Toilet flusher

A toilet flushing device and toilet flushing technology, which is applied to flushing equipment with water tanks, sanitary equipment for toilets, and indoor sanitary piping installations, etc., which can solve the problems of low concentration and low efficacy of flushing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

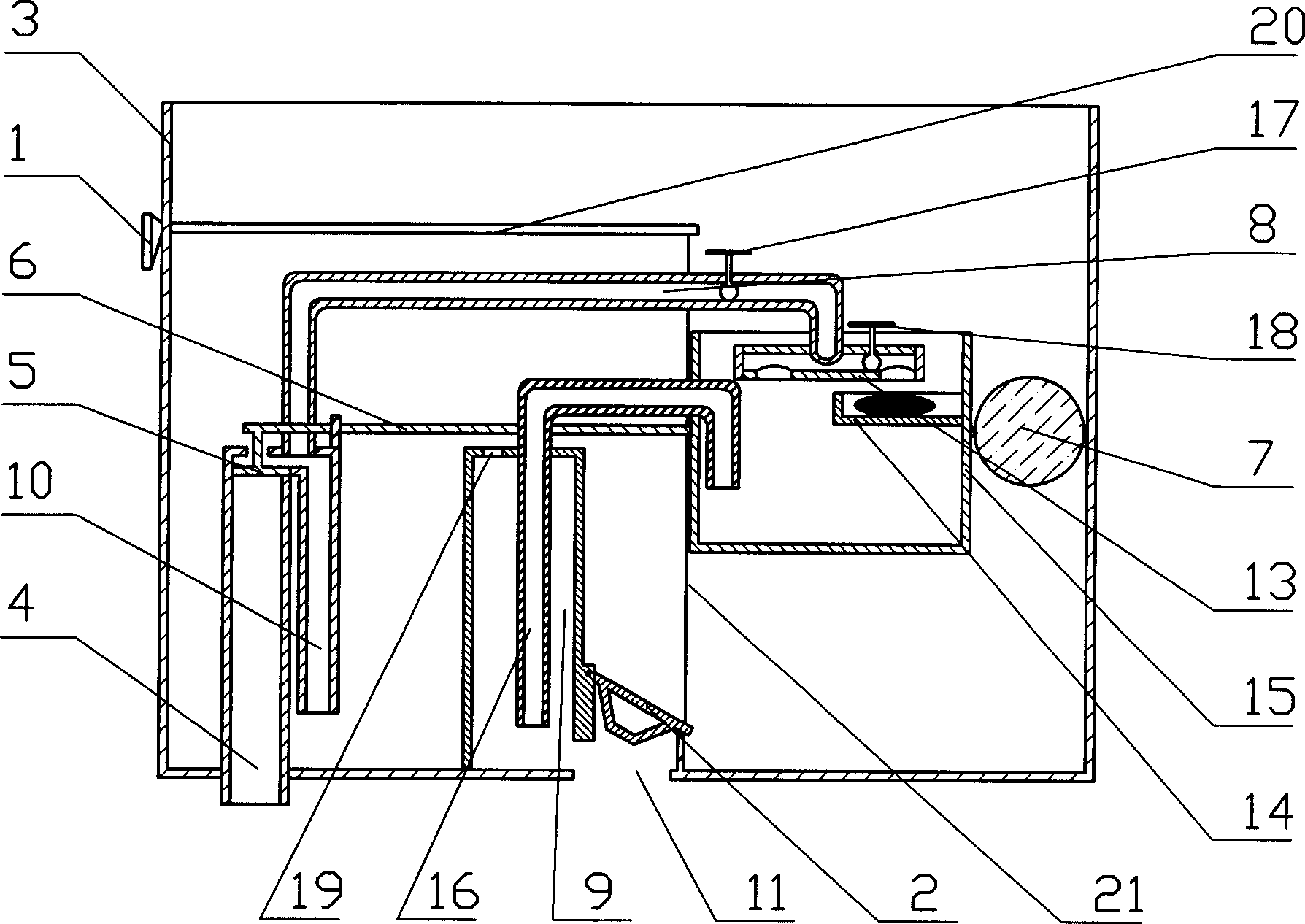

[0012] Such as figure 2 As shown, the present invention includes a water diversion head 13, a toilet flushing agent box 14, a toilet flushing device body 15, and a toilet flushing device outlet pipe 16. The present invention is installed in the common flushing water tank. The toilet flushing tank is composed of handle 1, drain gate 2, water tank body 3, water inlet pipe 4, water inlet valve 5, float rod 6, float ball 7, secondary flush water inlet pipe 8, secondary flush water pipe 9, primary The flush water inlet pipe 10 is composed of the handle 1 arranged on the upper part of the side wall of the water tank body 3, the handle 1 is connected with the drain gate 2 through a connecting rod and a rope, and the drain The gate 2 is arranged on the top of the water outlet 11 at the bottom of the water tank 3, and the upper part of the water outlet 11 of the drain gate 2 is sealed and matched to ensure that the water tank stores necessary water. The water inlet pipe 4 is arrange...

Embodiment 2

[0014] Such as image 3 As shown, the other structures of this embodiment are the same as those of Embodiment 1, except that the top of the secondary flushing pipe 9 is sealed, the outlet pipe 16 of the toilet flusher is also an inverted U-shaped elbow, and the The water outlet end of the toilet outlet pipe 16 extends approximately close to the water outlet 11 and is lower than the water inlet end. The bottom of the U-shaped elbow is approximately horizontally arranged. After a large amount of primary flushing, the secondary There is a certain negative pressure in the flushing pipeline 9, and the pressure in the toilet flusher is greater than the pressure in the secondary flushing pipeline 9, so the water dissolved in the toilet flushing agent in the toilet flusher can be quickly flushed The secret channel to the toilet tray can better play a cleaning role, so the toilet flushing agent can be effectively used, and the cleaning effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com