Electromagnetic heater and electromagnetic oven with the same electromagnetic heater

A heater and induction cooker technology, applied in the field of induction cooker, can solve problems such as high cost, inability to use induction cooker heating, unrealistic and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

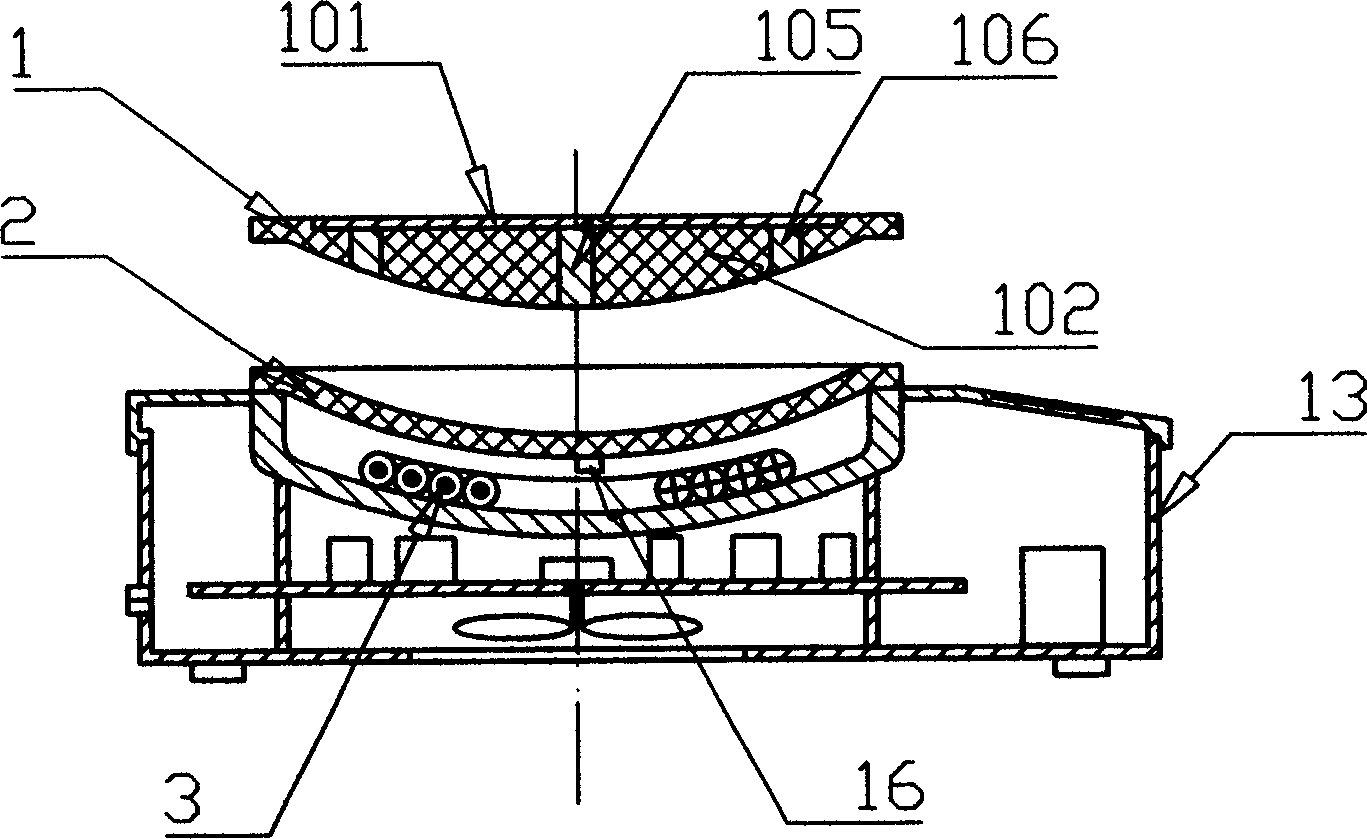

[0047] Embodiment 1, as figure 1 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 Shown, present embodiment is a kind of induction cooker with electromagnetic heater.

[0048] In this embodiment, an electromagnetic oven with an electromagnetic heater mainly consists of a housing 13, a support 4, an electromagnetic induction coil assembly 3, a magnetically permeable heat insulating panel 2, a total circuit board 6, a power conversion device 7, a cooling system 8, and a control system 9 An induction cooker composed of various parts such as protection system 10; its feature is: an electromagnetic heater 1 can also be placed on the magnetically permeable and heat-insulating surface 2 of the induction cooker, and a heat-conducting backing plate 17 can also be placed on the electromagnetic heater 1, so as to It is suitable for heating appliances with bottoms of various structural shapes, and the electromagnetic heater 1 or the heat conduction backi...

Embodiment 2

[0067] Embodiment 2, as figure 2 As shown, this embodiment is an electromagnetic oven with a concave magnetically permeable and heat-insulating panel with an electromagnetic heater.

