Vacuum-generating apparatus and thin film processing apparatus having the same

A technology for generating device and vacuum pressure, applied in the field of film forming device and vacuum pressure generating device, can solve the problems of reduced uniformity of vacuum pressure, reduced quality of liquid crystal display panel film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

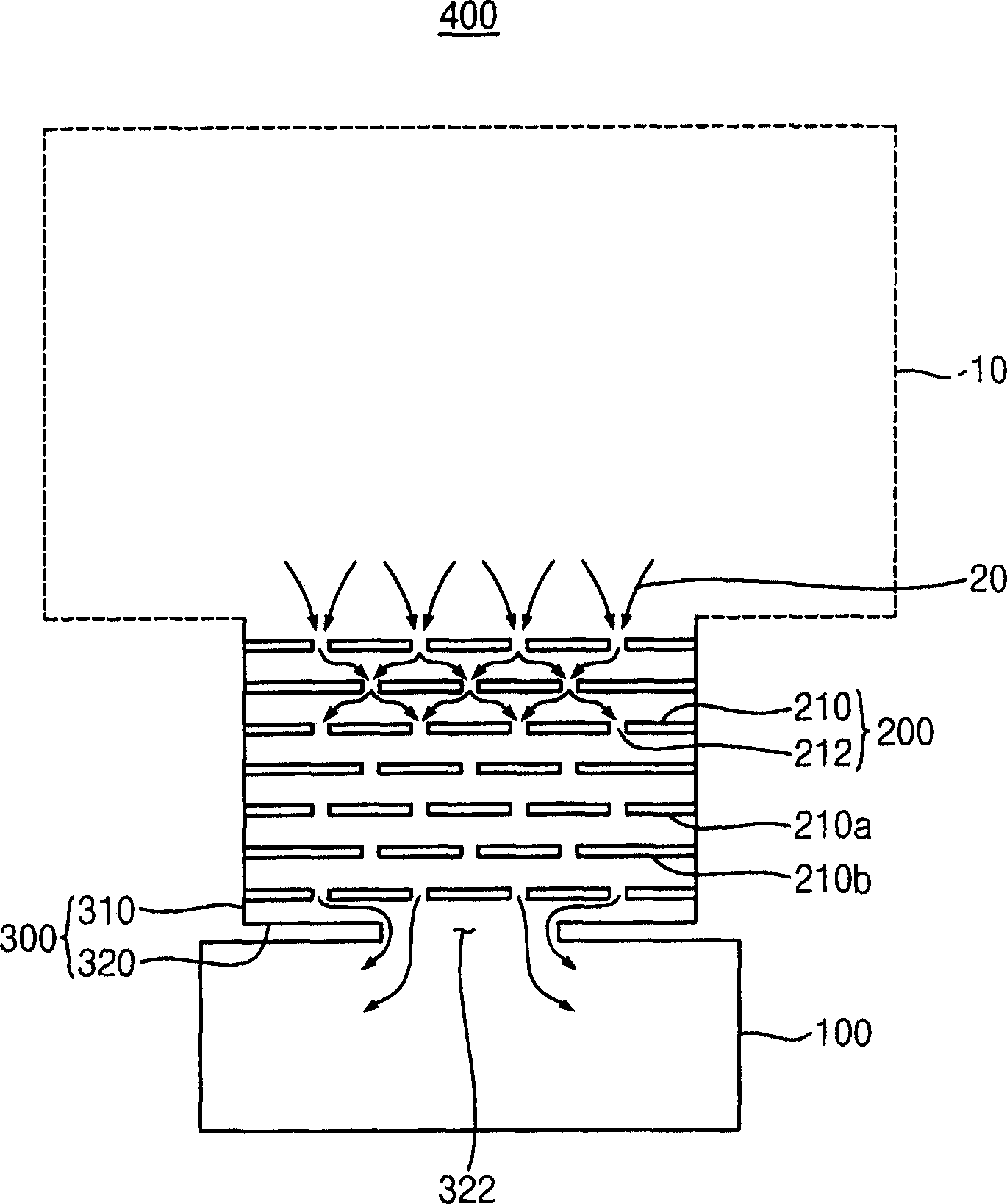

[0031] figure 1 is a schematic sectional view of a vacuum pressure generating device according to a first embodiment of the present invention, figure 2 is shown figure 1 An exploded perspective view of the exhaust plate of the medium vacuum pressure generating device.

[0032] refer to figure 1 and figure 2 , the vacuum generating device 400 according to this embodiment includes a vacuum generating unit 100 and a stabilization module 200 .

[0033] The vacuum generation unit 100 exhausts fluid in the process area 10 to form a vacuum pressure, for example, exhaust gas forms a vacuum pressure inside the process area 10 .

