High-low temperature changeable graded evaporation air-conditioner heat pump water heater

A technology for heat pump water heaters and evaporative air conditioners, which is applied in the direction of reversible cycle compressors, lighting and heating equipment, fluid circulation arrangements, etc., and can solve problems such as system failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

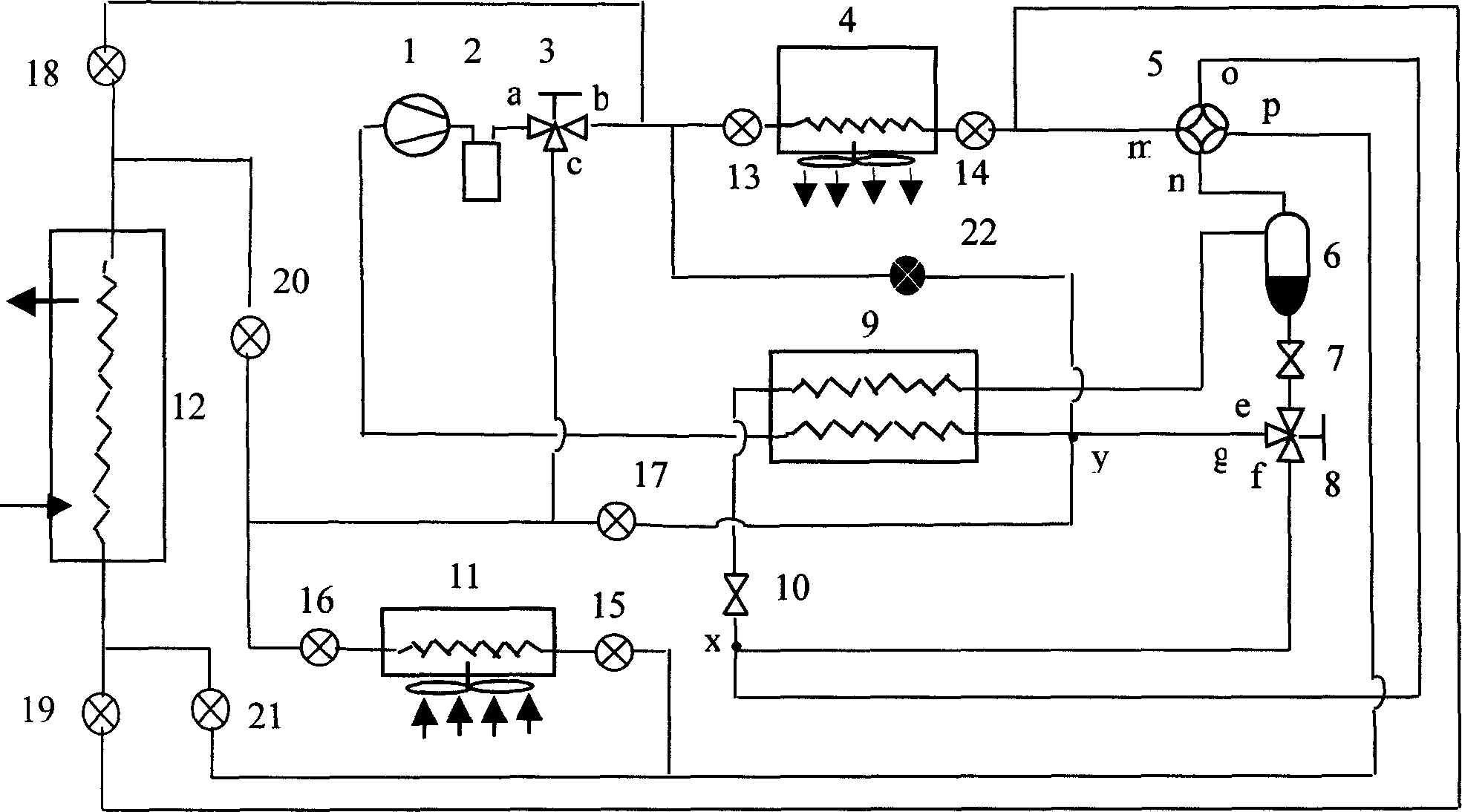

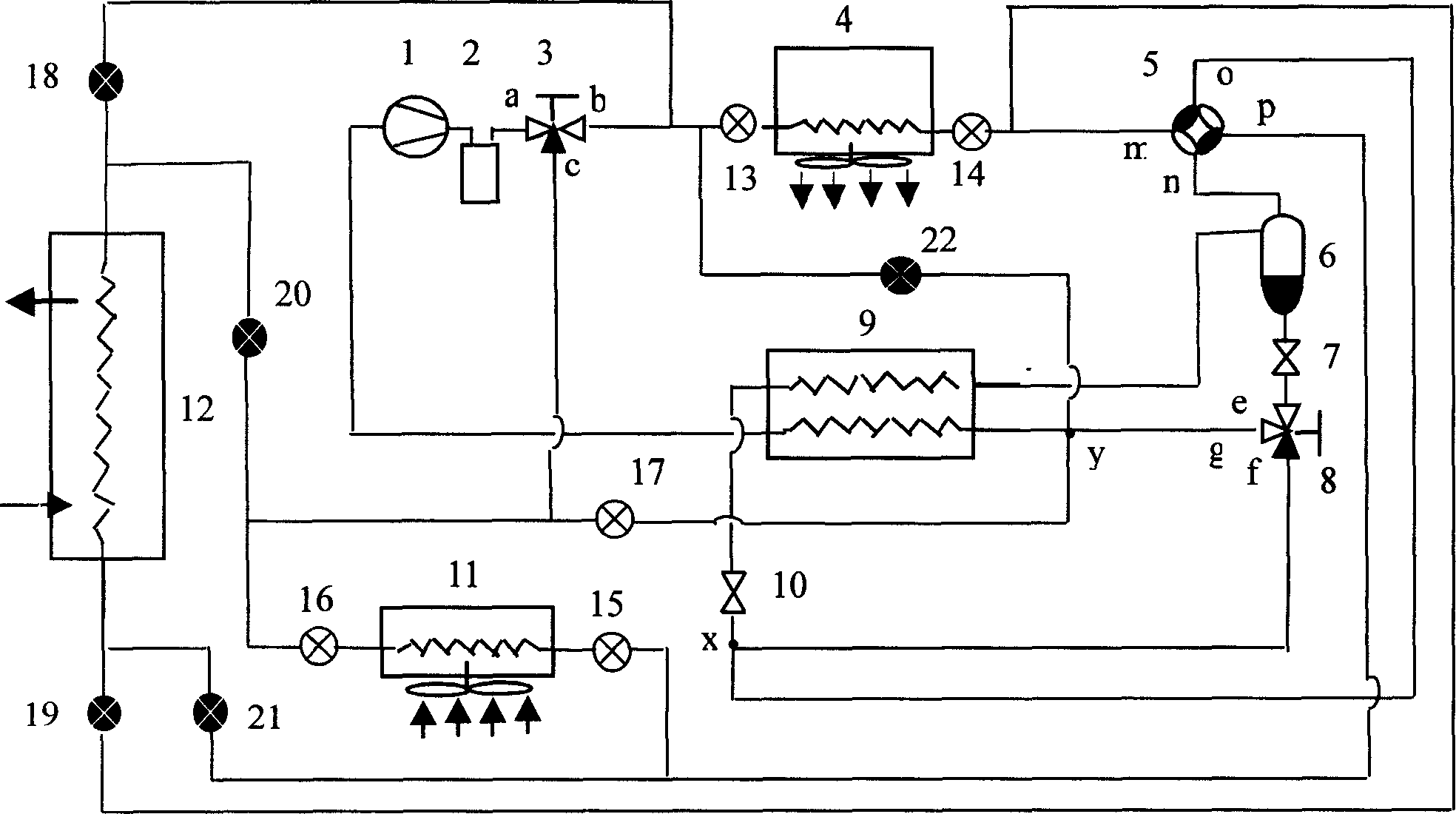

