Dry process mechanical force and chemical modification method of superfine calcium carbonate

A mechanochemical and calcium carbonate technology, applied in dyeing low-molecular organic compound treatment, dyeing physical treatment, fibrous filler, etc., can solve the problems of high equipment investment cost and complicated process, and achieve simple structure, improved dispersion, The effect of improving flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

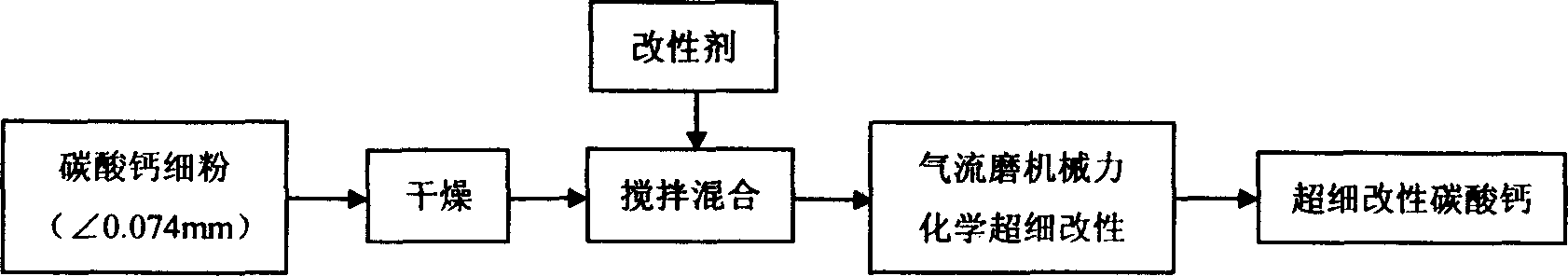

[0020] The method of dry mechanochemical ultra-fine modification of calcium carbonate includes the following steps: First, the fine calcium carbonate powder (∠0.074mm) is dehydrated in a drying oven at 100-110°C, and then the calcium carbonate and modifier are mixed with a mixer Stearic acid is evenly mixed, and the added amount of stearic acid is 0.5-5.0% of the mass of calcium carbonate, and then the mixed materials are added to the jet mill to pulverize to obtain ultra-fine modified calcium carbonate.

[0021] (1) Sample source

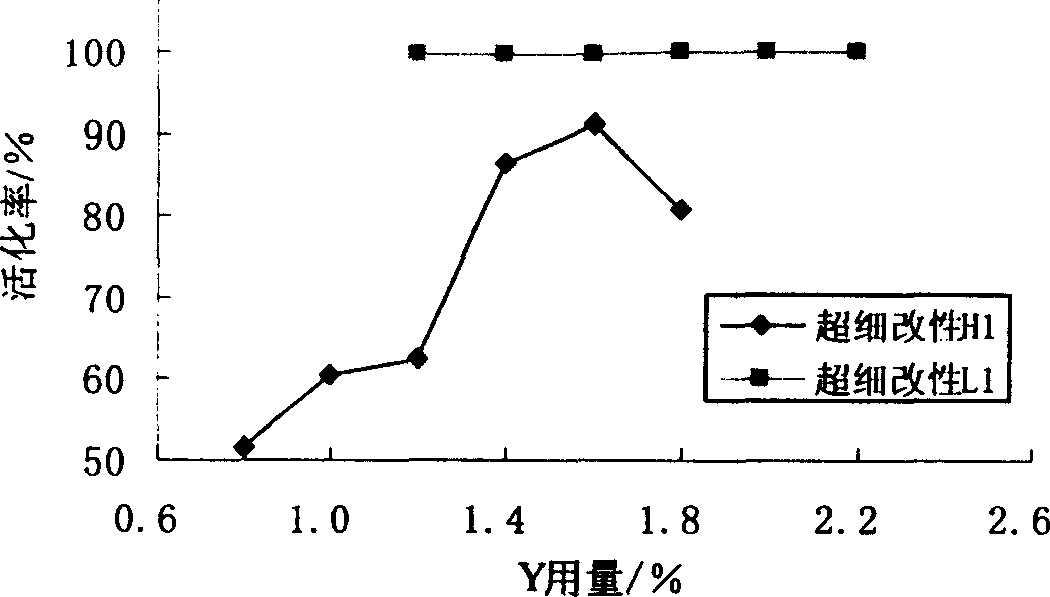

[0022] Heavy calcium sample H 1 Taken from the "Superfine Heavy Calcium Carbonate Factory in Western Hubei" in Yidu City, Hubei Province.

[0023] Light calcium sample L 1 Taken from Hubei Puqi "Chibi Yangfan Chemical Co., Ltd.".

[0024] (2) The chemical composition of the sample

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com