[0034] An example of the vacuum pressure generating unit 100 according to the present embodiment is a vacuum pump that exhausts gas in the process area 10 through a rotational motion within a motor. In addition, the vacuum generation unit 100 may use any device that can exhaust the gas inside the process area 10 .

[0035] The stabilization module 200 ...

Embodiment 2

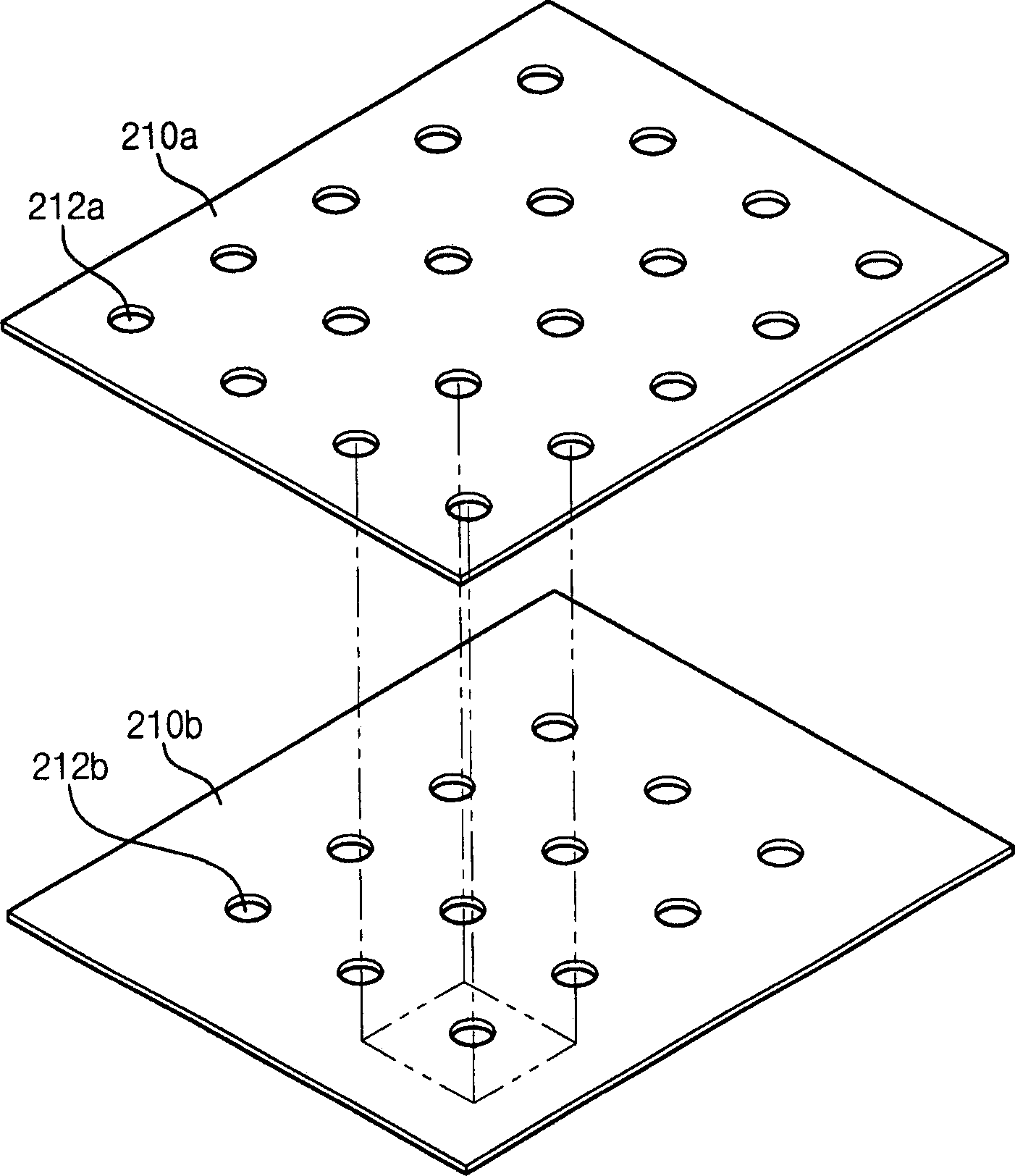

[0047] image 3 is an exploded perspective view showing an exhaust plate of a vacuum pressure generating device according to a second embodiment of the present invention. The vacuum pressure generating device according to the second embodiment of the present invention has the same structure as the vacuum pressure generating device of the first embodiment described above except for the stabilizing module, so repeated description thereof is omitted, and for the same constituent elements Indicated by the same reference symbols and names.

[0048] refer to image 3 , the vacuum pressure generating device 400 according to this embodiment includes a vacuum pressure generating unit 100 and a stabilization module 200 .

[0049] The stabilization module 200 according to this embodiment is placed between the process area 10 and the vacuum pressure generating unit 100 to improve the uniformity of the vacuum pressure in the process area 10 . The stabilization module 200 has at least tw...