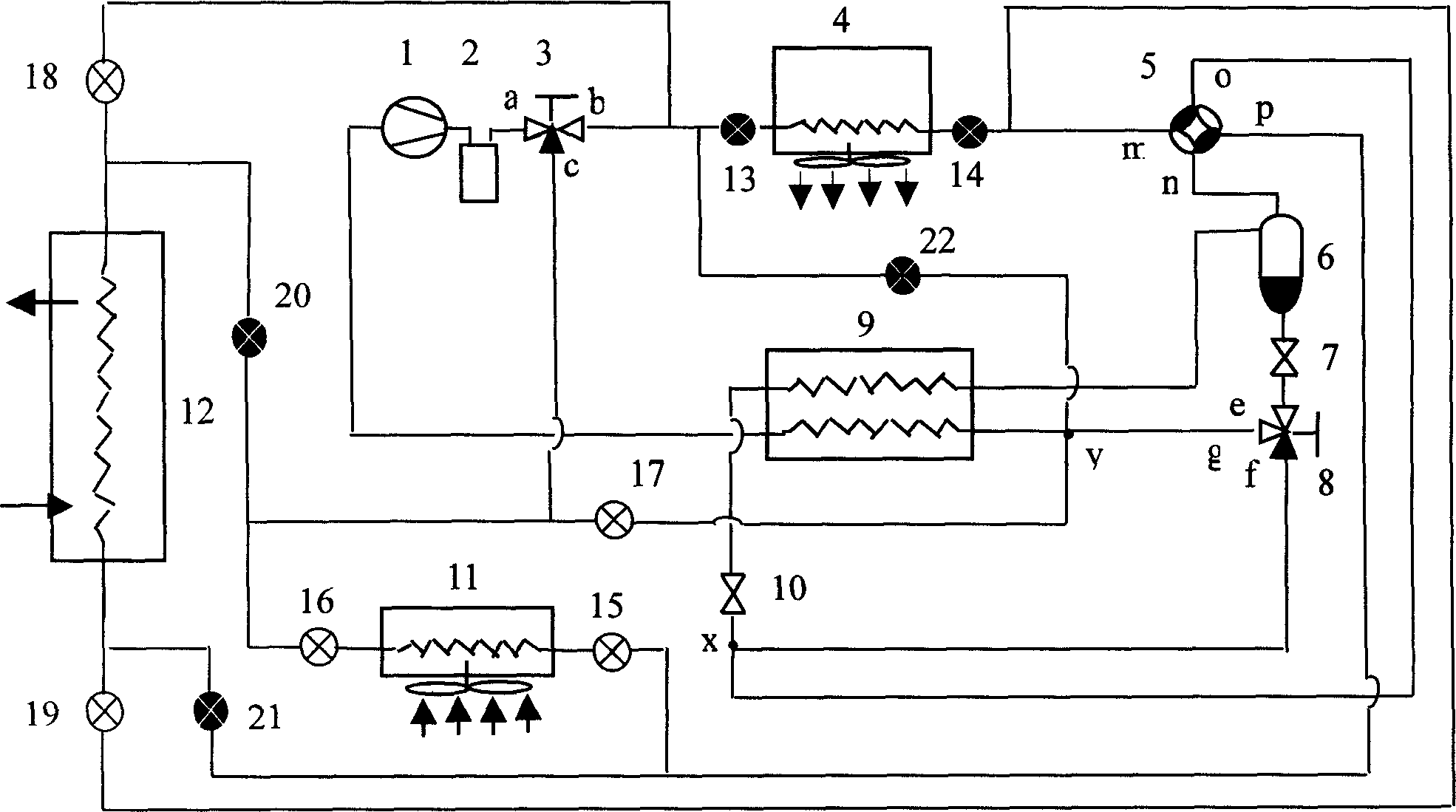

[0022] The structural principle and working principle of the circulation system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] see figure 1 , the high and low temperature switchable, graded evaporative air conditioner heat pump water heater of the present invention includes a refrigeration compressor 1, an oil-gas separator 2, a first reversing three-way solenoid valve 3, an indoor air-cooled condenser (ie, an air heater) or an indoor air-cooled condenser. Cold evaporator (that is, air cooler) 4, reversing four-way solenoid valve 5, rectification gas-liquid separator 6, first throttle valve 7, second reversing three-way solenoid valve 8, heat exchanger 9, second Throttle valve 10, outdoor air-cooled evaporator or outdoor air-cooled condenser 11, indoor water-cooled condenser (ie water heater) 12, first solenoid valve 13, second solenoid valve 14, third solenoid valve 15, fourth solenoid valve 16. The fifth el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com