Heald shaft for a weaving machine

A technology of heald frames and looms, which is applied in textiles, healds, textiles, and papermaking, and can solve problems such as limiting the working speed of looms and increasing the weight of heald frame boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

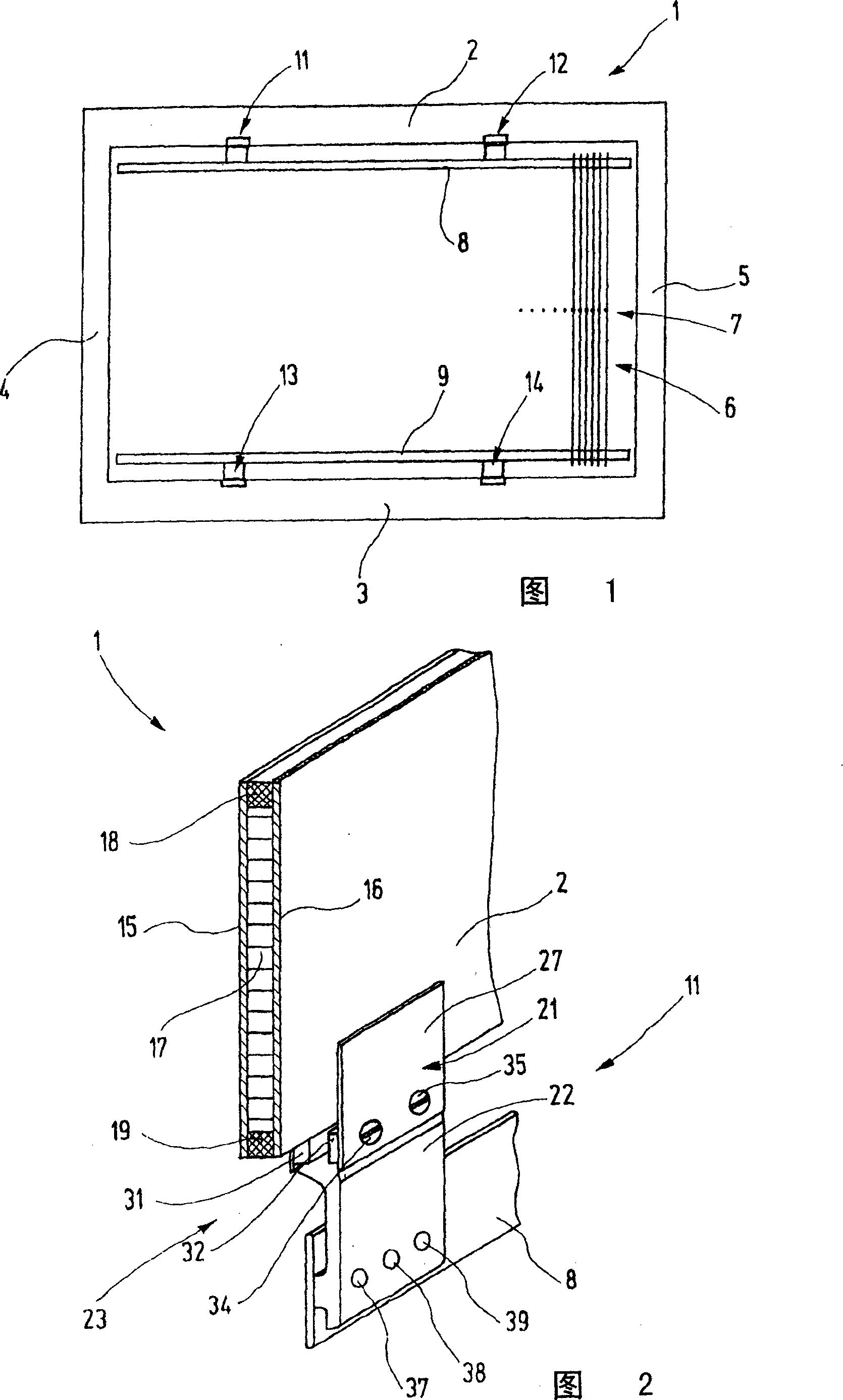

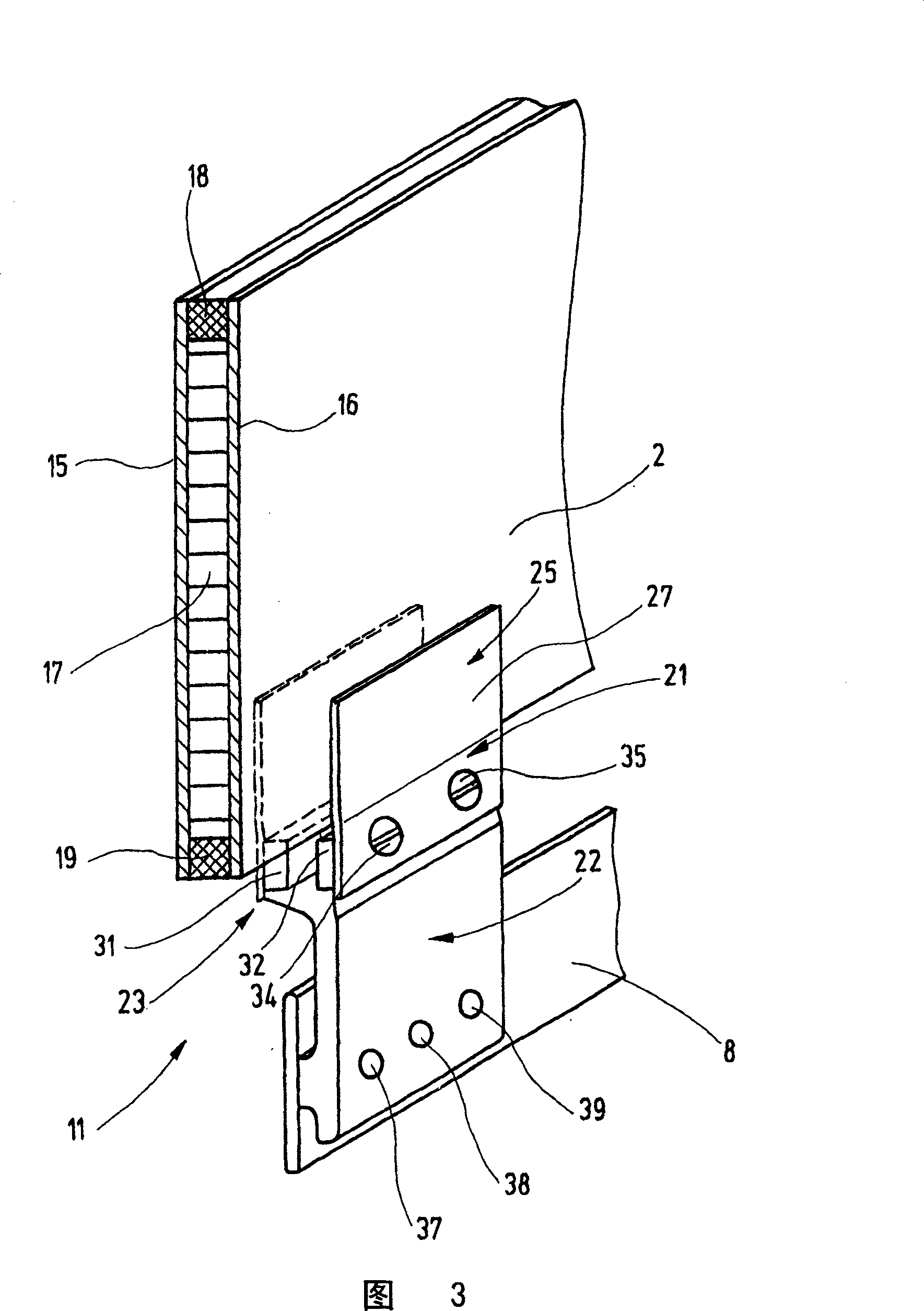

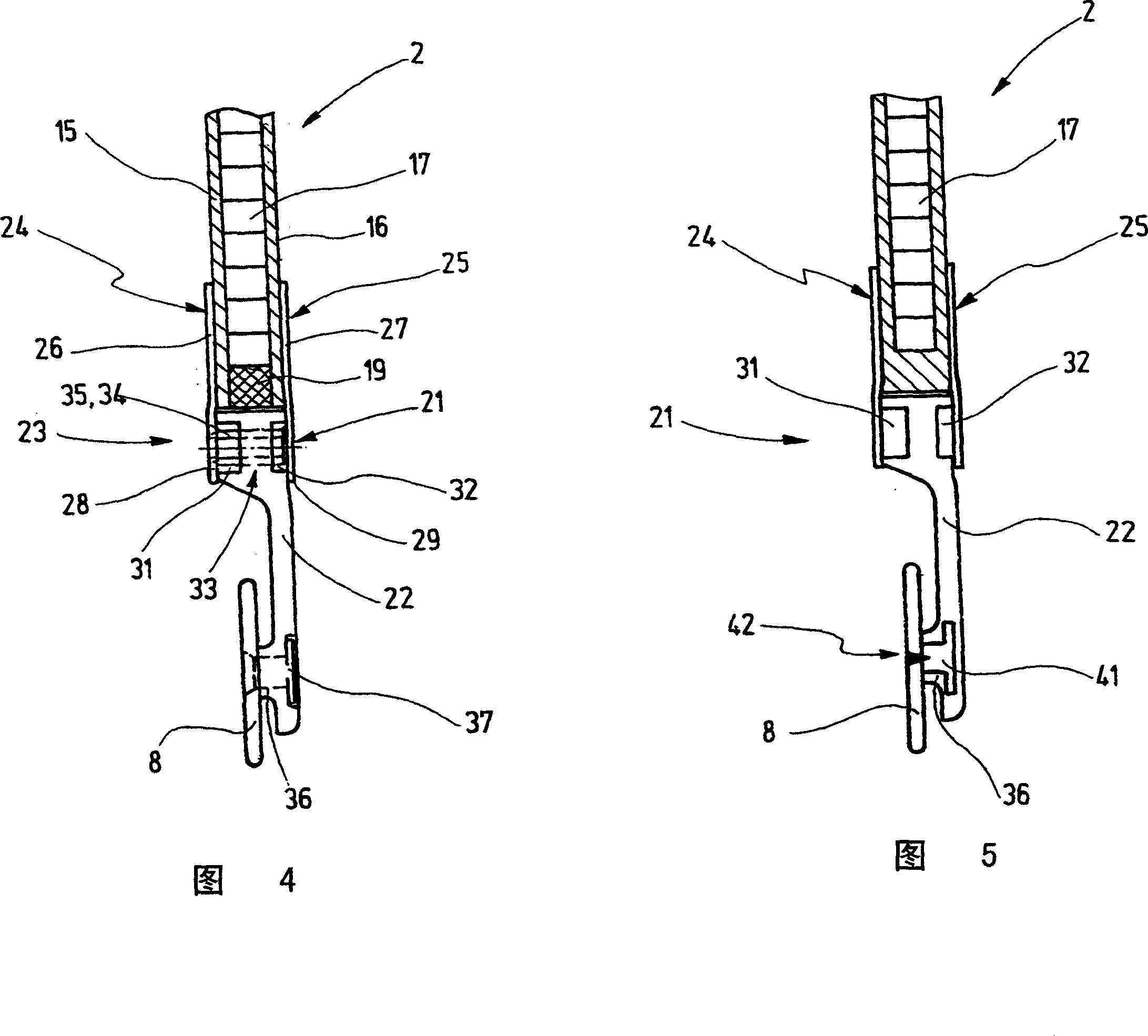

[0028]FIG. 1 shows a heald frame 1 having an upper, generally horizontally arranged heald frame plate 2 and a heald frame plate 3 fastened parallel thereto at a distance. The heald shaft plates 2 , 3 are connected to one another at their ends by side supports 4 , 5 so that together with the heald shaft plates 2 , 3 they form a rectangular frame. A plurality of healds 6 arranged parallel to one another are arranged in the frame and are each provided with a thread guide eye 7 for guiding a warp thread. The healds 6 arranged parallel to the side supports 4 , 5 each have a heald lug at their upper and lower ends, with which they are fastened to a heald rod 8 , 9 . The heald rods 8 , 9 extend parallel to the respective adjacent heald frame plates 2 , 3 and are held at a distance therefrom. Connecting devices 11 , 12 , 13 , 14 are used for this purpose, and they respectively form a releasable connection between each heald frame plate 2 , 3 and the heald rods 8 , 9 assigned to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com