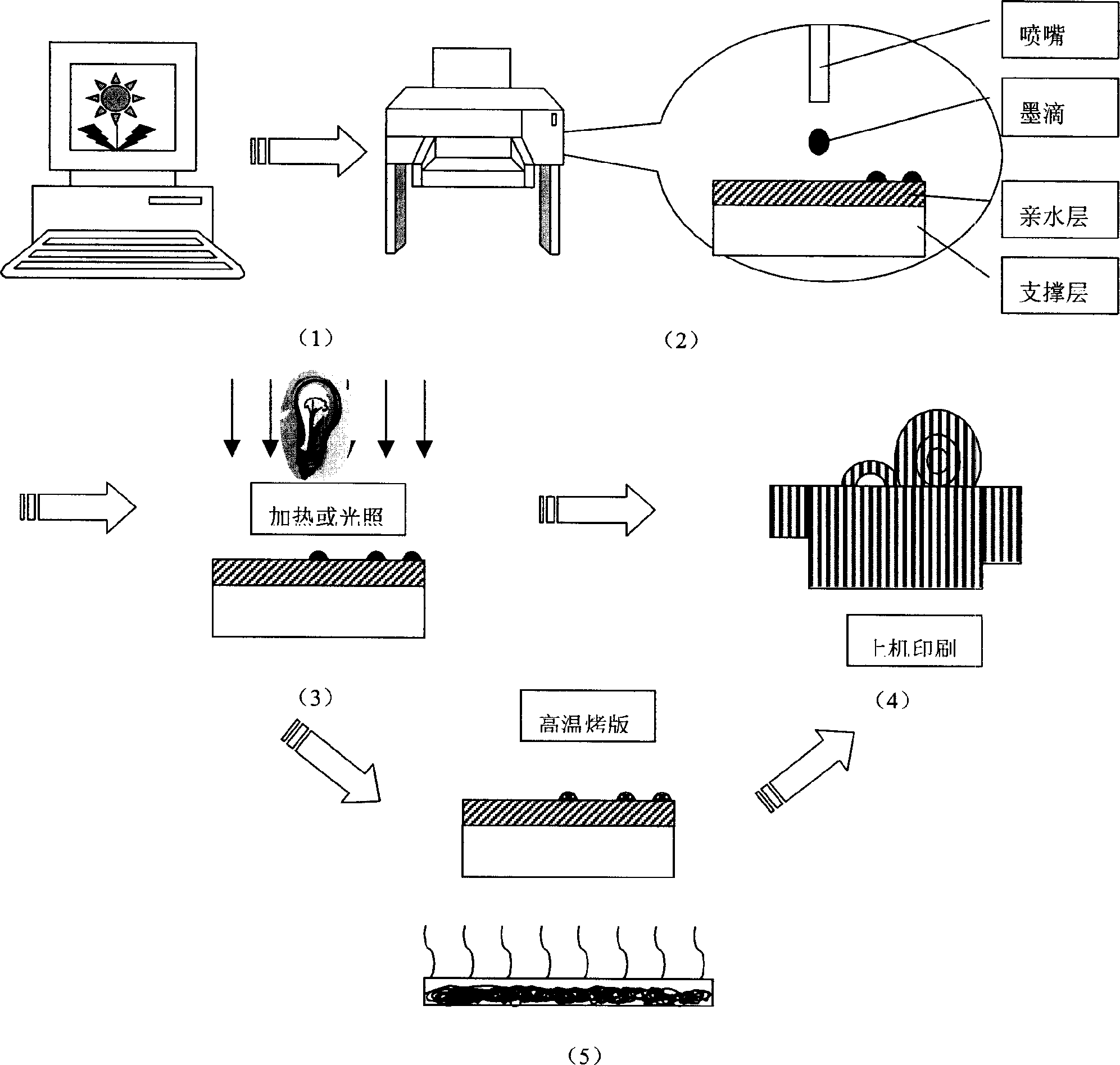

CTP plate making method and apparatus by using ink jet imaging principle

An imaging principle, direct technique, applied in photosensitive materials for optomechanical equipment, printing plate preparation, printing plates, etc., to achieve the effect of good dot reproducibility, improved image transfer quality, time and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The system uses EPSON 7600 inkjet plotter, Founder RIP software, EPSON original quick-drying ink and 0.15 mm thick aluminum base plate treated with electrochemical oxidation and coating method.

[0025] The image is output to the printer according to the color separation of the frequency-modulated hanging network by using Founder’s image-text processing color separation and hanging network RIP software. The printer sprays the ink onto the surface of the aluminum base plate, and after 1 minute of infrared radiation, the printing plate with a resolution of 2880DPI can be obtained. Its dot reproduction rate has reached 98%, fully able to meet the needs of 175LPI high-quality printing.

Embodiment 2

[0027] The system selected is EPSON 7600 inkjet plotter, Founder RIP software, ink prepared according to the patent application of "a nano-pigment ink for inkjet CTP plate making technology" and a coated 0.15 mm thick polycarbonamide base plate .

[0028] The image is output to the printer according to the color separation of the frequency-modulated hanging network by using Founder’s image-text processing color separation and hanging network RIP software. The printer sprays the ink onto the surface of the aluminum base plate, and after 1 minute of infrared radiation, the printing plate with a resolution of 2880DPI can be obtained. Its dot reproduction rate has reached 98%, fully able to meet the needs of 175LPI high-quality printing.

Embodiment 3

[0030] Mix the nano pigment particles (black) of 3% by weight with 5% phenolic resin, 20% ethanol, 2% glycerol, 70% ethylene glycol monoethyl ether, heat to 40 degrees Celsius and stir for 6 hours, and wait for the resin After dissolving and mixing uniformly, filter with a 0.5 micron filter membrane to obtain suitable nano-pigment ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com