Detum error separating method of cylindricity instrument based on self characteristic reference

A technology of error separation and cylindricity, which is applied in the direction of instruments, measuring devices, mechanical counters/curvature measurement, etc., can solve problems such as lowering measurement accuracy, difficulty in unifying the measurement profile, inconsistent sensor characteristics, etc., and achieve the effect of improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

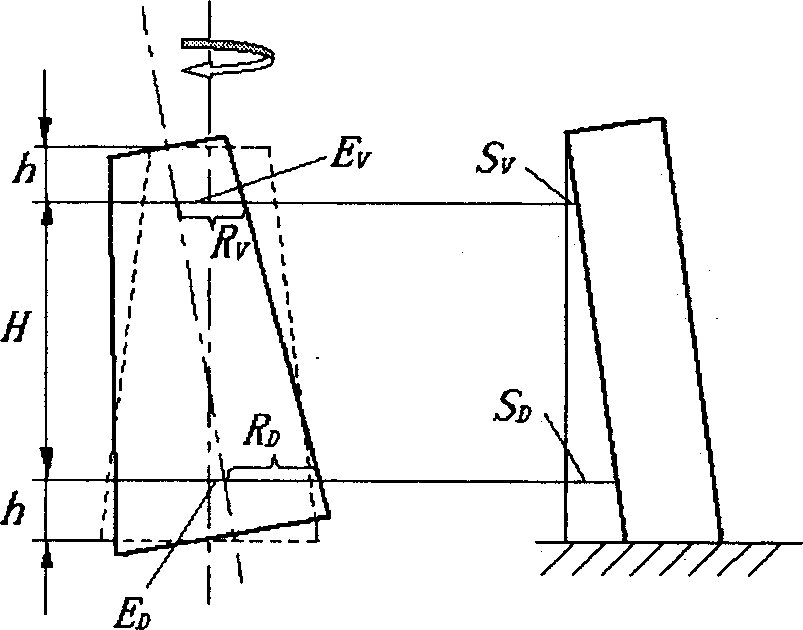

[0031] Select two measurement sections.

[0032] Select a standard cylinder of 75×300, take the number of measurement sections N=2, the number of sampling points in one week M=1024, take the measurement height H=250mm, and the distance between the sensor probe and the upper and lower end faces h=25mm.

