Process for producing dried fish

A manufacturing method and technology of dried fish, applied in the preservation of meat/fish, dry preservation of meat/fish, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Small-sized frozen skipjack was thawed (the weight after thawing was 1.8 kg), and the head, viscera, etc. were removed, and boiled to obtain boiled fish. It was left to cool at normal temperature in order to obtain the state which it disassembled manually. After the fish body temperature is cooled to below 50°C, the meat part is carefully disassembled manually so that it is 5-15 cm long and the muscle septum is exposed. At this time, in order to make the muscle septum easily exposed, the fish body temperature of the boiled fish is lowered to below 30°C and quickly disassembled. At this time, among the disassembled meat parts, the meat part with a length of 5 to 15 cm accounted for 37% by weight.

[0043] Then, the boiled fish disassembled in this way is filled in a drying cage with an appropriate amount for drying, and is dried in a drying warehouse by smoking. At this point, at the end of the first pass, it was dried to an average moisture of 32%.

[0044] Finally, ...

Embodiment 2

[0052] About 5 kg of boiled fish obtained by dismantling similarly to Example 1, 300 g of boiled juice (Brix5.8) obtained at the time of boiling was sprayed on the surface, and it adhered. Then, carry out drying with the same method among the embodiment 1. Dried bonito of the present invention (hereinafter referred to as product 2 of the present invention) was obtained.

[0053] Sensory evaluation and analysis of aroma components were carried out in the same manner as in Example 1. The results are shown in Table 2 below. It should be noted that, considering the convenience of comparative comparison, the table also shows the results of product 1 of the present invention and reference product 1 in Example 1 at the same time.

[0054] Reference substance 1

[0055] As shown in the table, it can be seen that the smoky taste and the grilled taste of the present invention product 2 are further enhanced in a well-balanced manner compared with the present invention produ...

Embodiment 3

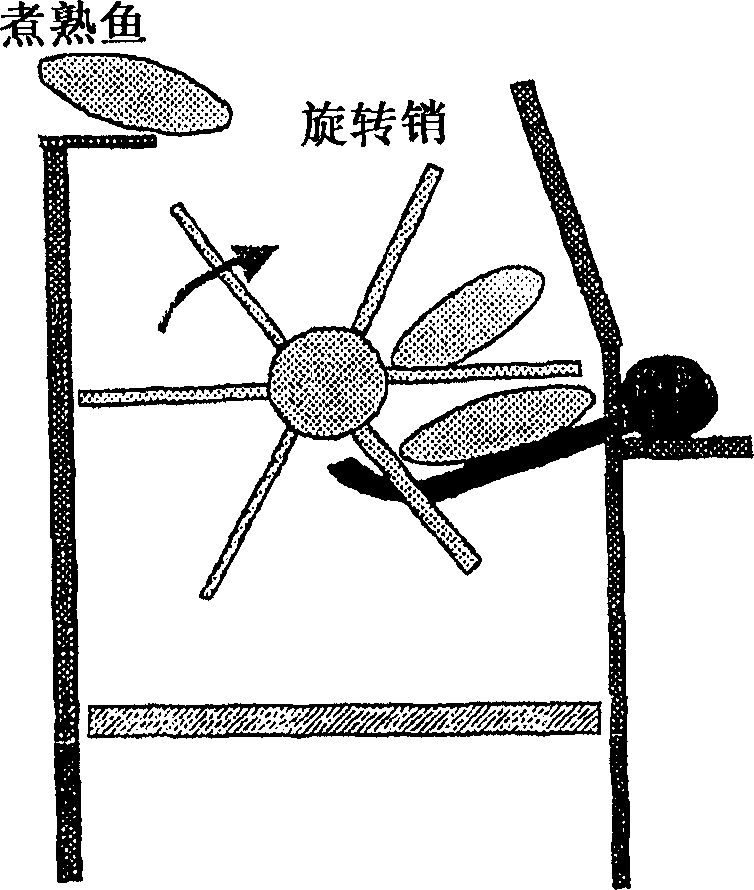

[0057] Next, the dismantling apparatus and the manufacturing method of dismantled meat slices according to the present invention will be described with reference to the drawings.

