Control actuator of engine for movable pipeline pump set

A technology for controlling actuators and engines, which is applied in engine control, machines/engines, mechanical equipment, etc. It can solve the problems of low comparison accuracy and tracking accuracy of analog circuits, easy to be affected by temperature changes, poor followability, etc., and achieve high conversion Accuracy and stability, the effect of extending reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

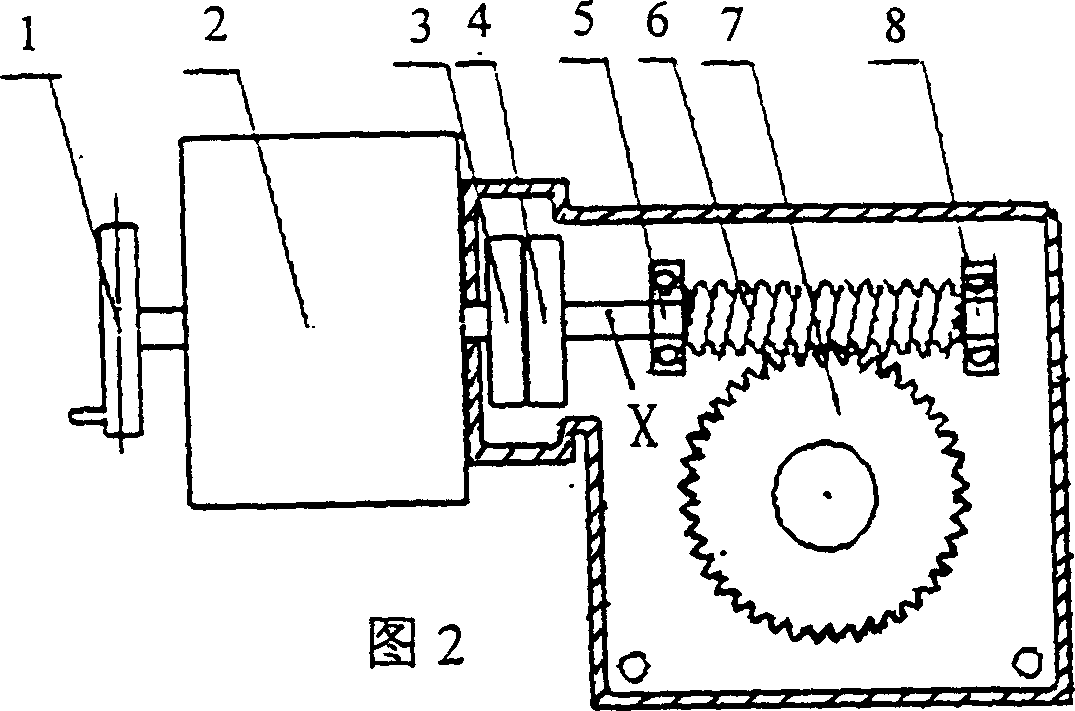

[0060] The engine of the pipeline pump unit can generally be operated by mechanical manual when it is started. Psychologically speaking, and in terms of system design requirements, there is generally a mechanical manual operation part. During operation, when the handwheel is turned clockwise, the engine speed increases, and counterclockwise means deceleration.

[0061] Generally speaking, when the inlet pressure of the pump is relatively high, the hand wheel turns clockwise, the worm gear drives the flexible tendons, tightens the engine throttle, the engine speeds up, the pump also speeds up, and when the pump inlet pressure drops to an appropriate pressure, the machine stops. Manual operation, the speed of the pump unit is maintained at this speed.

[0062] The real meaning is that when the operation of the electric and automatic systems is inflexible, the pump unit is operated manually by mechanical hands.

