Anti-slippage three dimensional warp knitted fabric

一种针织物、经编的技术,应用在立体结构经编针织物领域,能够解决弹性下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

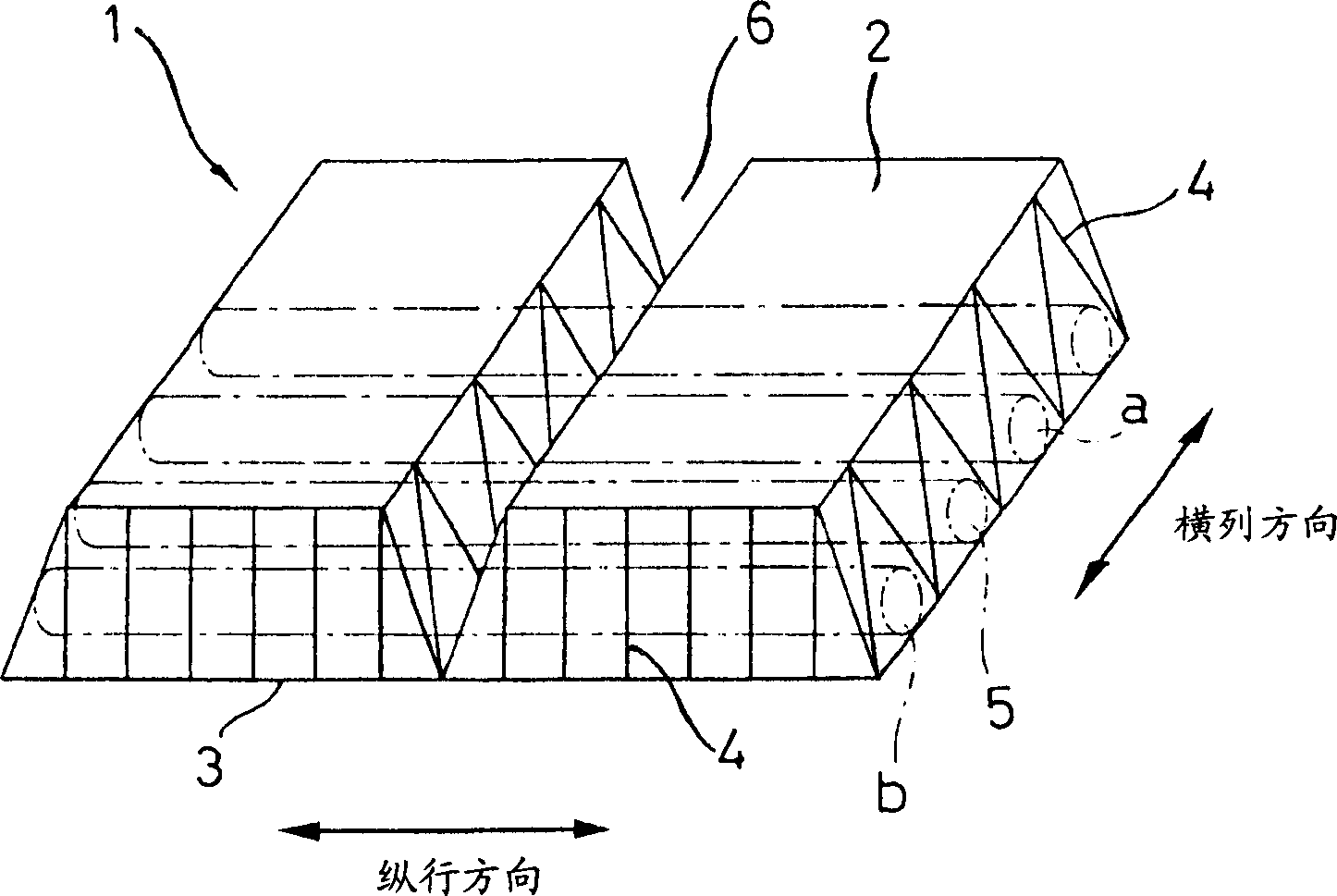

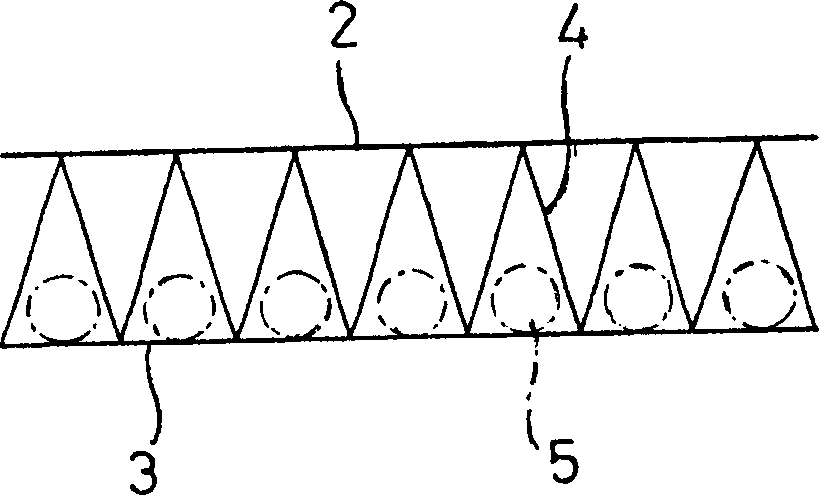

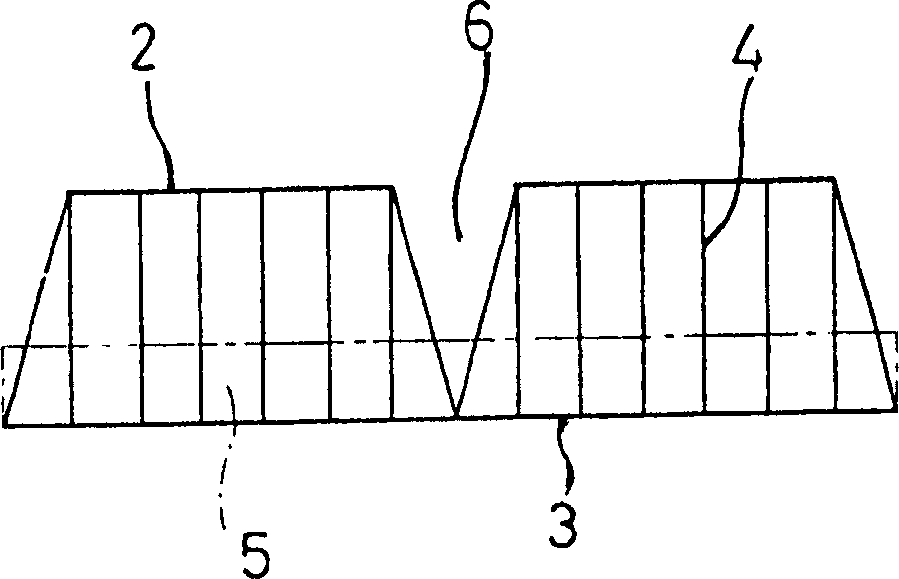

[0114] The double-needle seat Raschel knitting machine model RD6DPLM-77E-22G manufactured by KARL MAYER is used to produce Figure 4 The weave diagram shows the three-dimensional warp knitted fabric.

[0115] The weaving structure of the rear surface is formed on the bar L-1, the weaving structure of the front surface with openings is formed on the bar L-5 and L-6, and the connecting yarn on the bar L-3 connects these weaving structures connected. Then, the fixing yarn on the bar L-4 fixes the interlining yarn of 950dtex on the bar L-2 against the opening position along the inside of the ground weaving structure (that is, fixing inside the back surface ground weaving structure) . The finished product density of the three-dimensional warp knitted fabric woven in this way is 36 courses: 23 wales, and the thickness is 3.0mm.

[0116] Unit area weight (mass) is 550g / m 2 .

[0117] The number of overlapping yarns fixed together with interlining yarns between the wales was 2, a...

Embodiment 2

[0121] The double-needle seat Raschel knitting machine model RD6DPLM-77E-22G manufactured by KARL MAYER is used to produce Figure 5 The weave diagram shows the three-dimensional warp knitted fabric.

