Hot extruding mould for gear shaping sheet heat radiator aluminium profile

A technology of hot extrusion die and radiator, which is applied in the field of hot extrusion die and hot extrusion die for tooth-shaping radiator aluminum profiles, which can solve the problems of high die pressure and achieve the effects of reducing burden, processing and aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

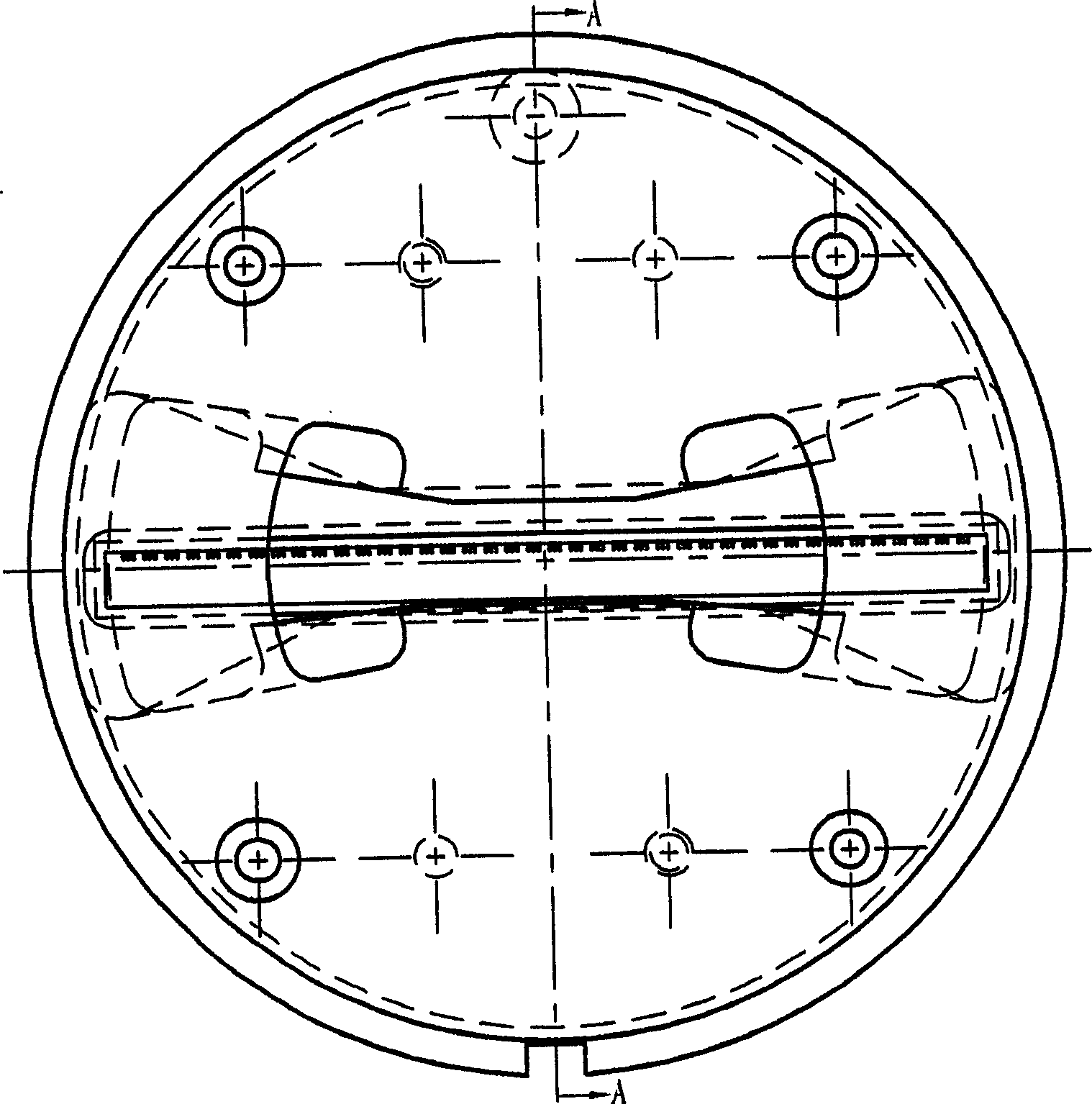

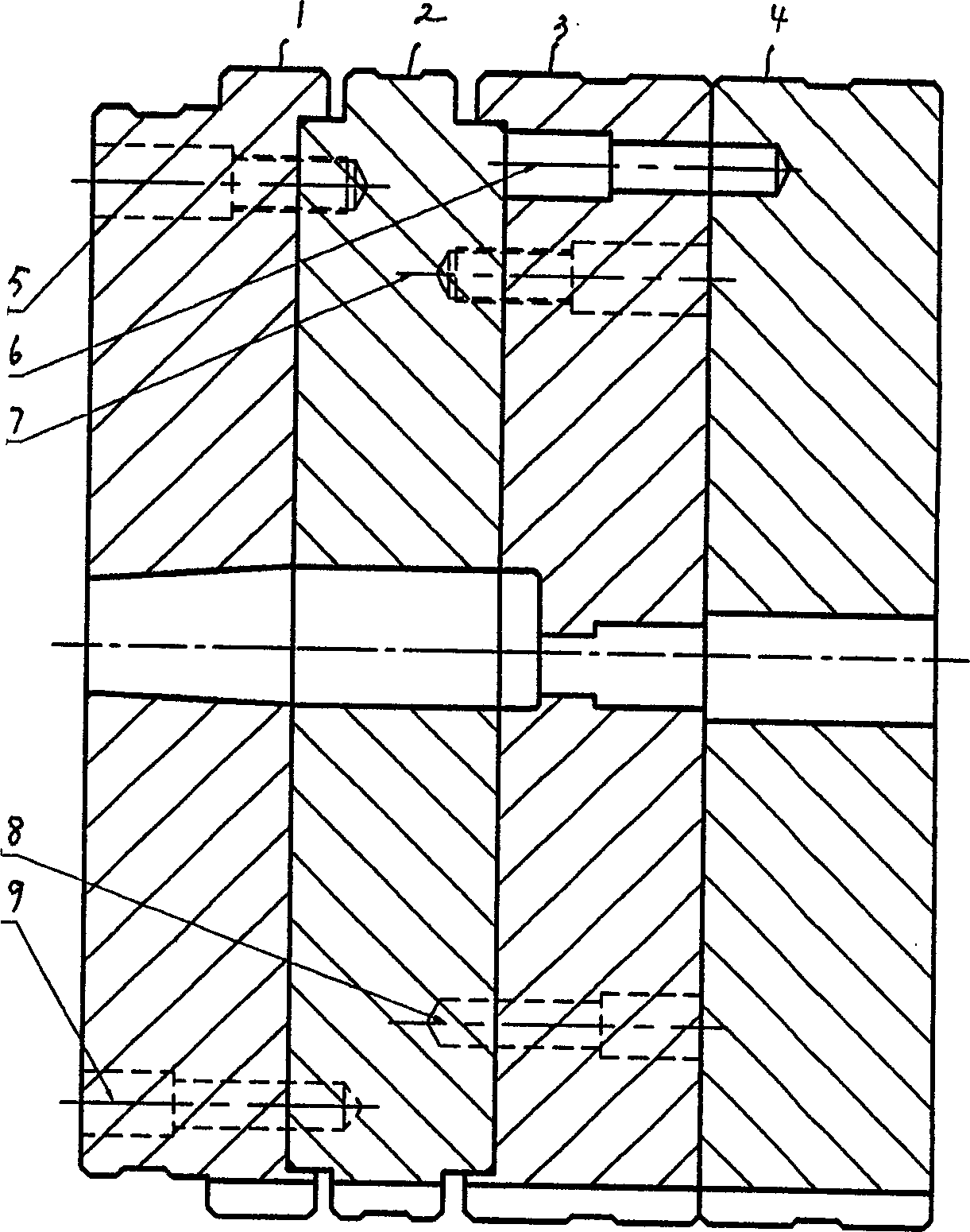

[0027] see figure 1 , 2 , The hot extrusion die for the aluminum profile of the spline fin radiator of the present invention is formed by superimposing the front deflector 1, the deflector 2, the die surface 3 and the die pad 4 sequentially from front to back. The front deflector 1 is connected with the deflector 2 with screws 5 and pins 9, the deflector 2 is connected with the mold surface 3 with screws 7 and pins 8, and the mold surface 3 is connected with the mold pad 4 with pins 6,

