Variable-speed device

A continuously variable transmission, the same technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of complex structure, low power, and troublesome control of the continuously variable transmission, and prolong the overhaul interval. Effectiveness of mileage, high average speed, ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

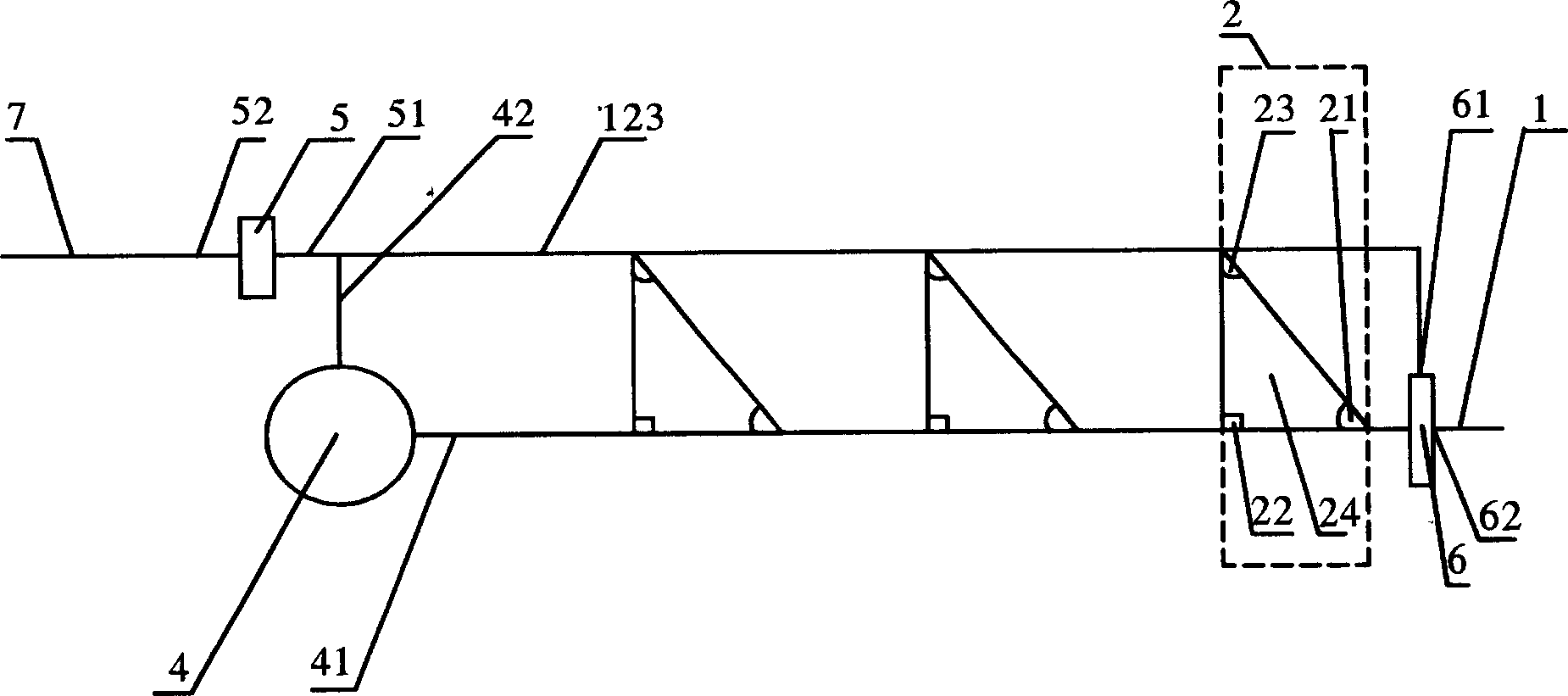

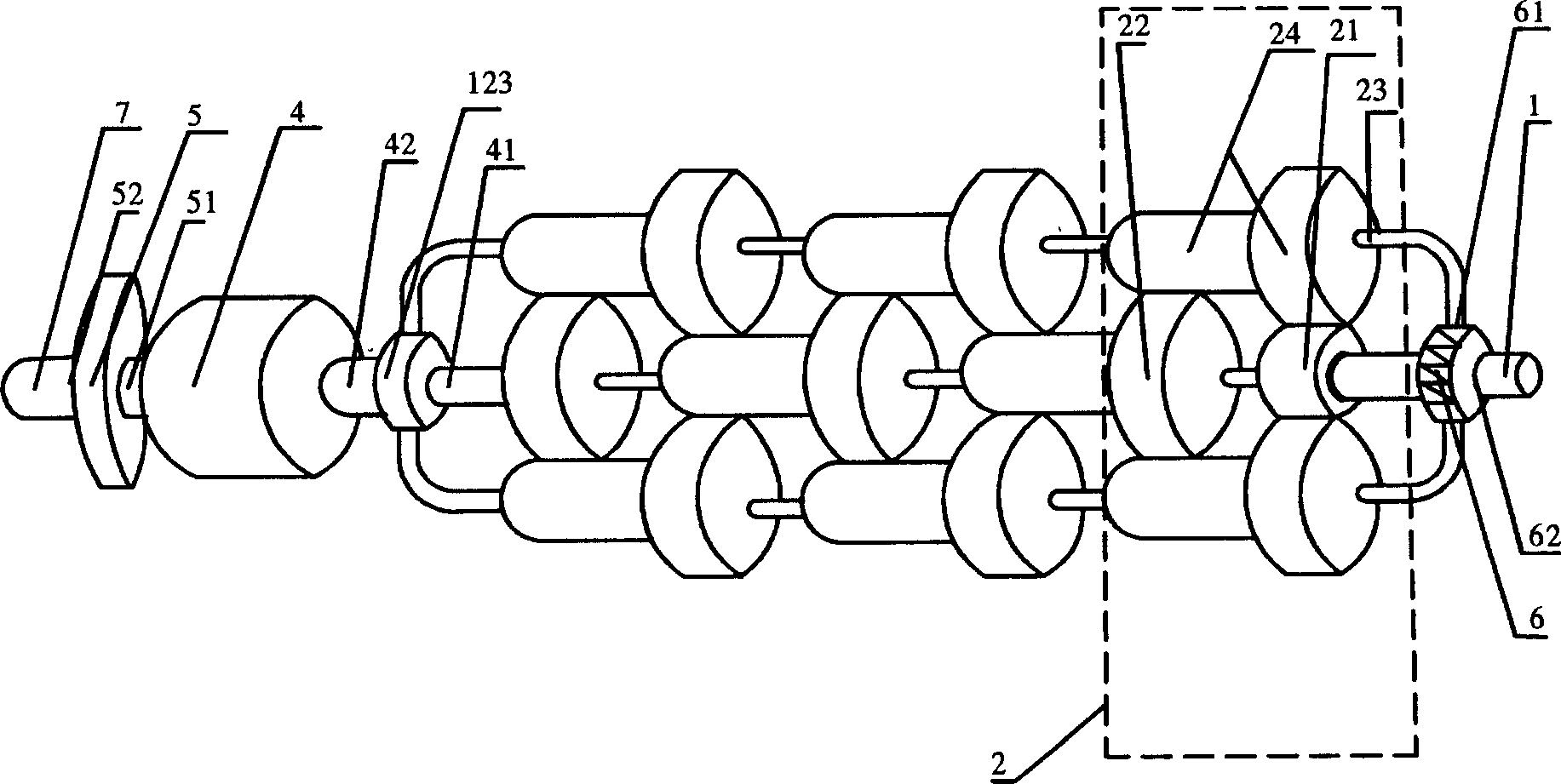

[0033] Such as figure 1 , figure 2 As shown in , a continuously variable transmission includes an input shaft 1, a controllable torque device 4, an empty reverse mechanism 5, a one-way clutch 6, and an output shaft 7, and the output end 62 of the one-way clutch 6 is connected to the input shaft 1 connection, the output end 42 of the controllable torque device 4 is connected with the input end 51 of the idle reverse gear mechanism 5, the output end 52 of the idle reverse gear mechanism 5 is connected with the output shaft 7, and three shafts are arranged between the input shaft 1 and the output shaft 7. A sequentially connected torque booster unit 2 composed of planetary rows with the same direction performance, said torque booster unit 2 includes input element 21, output element 22, common output element 23, planetary gear 24, the first torque booster unit 2 The input element 21 is connected with the input shaft 1, and the common output element 23 of each torque booster unit...