[0122] The weaving structure of the rear surface is formed on the bar L-1, the weaving structure of the front surface with openings is formed on the bar L-5 and L-6, and the connecting yarn on the bar L-3 connects these weaving structures connected. Then, the fixing yarn on the bar L-4 fixes the 1250 dtex inserting yarn on the bar L-2 along the inside of the weave weave on the back surface. The finished product density of the three-dimensional warp knitted fabric woven in this way is 36 courses: 23 wales, and the thickness is 3.0mm.

[0123] Weight per unit area is 580g / m 2 .

[0124] The number of overlapping yarns fixed together with interlining yarns between the wales was 3, and the fineness of the yarns between the wales was 3750 dtex.

[0125] Lining density is 0.196g / cm...

Embodiment 3

[0128] The double-needle seat Raschel knitting machine model RD6DPLM-77E-22G manufactured by KARL MAYER is used to produce Image 6 The weave diagram shows the three-dimensional warp knitted fabric.

[0129] The weaving structure of the rear surface is formed on the bar L-1, the weaving structure of the front surface with openings is formed on the bar L-5 and L-6, and the connecting yarn on the bar L-3 connects these weaving structures connected. Then, the fixing yarn on the bar L-4 fixes the 750 dtex inserting yarn on the bar L-2 inside the weave weave along the back surface. The finished product density of the three-dimensional warp knitted fabric woven in this way is 36 courses: 23 wales, and the thickness is 3.0mm.

[0130] Weight per unit area is 560g / m 2 .

[0131] The number of overlapping yarns fixed together with interlining yarns between the wales was 4, and the fineness of the yarns between the wales was 3000 dtex.

[0132] Lining density is 0.173g / cm 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com