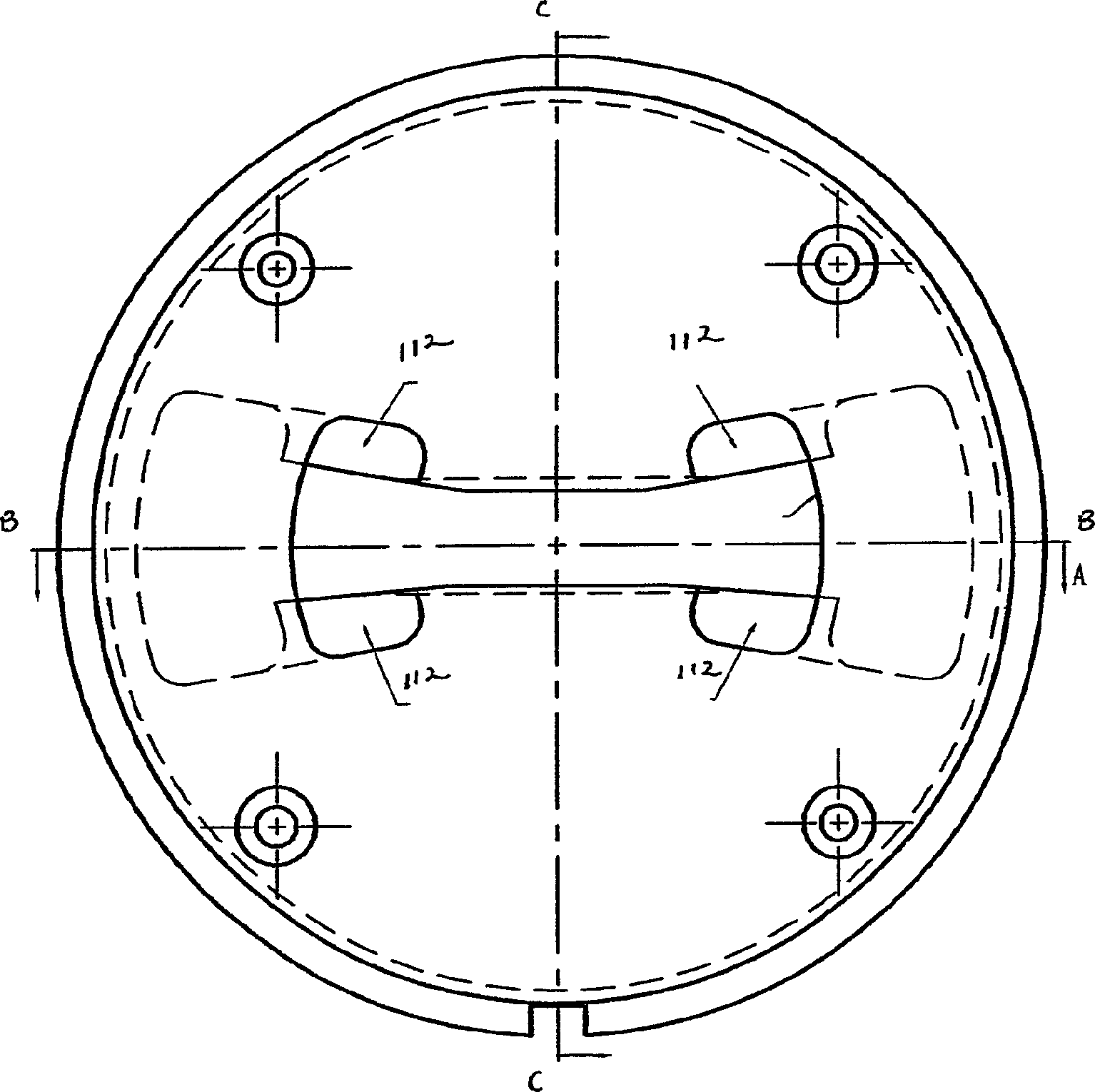

[0028] see image 3 , 4, 5, the front deflector 1, the center of the diversion opening 11 is a conical diversion opening 111, and the two sides are oblique push type expansion diversion openings 112.

[0029] see Image 6 , 7 , the deflector 2, the feed end of the diversion port 21 is an expanded diversion port 211, and the discharge end is a direct guide diversion port 212.

[0030] see Figure 8 , 9 , the shape of the diversion pit 31 at the feed end of the die surface 3 is consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com