Manufacturing method of optical fiber connector

A technology of optical fiber connector and manufacturing method, which is applied in the field of optical fiber communication, can solve the problems of low production efficiency, difficulty, and precision control below 1 μm, and achieve the effects of low production cost, simple manufacturing process, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

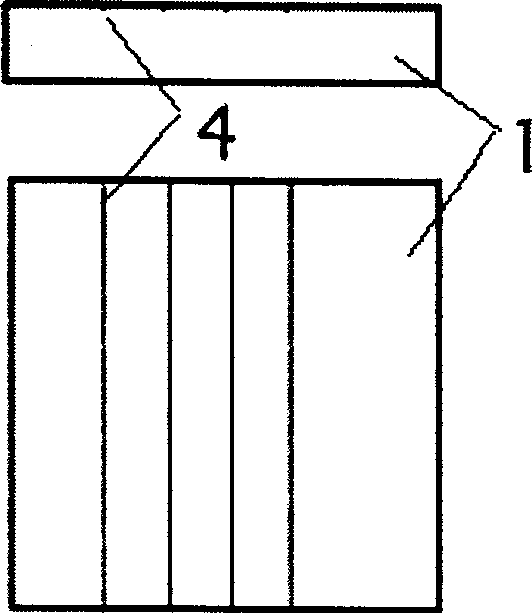

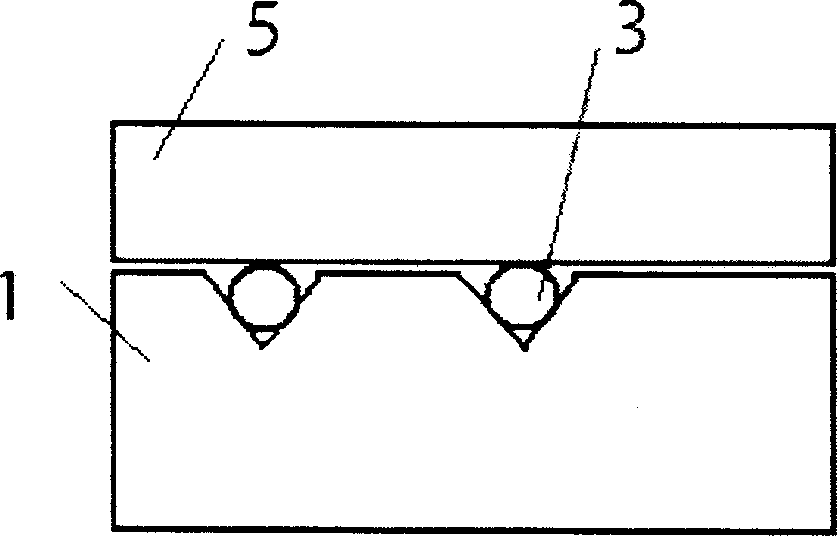

[0038] A 5mW femtosecond laser with a pulse frequency of 10Hz and a wavelength of 800nm was focused to 10μm above the surface of the polished substrate through a 100× lens, and scanned at 5μm / s to form 10 lines with an interval of 200μm. Then soak it in 4wt% hydrofluoric acid solution, apply ultrasonic wave for 1 hour, take it out and observe it under a microscope, it shows that V-shaped grooves are formed, and the dimensional accuracy between the grooves is 200±0.4μm. Put the optical fiber in the groove, and fix the optical fiber, the pressing plate and the substrate with the pressure plate and adhesive made of the same material as the substrate to form a connector for optical communication.

Embodiment 2

[0040] A 200mW femtosecond laser with a pulse frequency of 1kHz and a wavelength of 750nm was focused on the surface of the polished substrate through a 50× lens, and scanned at 100μm / s to form 10 lines with an interval of 200μm. Then soak it in 4wt% hydrofluoric acid solution, apply ultrasonic wave for 1 hour, take it out and observe it under a microscope, it shows that V-shaped grooves are formed, and the dimensional accuracy between the grooves is 200±0.4μm. Put the optical fiber in the groove, and fix it with the pressure plate and adhesive made of the same material as the substrate to form a connector for optical communication.

Embodiment 3

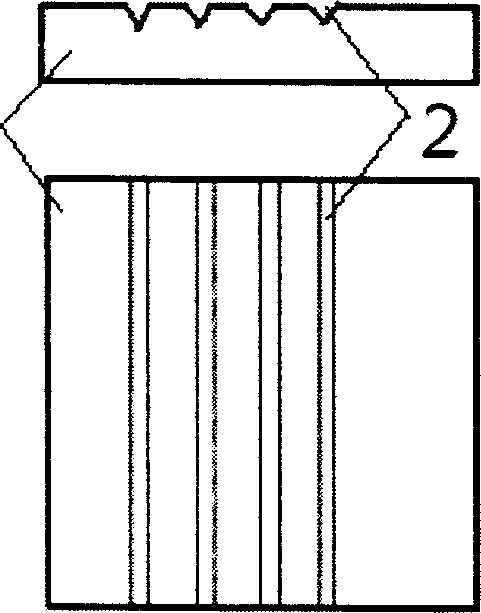

[0042] A 400mW femtosecond laser with a pulse frequency of 200kHz and a wavelength of 850nm was focused to 10 μm below the surface of the polished substrate through a 5× lens, and scanned at 5000 μm / s to form 10 lines with an interval of 200 μm. Then soak it in 4wt% hydrofluoric acid solution, apply ultrasonic wave for 1 hour, take it out and observe it under a microscope, it shows that U-shaped grooves are formed, and the dimensional accuracy between the grooves is 200±0.4 μm. Put the optical fiber in the groove, and fix it with the pressure plate and adhesive made of the same material as the substrate to form a connector for optical communication.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average power | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com