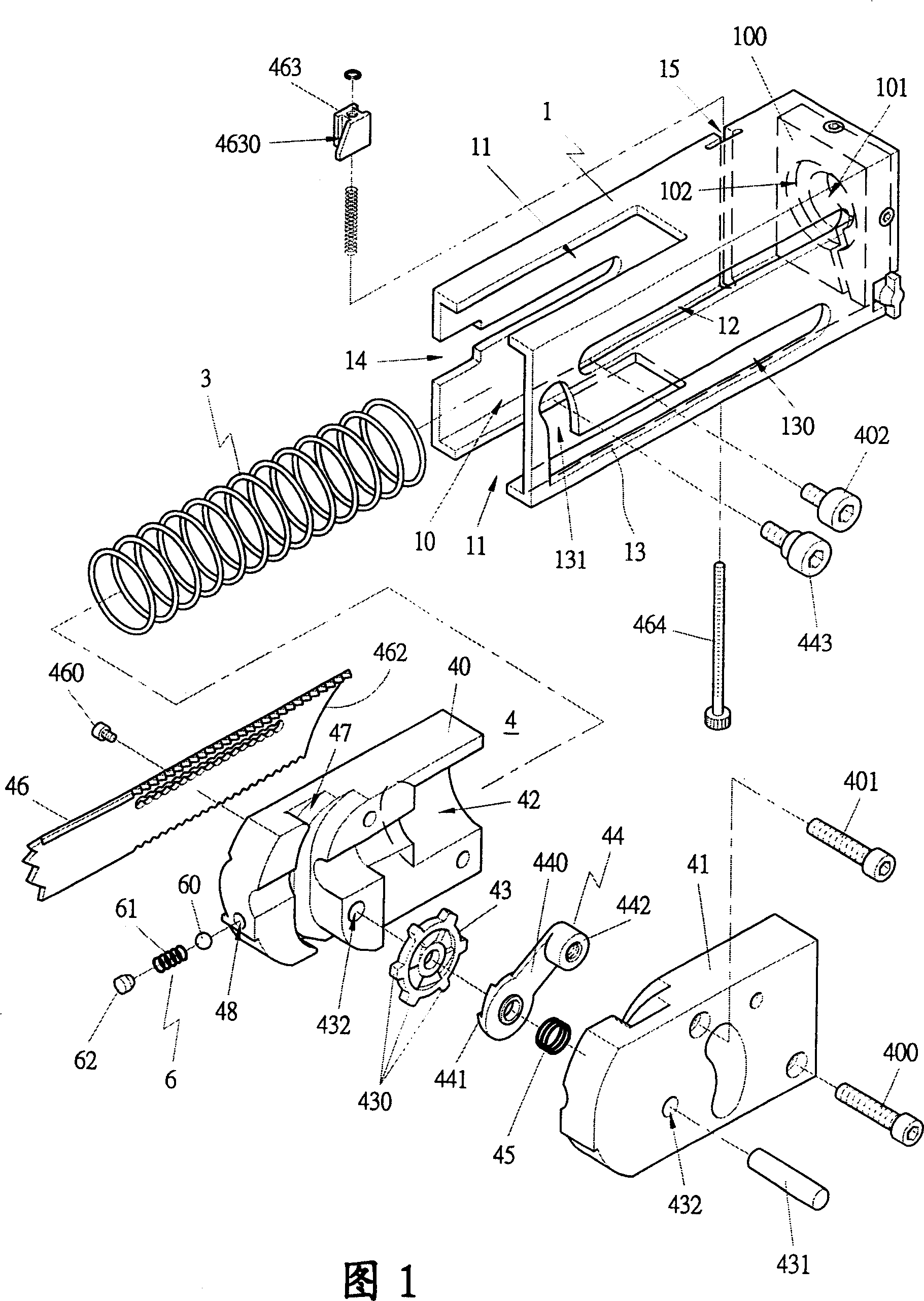

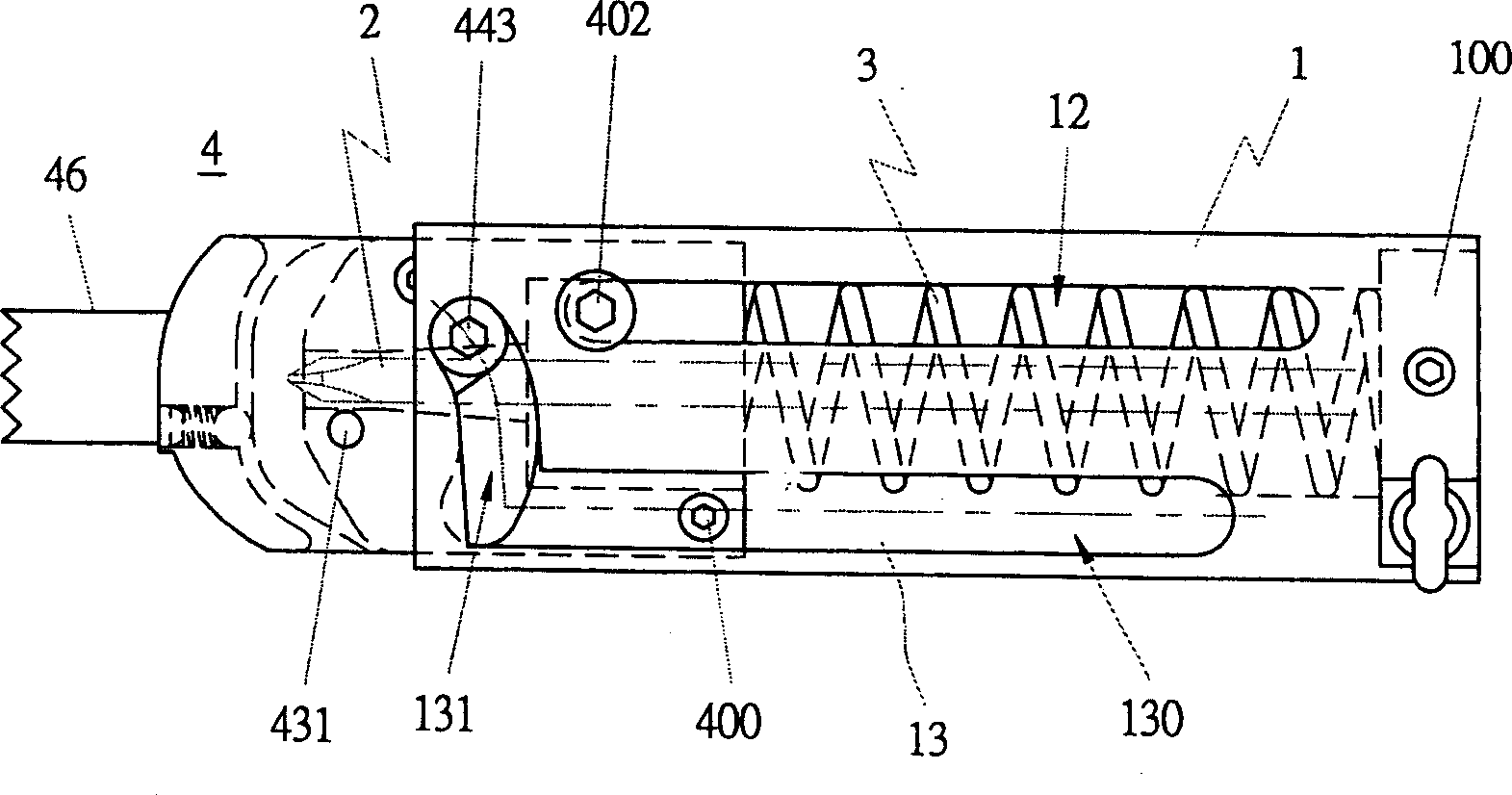

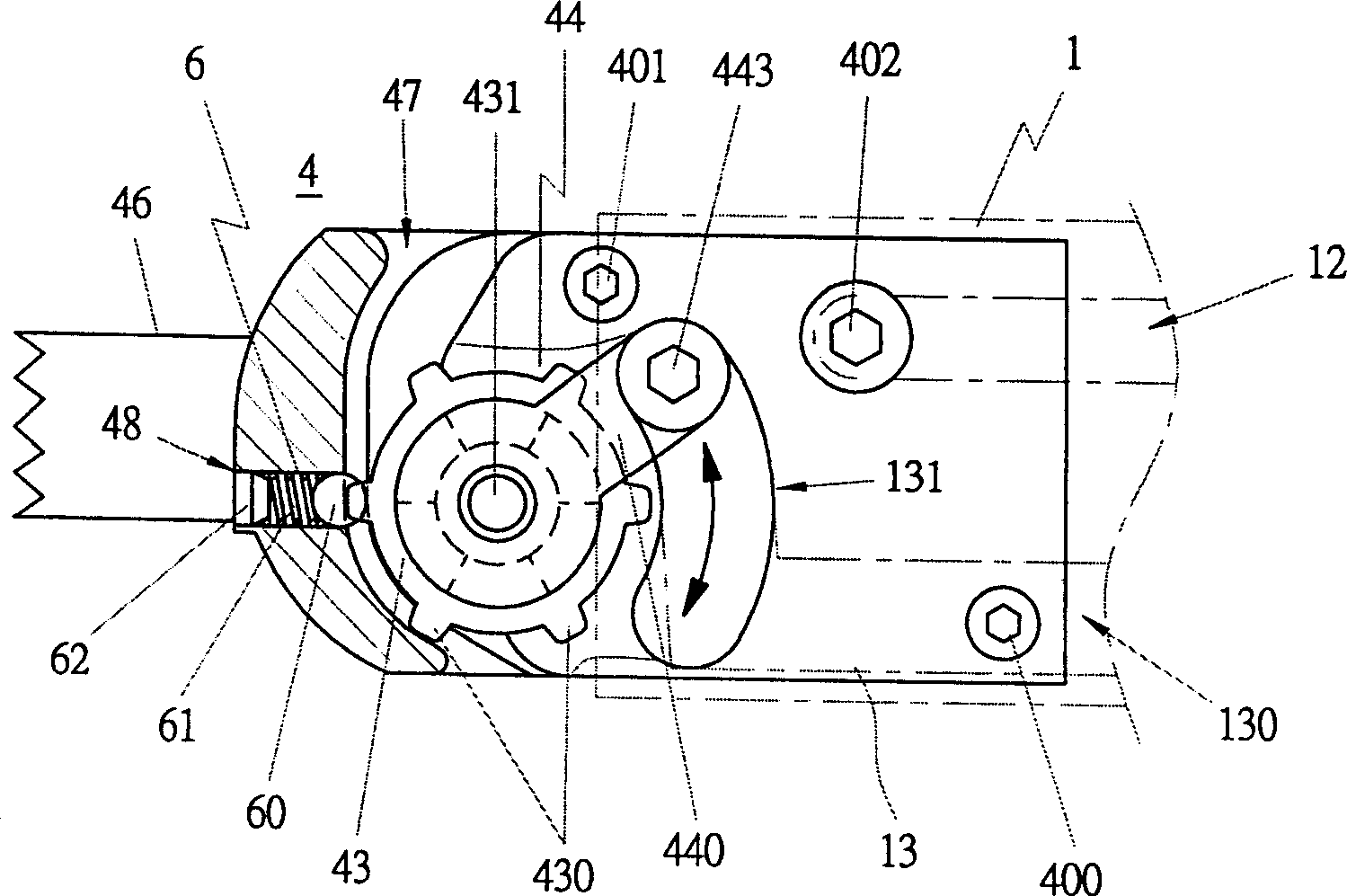

[0032] Figure 1, figure 2 , image 3 As shown, the present invention includes a body 1 , an elastic element 3 and a sliding block 4 .

[0033] The main body 1 is provided with a hollow groove 10 for the elastic element 3 and the sliding block 4 to be disposed, and a through hole 101 is provided on the rear wall 100 of the hollow groove 10 for a locking tool (bit) 2 to pass through to lock the screw. The rear wall of the hollow groove 10 is provided with an accommodating groove 102 for accommodating the elastic element 3 , so that one end of the elastic element 3 can be positioned against the top. The upper and lower walls of the body 1 are provided with slots 11 for the screw band 5 to facilitate the movement of the screw band 5 . The side wall of the main body 1 is provided with an orientation hole 12 and a driving hole 13 which is an elongated hole. The driving hole 13 has an elongated hole 130 and an arc-shaped hole 131 disposed at a front end of the elongated hole 130 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com