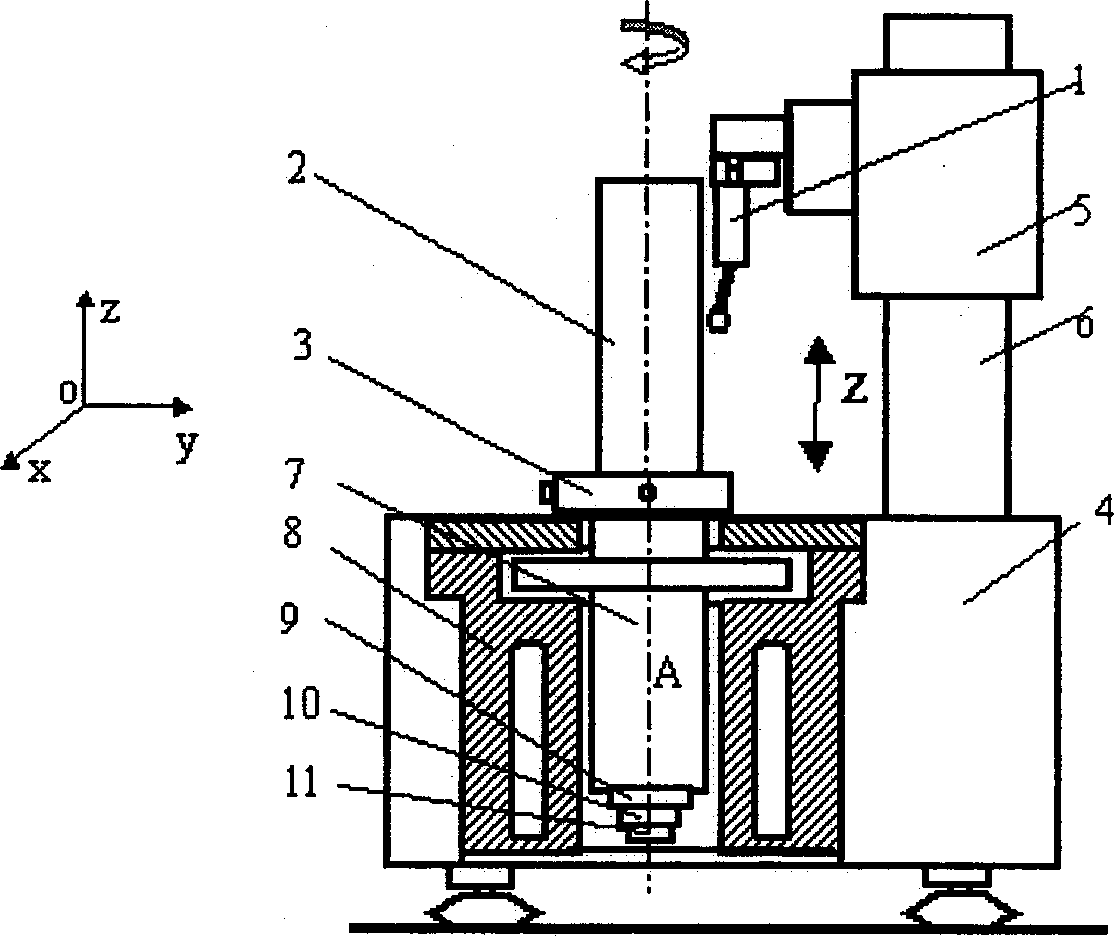

[0033] In the first test round, the test piece, that is, the standard cylinder 2, is placed forward, see image 3 , Figure 1(a). The sensor 1 moves along the guide rail, respectively measures the circular contours of the upper and lower sections, and obtains the comprehensive error value of the circular contour of the measured section. There is a measurement sequence {V 1j} and {V 2j}(j=1, 2...j...M) and has the following relational formula:

[0034] V 1j = S 1 +R 1j +E 1 ·cos(θ j -α 1 ) (1)

[0035] V 2j = S 2 +R 2j +E 2 ·cos(θ j -α 2 ) (2)

[0036] where S 1 and S 2 Respectively,...

Embodiment 2

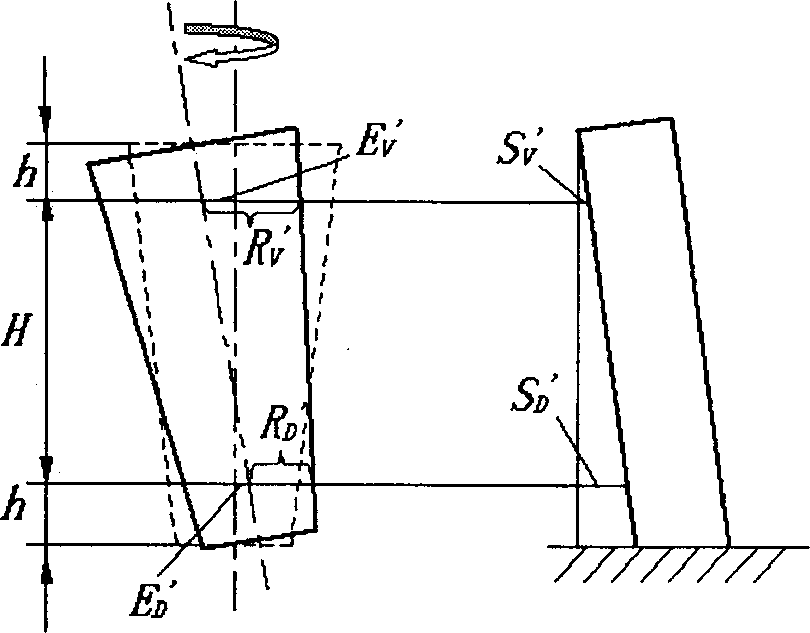

[0070] Take multiple measurement sections.

[0071] Choose a standard cylinder of 75×300, take the number of measurement sections N=30, the number of sampling points in one week M=1024, take the measurement height H=250mm, and the distance between the sensor probe and the upper and lower end faces h=25mm.

[0072] The steps are as follows:

[0073] In the first round, the standard cylinder is placed forward. see image 3 , the sensor 1 moves along the guide rail, and measures the cross-sectional circular profile of the standard cylinder at the height of 1, 2...i...N section by section, then the comprehensive error value of the measured cross-sectional circular profile is obtained, and there is a positive measurement sequence {V ij}(i=1, 2...i...N, j=1, 2...j...M), and have the following relational formula:

[0074] V 1 j ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com