[0068] The difference between this embodiment and embodiment 1 is:

[0069] 1. The magnetically permeable and heat-insulating panel 2 of this embodiment is made into a concave shell-shaped structure with a concave center and a circular plate-shaped periphery. Correspondingly, the electromagnetic induction coil assembly 3 must match the magnetically permeable and heat-insulating panel 2. The electromagnetic induction coil assembly 3 is made into a disc-shaped structure with a concave center. It is also possible to make the electromagnetic induction coil assembly 3 and the magnetically permeable heat insulating panel 2 into an integrated structure.

[0070] 2. What the electromagnetic induction coil assembly 3 of the present embodiment adopts is the power frequency electromagnetic induction coil...

Embodiment 3

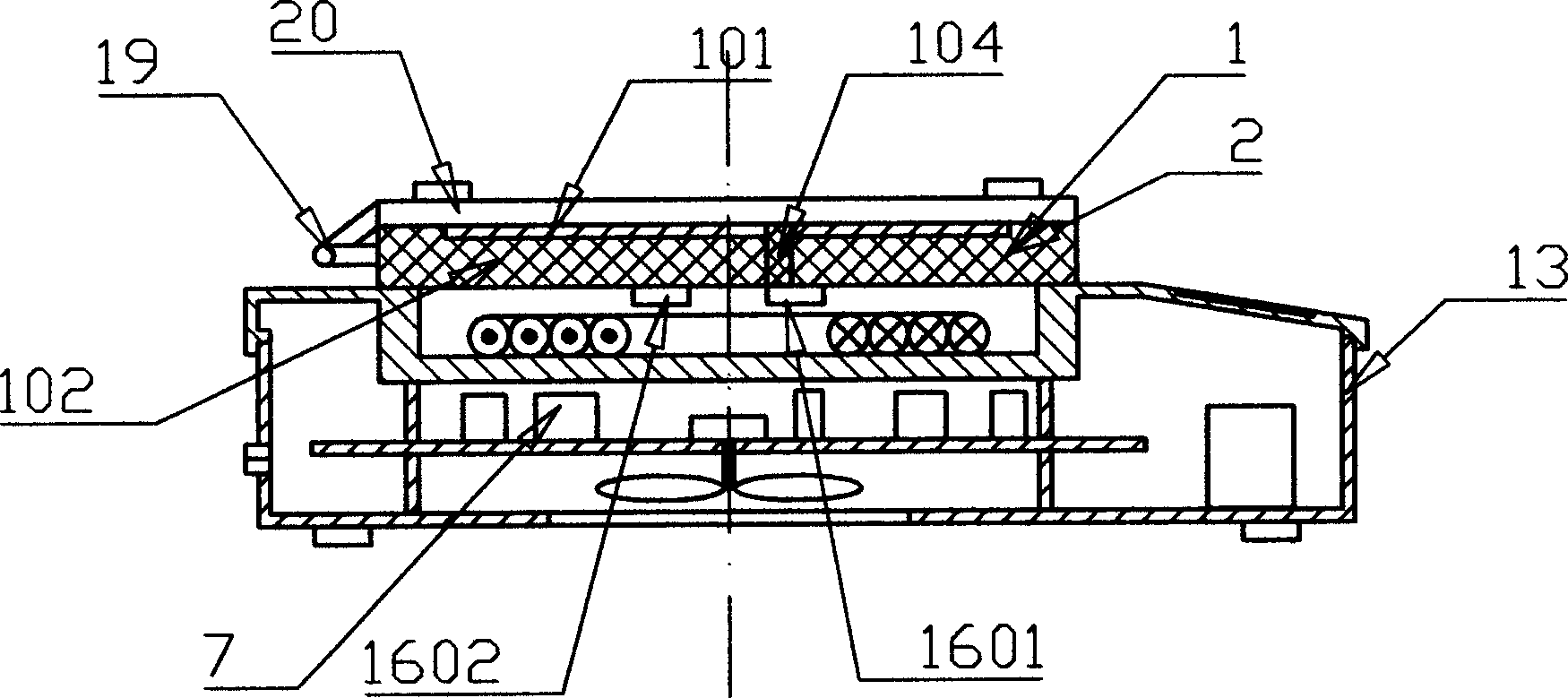

[0075] Embodiment 3, as image 3 As shown, the present embodiment is an induction cooker with a flat panel that regards the electromagnetic heater and the magnetically permeable heat insulation panel as one component.

[0076] The difference between this embodiment and embodiment 1 is:

[0077] 1. In this embodiment, the electromagnetic heater 1 and the magnetically permeable heat-insulating panel 2 are regarded as one component, the electromagnetic heater 1 , and the pot support 20 connected by a hinge connection structure 19 is placed on the electromagnetic heater 1 . The center and periphery of the lower part of the magnetizer 101 of the electromagnetic heater 1 of the present embodiment omit the ferromagnet 105 and the ferromagnet 106 of the embodiment 1, and the three pot legs on the electromagnetic heater 1 of the embodiment 1 are omitted 108 and three pot leg grooves 109.

[0078] 2. What the power conversion device 7 of this embodiment adopts is a high-frequency powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com