Method for purifying spirit liquor by nano-porcelain small balls

A technology of nano-ceramics and small balls, applied in the field of liquor purification, to achieve the effect of low market price, low cost, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

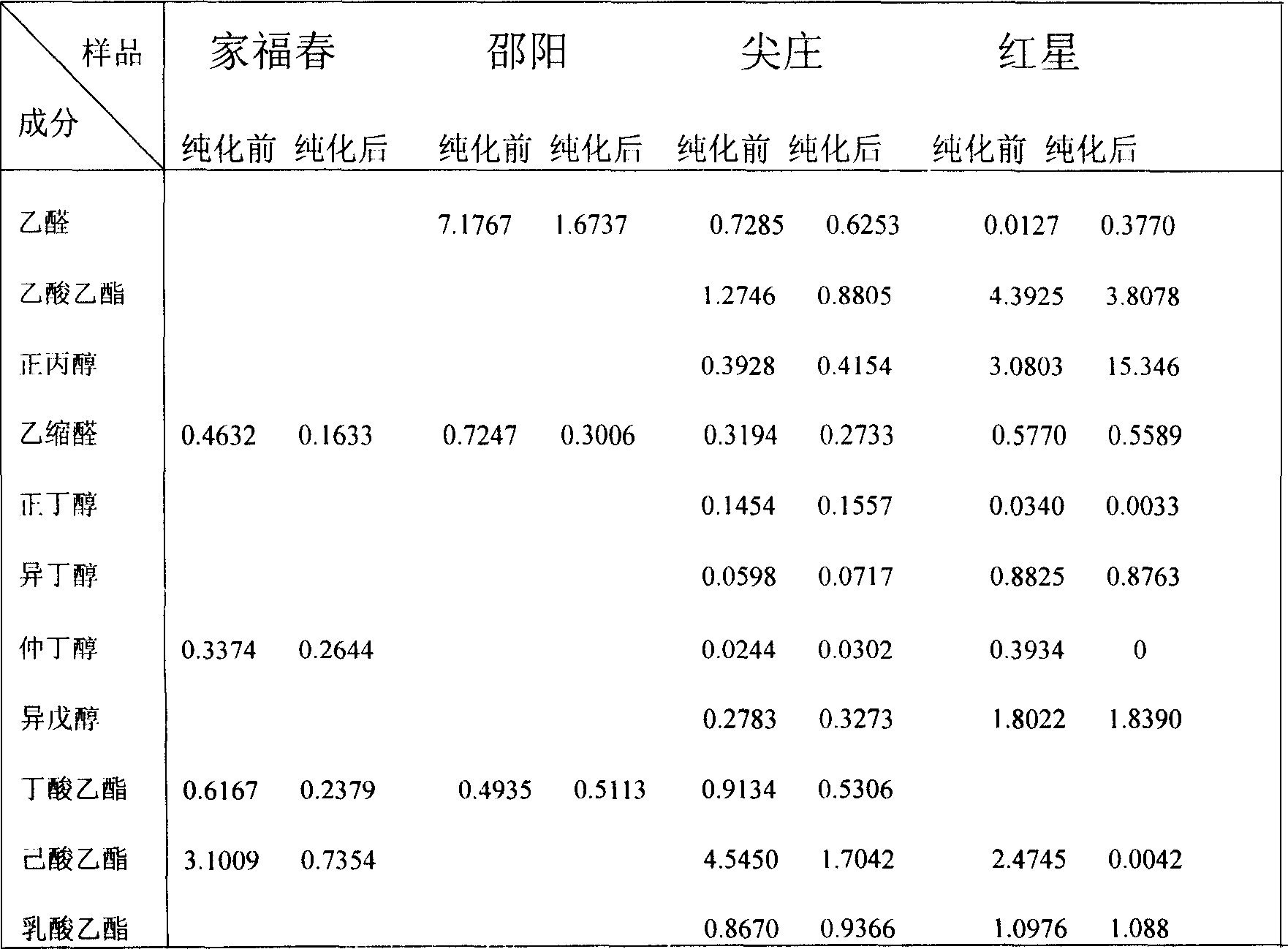

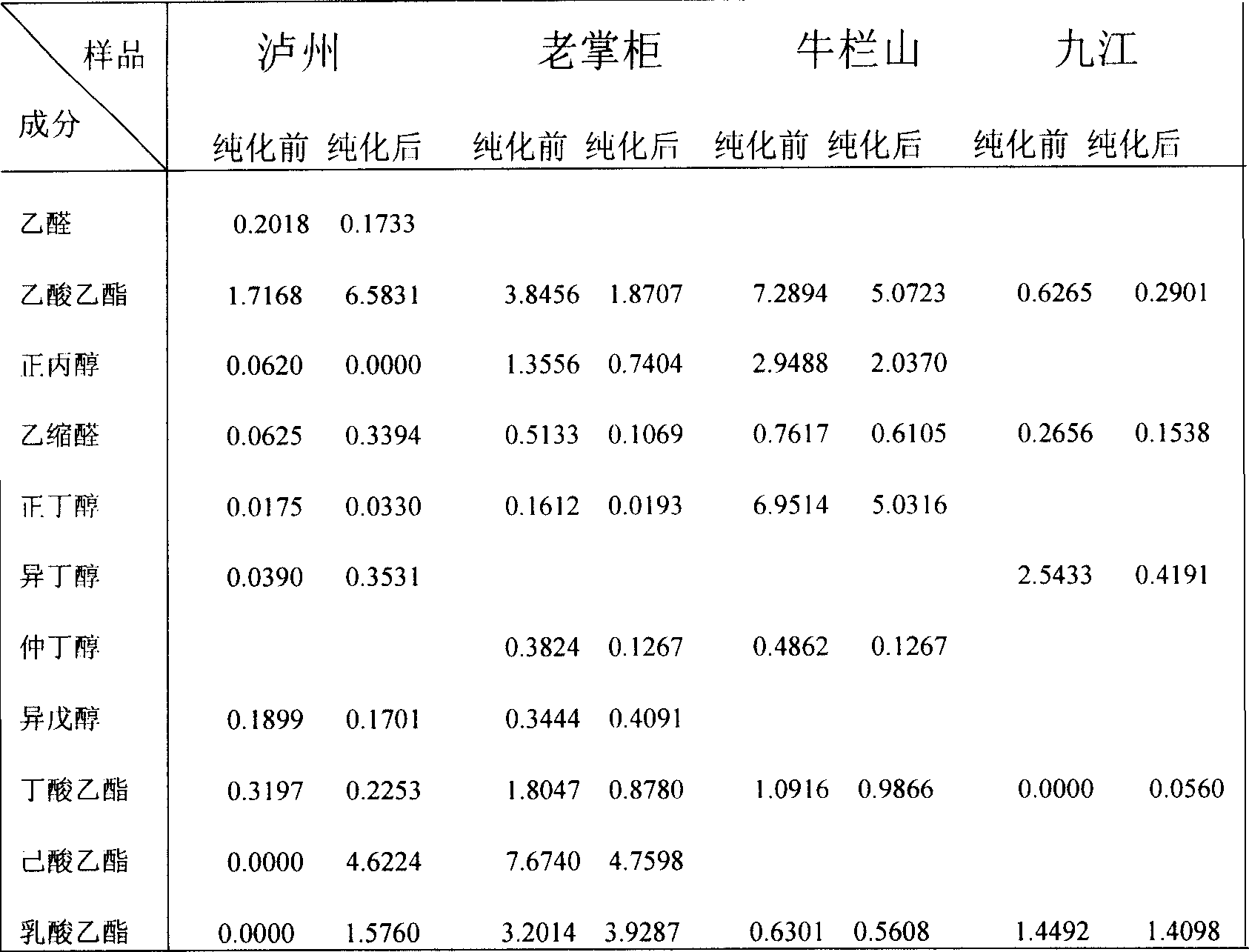

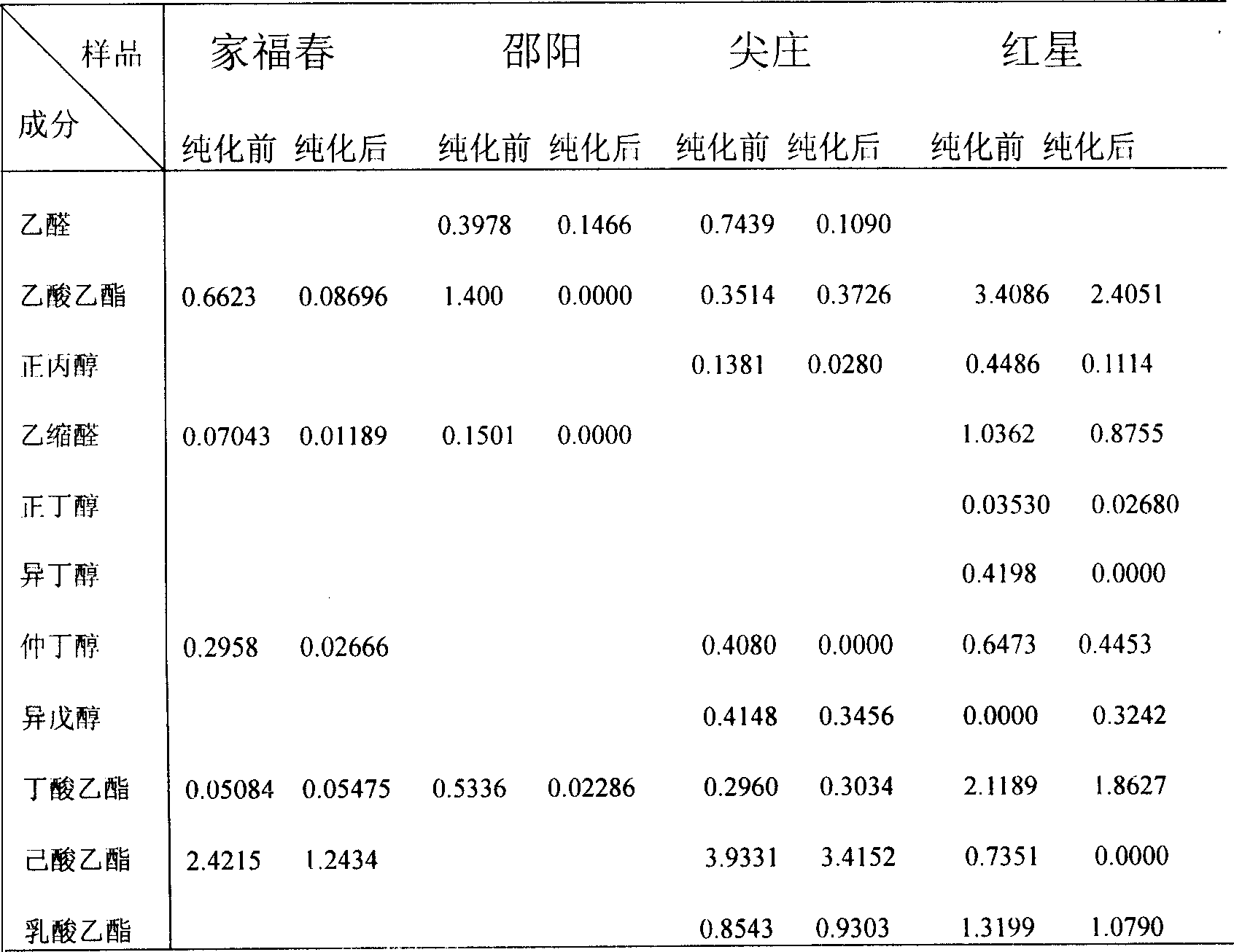

Examples

Embodiment 1

[0016] Add 20g of nano-ceramic balls produced by Inner Mongolia Xinyuan Ceramics Factory, with a diameter of 2 to 3mm, used for drinking water treatment, into 100g of "Shaoyang Laojiu" liquor, and let it stand for 24 hours at a temperature of 30°C. Then filter out the nano-ceramic balls to obtain purified liquor.

Embodiment 2

[0018] Add 100g of nano-ceramic balls produced by Inner Mongolia Xinyuan Ceramics Factory with a diameter of 2 to 3mm and used for drinking water treatment into 20g of "Red Star Erguo" liquor head, and let it stand for 24 hours at a temperature of 40°C. hours, and then filter out the nano-ceramic beads to obtain purified liquor.

Embodiment 3

[0020] Add 100g of nano-ceramic balls produced by Inner Mongolia Xinyuan Ceramics Factory with a diameter of 2 to 3mm and used for drinking water treatment into 2000g of Luzhou Laojiao, let it stand for 240 hours at a temperature of 30°C, and then filter Remove the nano-ceramic pellets to obtain purified liquor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com