Embodiment 2

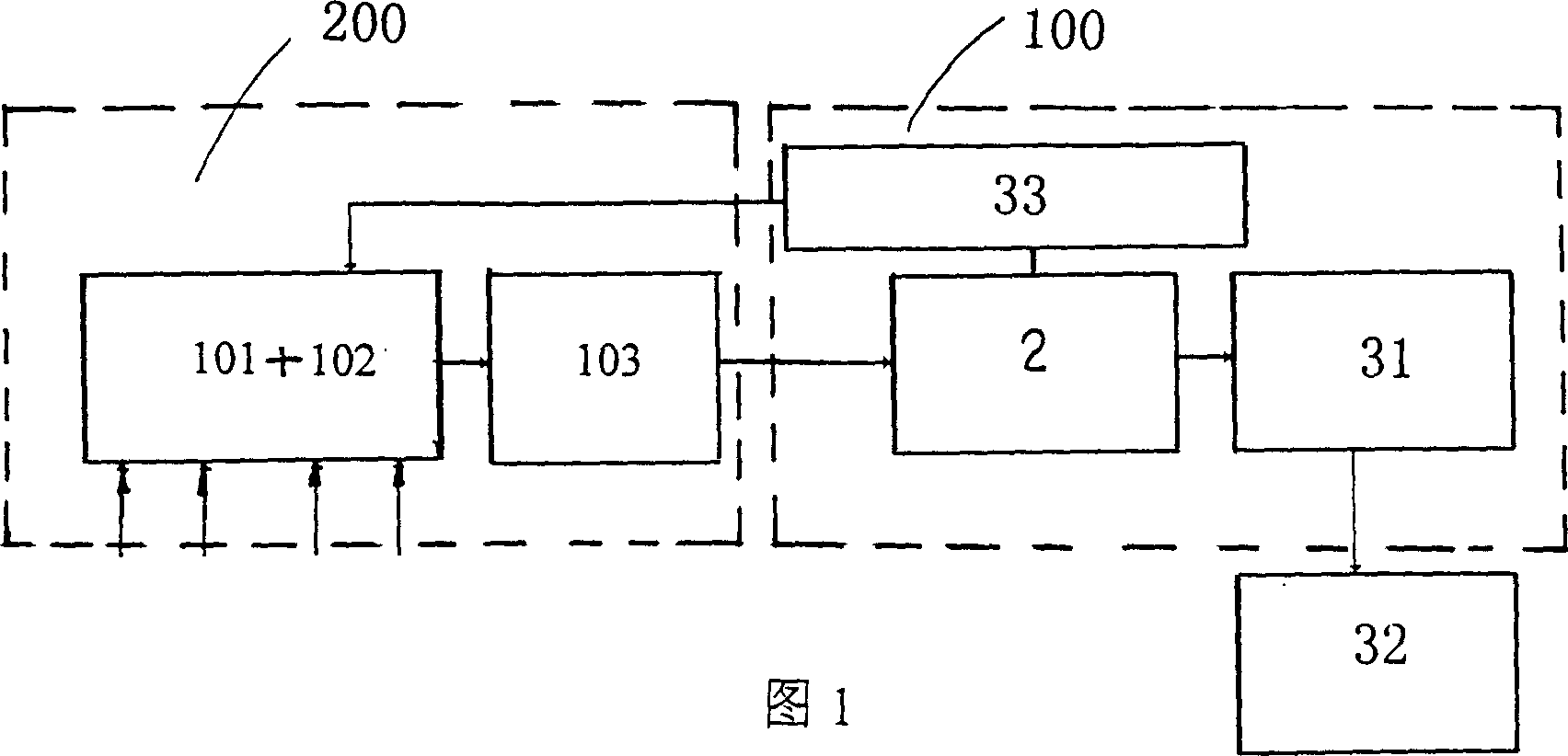

[0064] Pin 8 of the single-chip microcomputer 101 is an automatic / electric state switch input terminal, low level is electric, and high level is automatic. The low level of pin 6 is for the electric forward rotation engine to speed up, and the low level of pin 7 is for the electric reverse engine to slow down.

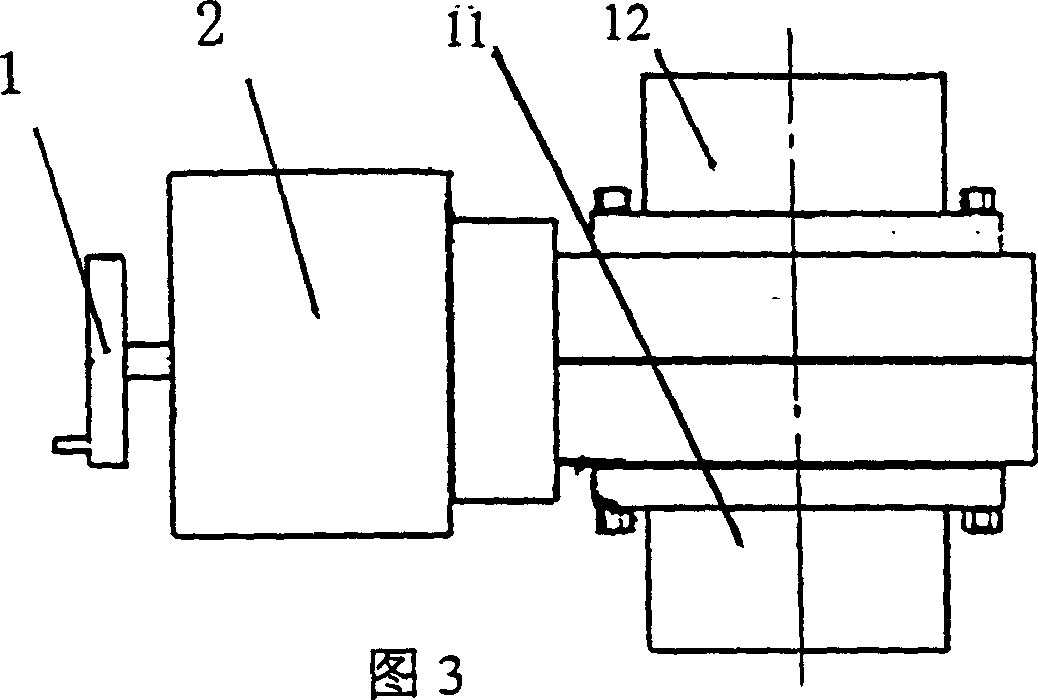

[0065] When the engine of the pipeline pump unit starts to run, first move the automatic / electric state switch to the electric position, and use the electric manual to operate. It is flexible, easy to operate, stable and reliable. When the pipeline system is running and the pump inlet pressure is relatively high, Press the engine speed-up button, when the 6 pins of the single-chip microcomputer 101 are at a low level, the forward rotation control signal voltage is output from the RC7 of the I / O port of the PIC series single-chip microcomputer 101 to the PWM pulse width modulation power amplifier 103 connected thereto Forward rotation control signal receiving end; the f...

Embodiment 3

[0069] Pin 8 of the single-chip microcomputer 101 is an automatic / electric state switch input terminal, low level is electric, and high level is automatic.

[0070] After the whole pipeline system runs stably, set the value of the pump inlet pressure to a given value, move the automatic / electric state switch to the automatic position, and the entire automatic control system enters the automatic state.

[0071]The A / D conversion module 102 converts the 0-5V analog control voltage output by the microcomputer and the 0-5V angular voltage fed back by the actuator throttle position feedback device 33 into digital signals in the A / D conversion module 102, and then transmits them in time division Give the PIC series single-chip microcomputer 101, after the PIC series single-chip microcomputer 101 compares the two signals, when the analog control voltage is greater than the corner voltage, output the positive rotation control signal voltage from the RC7 of the I / O port of the PIC serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com