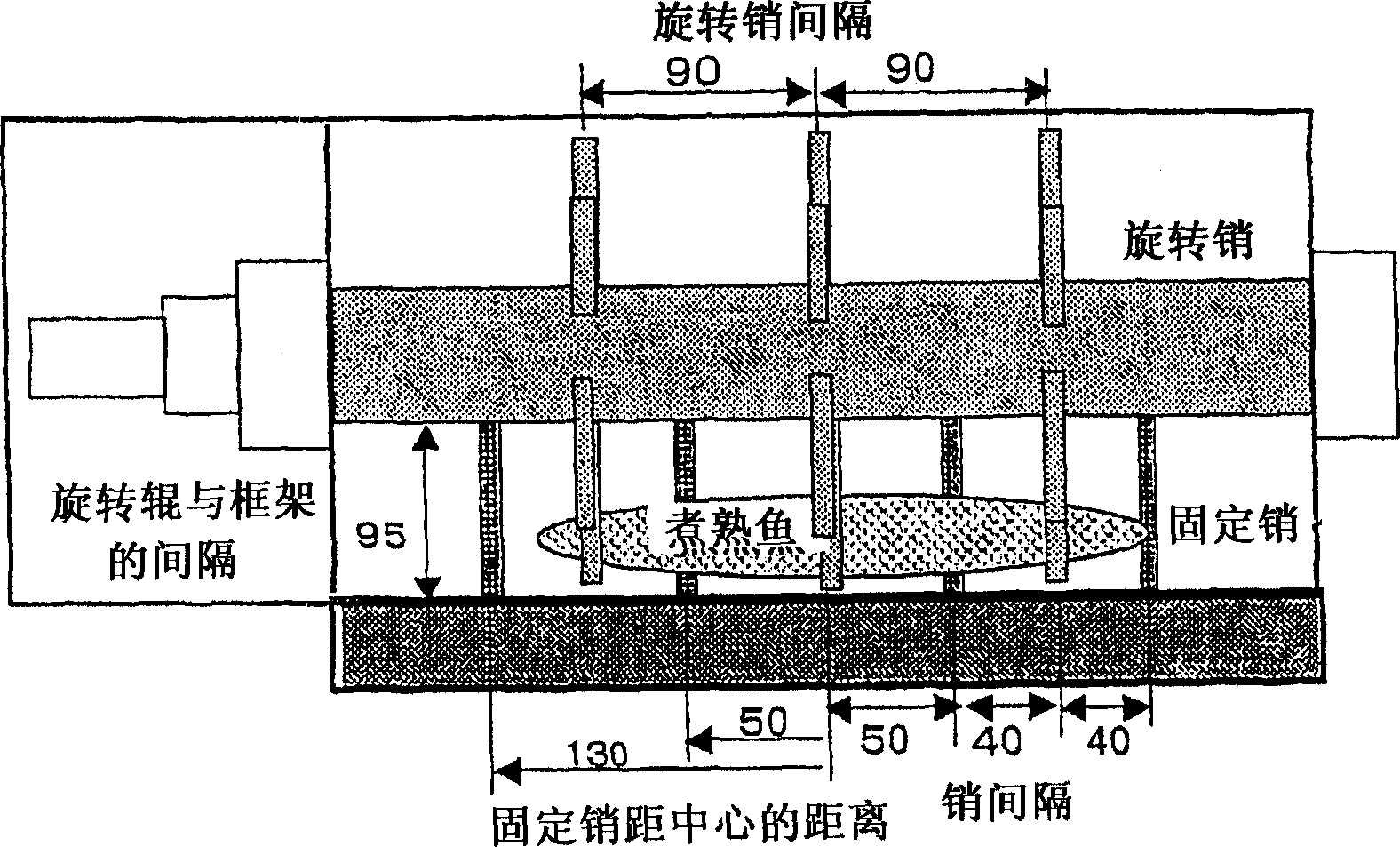

[0058] figure 1 It is a plan explanatory view of an example of the dismantling device of boiled fish of the present invention, and, figure 2 is its side view.