Embodiment 3

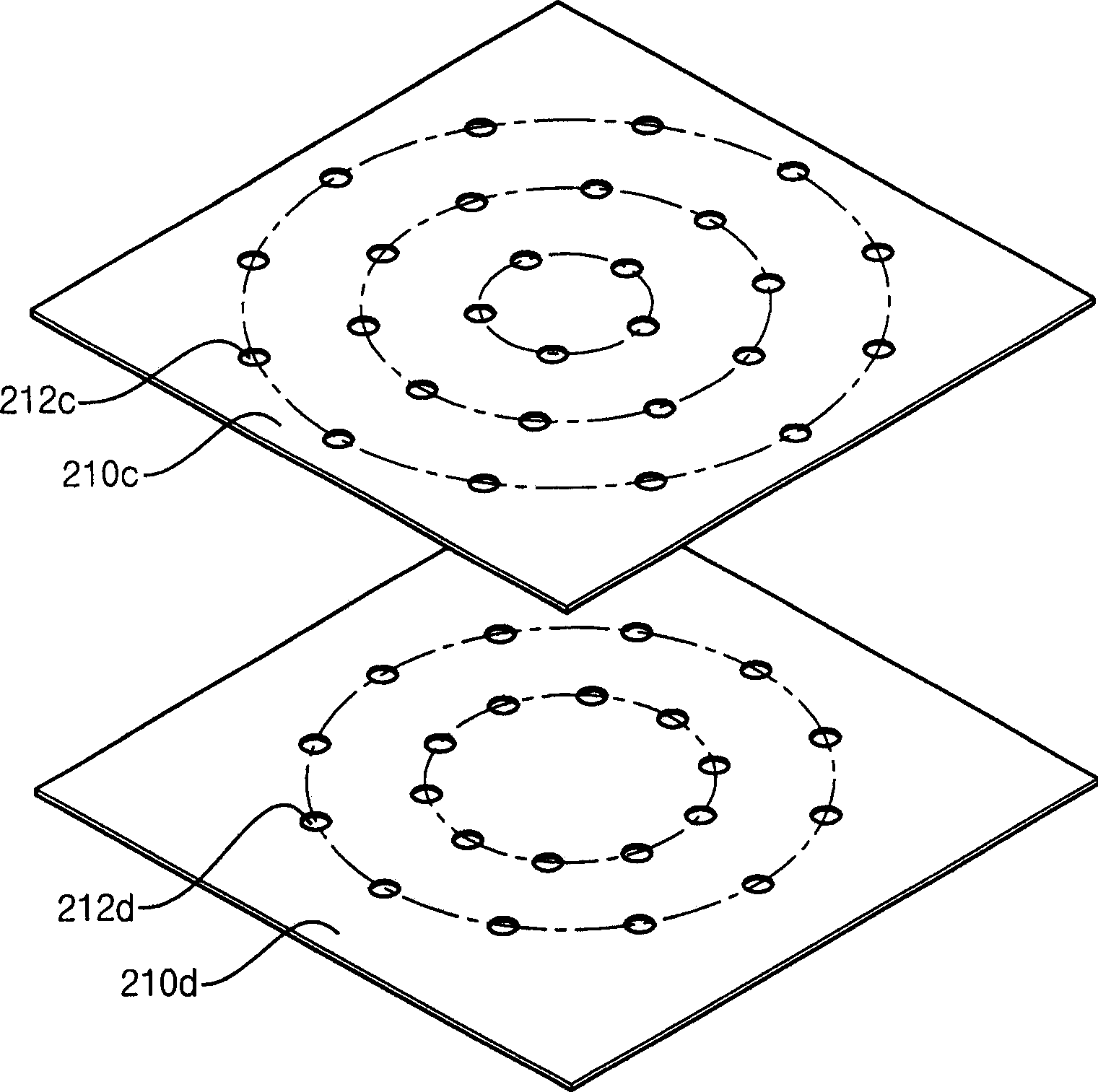

[0059] Figure 4 is an exploded perspective view showing an exhaust plate of a vacuum pressure generating device according to a third embodiment of the present invention. The vacuum pressure generating device according to the third embodiment of the present invention has the same structure as the vacuum generating device of the first embodiment except for the stabilizing module, so repeated description thereof is omitted, and the same components are used for the same components. Refer to symbols and names.

[0060] refer to Figure 4 , the vacuum pressure generating device 400 according to this embodiment includes a vacuum pressure generating unit 100 and a stabilization module 200 .

[0061] The stabilization module 200 according to this embodiment is placed between the process area 10 and the vacuum pressure generating unit 100 to improve the uniformity of the vacuum pressure in the process area 100 . The stabilization module 200 has fluid channels, for example, at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com