Embodiment 2

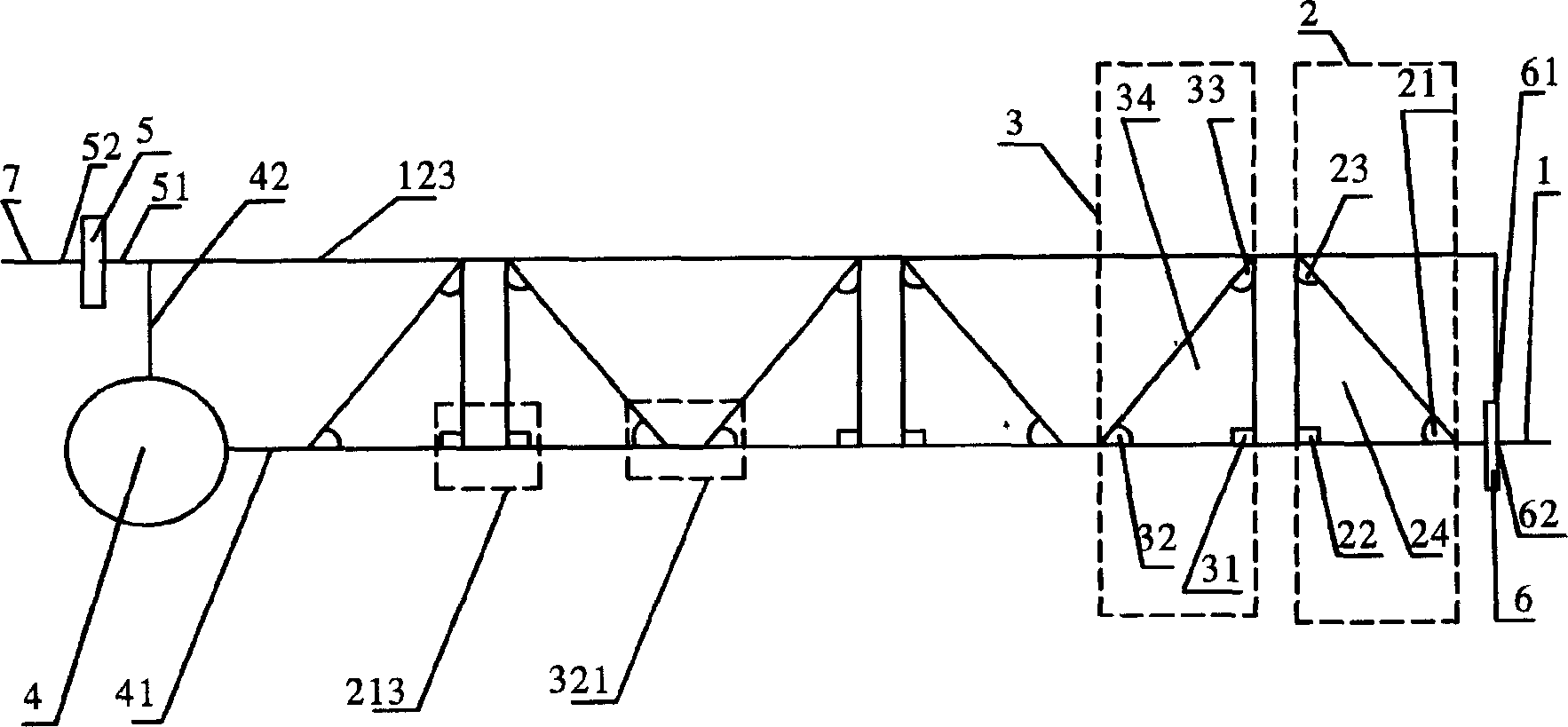

[0039] Such as image 3 , Figure 4 As shown in , it includes an input shaft 1, a controllable torque device 4, an idle reverse mechanism 5, a one-way clutch 6, and an output shaft 7. The output end 62 of the one-way clutch 6 is connected with the input shaft 1, and the controllable torque The output end 42 of the device 4 is connected with the input end 51 of the idle reverse gear mechanism 5, and the output end 52 of the idle reverse gear mechanism 5 is connected with the output shaft 7. The torque-increasing unit 2 composed of planetary rows with the same direction performance, each torque-increasing unit 2 is connected with a speed-up unit 3 composed of planetary rows with the same direction performance, and the speed-up unit 3 includes an input element 31, an output element 32. Common output element 33, planetary gear 34, the input element 21 of the first torque increasing unit 2 is connected with the input shaft 1, and the input elements 21 of the remaining torque incre...

Embodiment 3

[0046] Such as Figure 5 As shown in , this embodiment only changes the arrangement order of the torque increasing unit 2 and the speed increasing unit 3 that work together in the second embodiment, and its working principle and realized functions and effects remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com