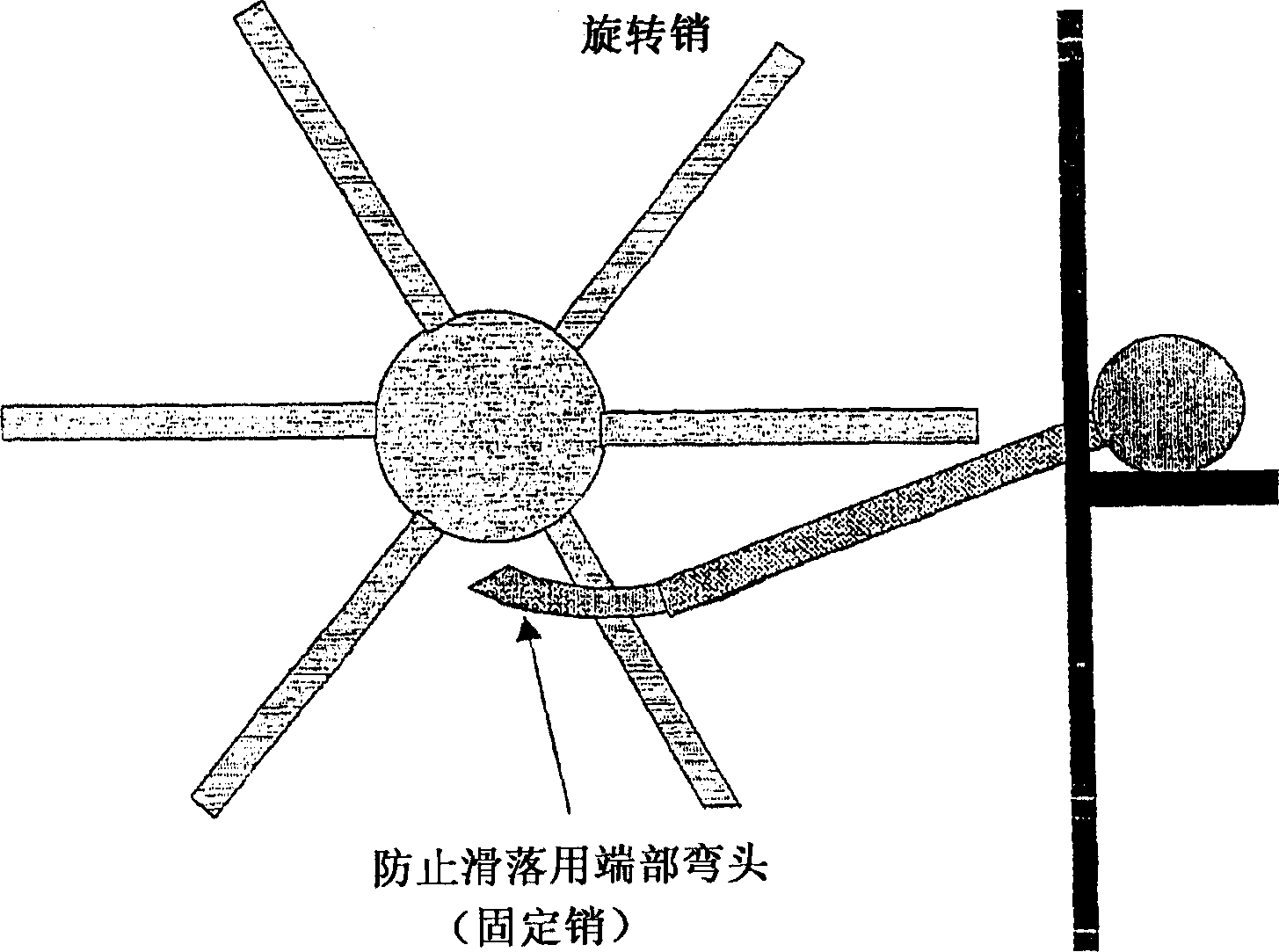

[0059] Such as figure 1 and figure 2 As shown, the dismantling device of the present invention is on the basic platform, so that the rotating pin and the fixed pin installed on the rotating roller are designed opposite to each other, and the rotating roller is driven and rotated by a motor. On the rotating roll, 6 pins (total 18 pins) were provided at equal intervals of 90 mm along the roll axis direction and at equal angles of 60 degrees in the roll circumferential direction on the rotating roll. The length of the fixing pin is 120mm, and four pieces are installed at a distance of 50mm and 130mm from the center to the left and right, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com