High-speed knitter

一种高速编织机、机架的技术,应用在编织物、纺织品和造纸等方向,能够解决降低高速编织机耐用性、增加装配调整的难度、装配调整难度大等问题,达到降低加工成本和装配难度、降低装配难度、结构紧凑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

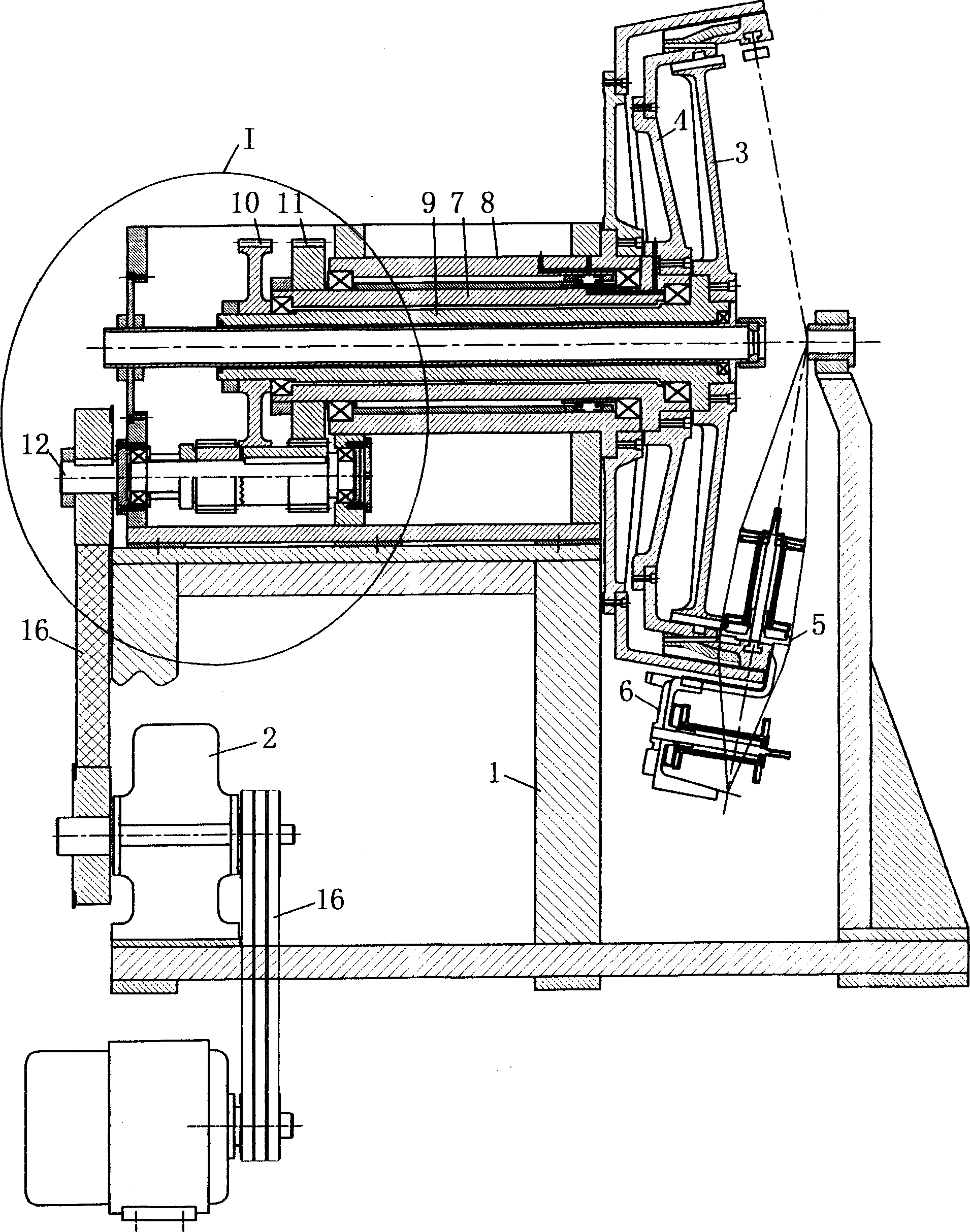

[0010] see Figure 1 to Figure 4 , The high-speed braiding machine includes a frame 1, a prime mover 2, an inner spindle drive disc 3 and an outer spindle drive disc 4. The prime mover 2 can usually adopt an electric motor. The inner ingot driving disc 3 and the outer ingot driving disc 4 respectively drive a plurality of inner ingot supports 5 and outer ingot supports 6 to rotate at high speed (in order to make the view clear, figure 1 Draw only one inner and one outer spindle holder). Outer ingot driving disc rotating shaft 7 is sleeved in an empty shaft sleeve 8 fixed with the frame. The inner ingot driving disc rotating shaft 9 is sleeved in the outer ingot driving disc rotating shaft 7 again. The inner ingot driving disc rotating shaft 9 is also a hollow shaft, which can be used for cables to run through it. Cylindrical gears 10, 11 are respectively installed on the ends of the inner ingot driving disc rotating shaft 9 and the outer ingot driving disc rotating shaft 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com