Smoke exhaust ventilator

A range hood and impeller technology, applied in the field of range hoods, can solve the problems of stained windows and external walls, unhygienic appearance, and reduced exhaust efficiency, and achieve easy collection and discharge, high power, and exhaust efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

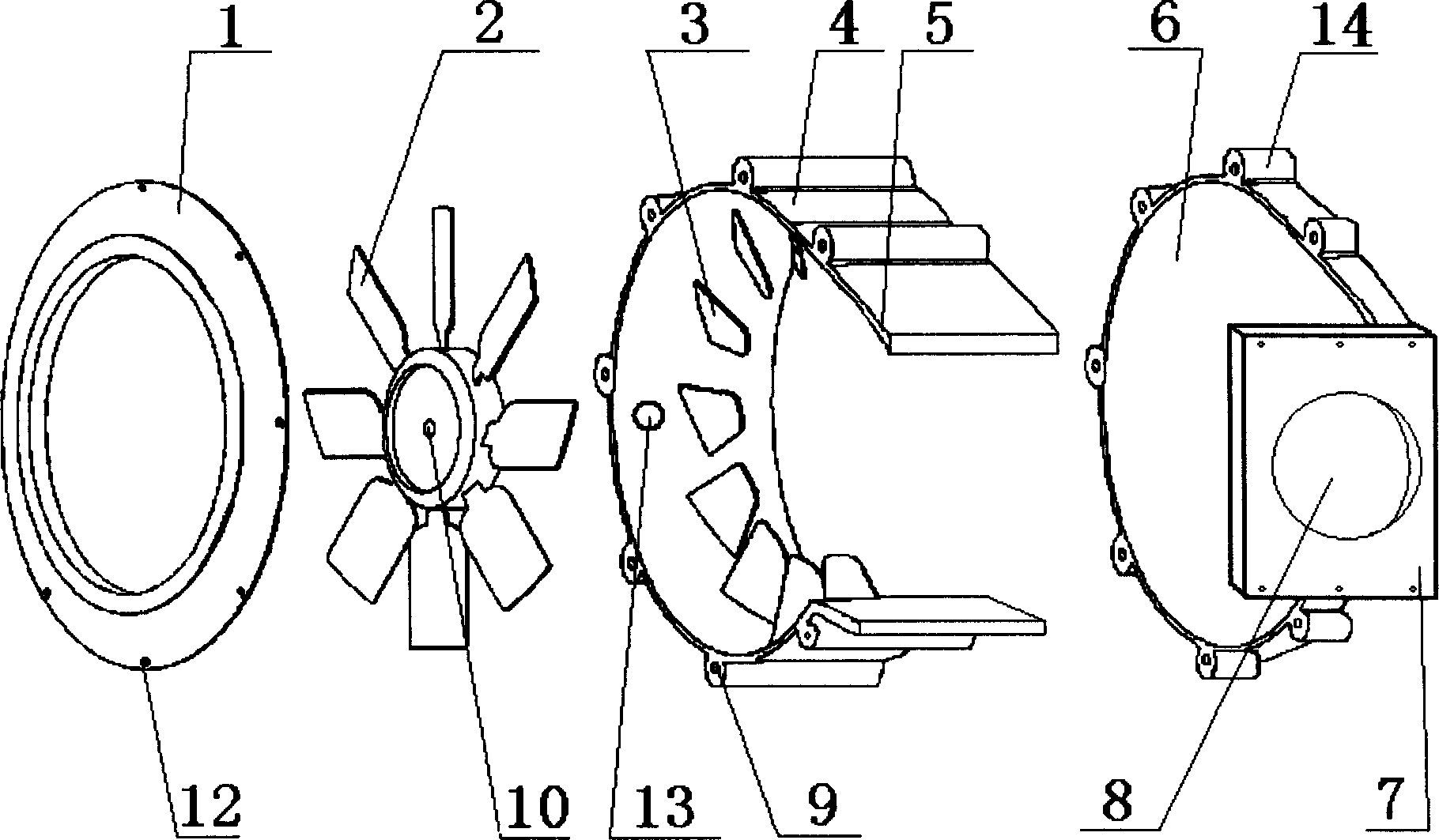

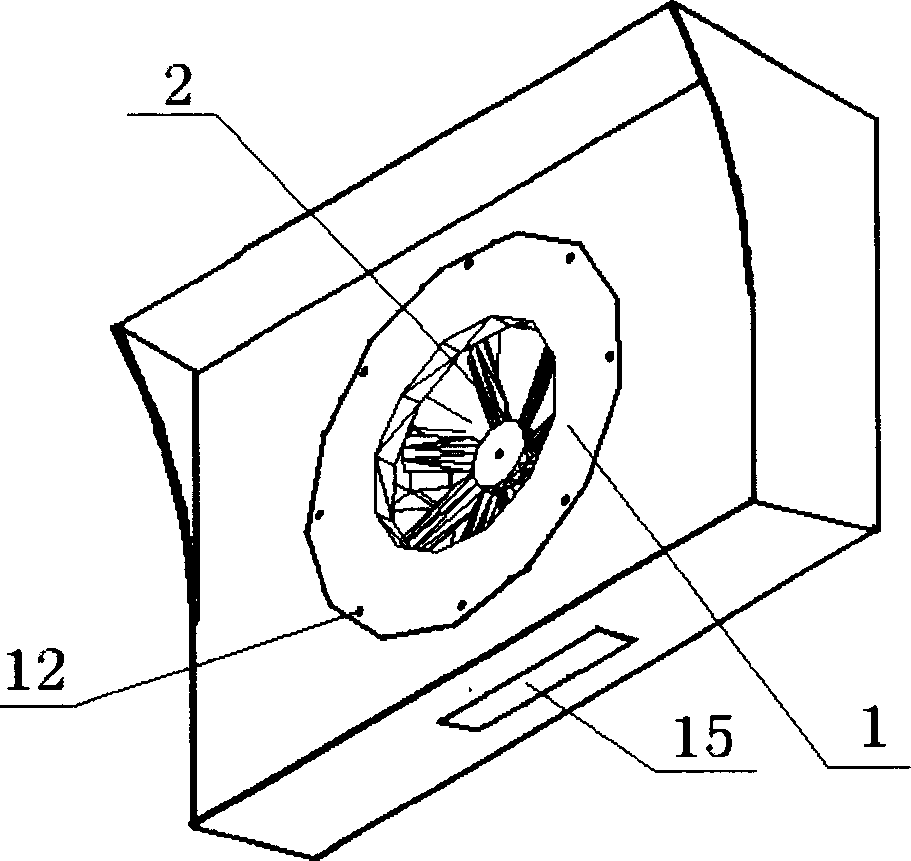

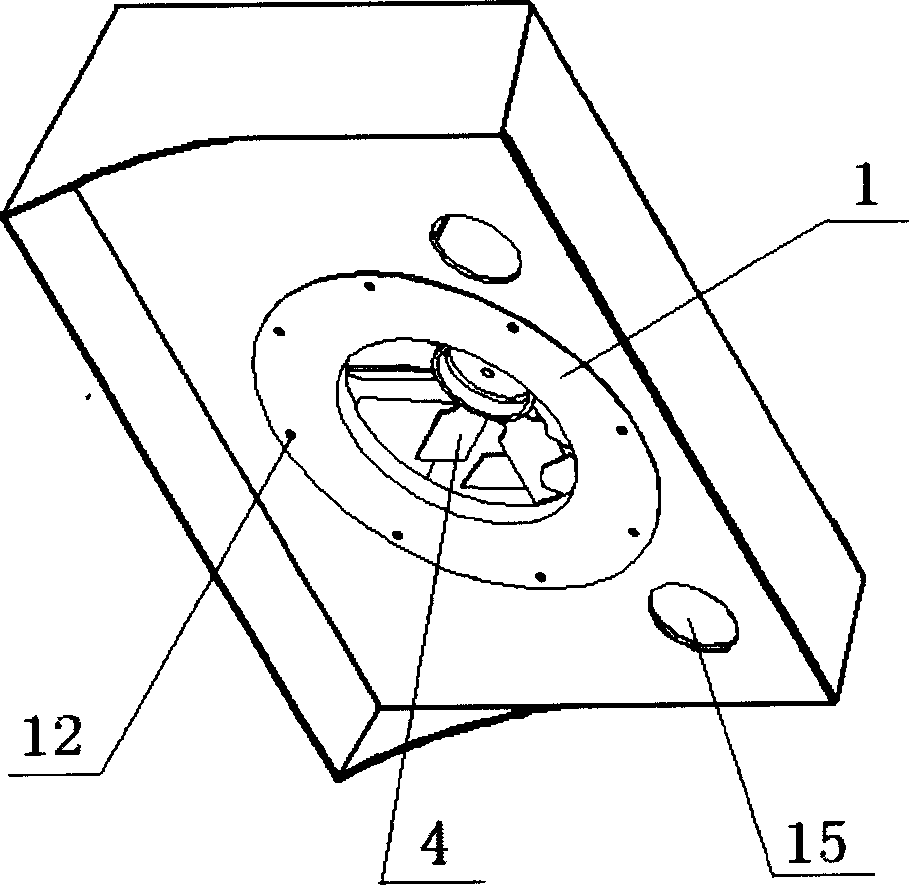

[0016] Embodiment 1: The plane where the impeller is located is perpendicular to the ground, which is called the side suction type, and its exhaust port faces upwards, and then it is led out of the room with a pipe. Side suction such as figure 1 , figure 2 , Figure 4 , the impeller 2 is placed in the air drum 4, one end of the impeller 2 in the axial direction is the panel 1, the other end is the deflector 3, the exhaust port 8 is arranged in the circumferential direction of the impeller 2, and the oil outlet 13 is arranged at the bottom of the air drum 4 . The guide vanes 3 are distributed at intervals on the inside of the wind drum and in a circular plane parallel to the impeller, and the angle between it and the circumferential line is 22 degrees; there is an exhaust passage 5 between the exhaust port 8 and the impeller 2; the panel 1 There is a windshield ring 11 inboard of the air inlet.

[0017] Panel 1, air drum 4, exhaust aisle 5, and front baffle 6 form a closed...

Embodiment approach 2

[0022] Embodiment 2: If the plane where the impeller 2 is located is parallel to the ground, it is called a top suction type, and its exhaust port is led out of the room through the wall or window forward. The oil outlet 13 is located at the plane where the panel is located, and the oil and water can be caught with the oil box 15 again. The deflectors 3 are distributed on the inner wall of the wind drum 4 at intervals and in a circular plane parallel to the impeller, the angle between the blades of the impeller 2 and the circumference is 18 degrees, and the angle between the blades of the impeller 2 and the circumference is 28 degrees. Windshield ring 11 adopts Figure 5 "L" shape shown. Except for the parameters in Table 1, the rest are the same as Embodiment 1.

Embodiment approach 3

[0023] Embodiment 3: The deflectors 3 are distributed at intervals on the inner side of the wind drum and in a circular plane parallel to the impeller, the angle between it and the circumference line is 30 degrees, and the angle between the blades of the impeller 2 and the circumference line is 50 degrees Spend. Windshield ring 11 adopts Figure 6 "I" shape shown. The rest are the same as Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com