Sealed, thermally insulated tank incorporated into the load-bearing structure of a ship

A technology for load-bearing components and thermal insulation, applied in the direction of hull parts, hulls, hull panels, etc., can solve problems such as a large number of assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

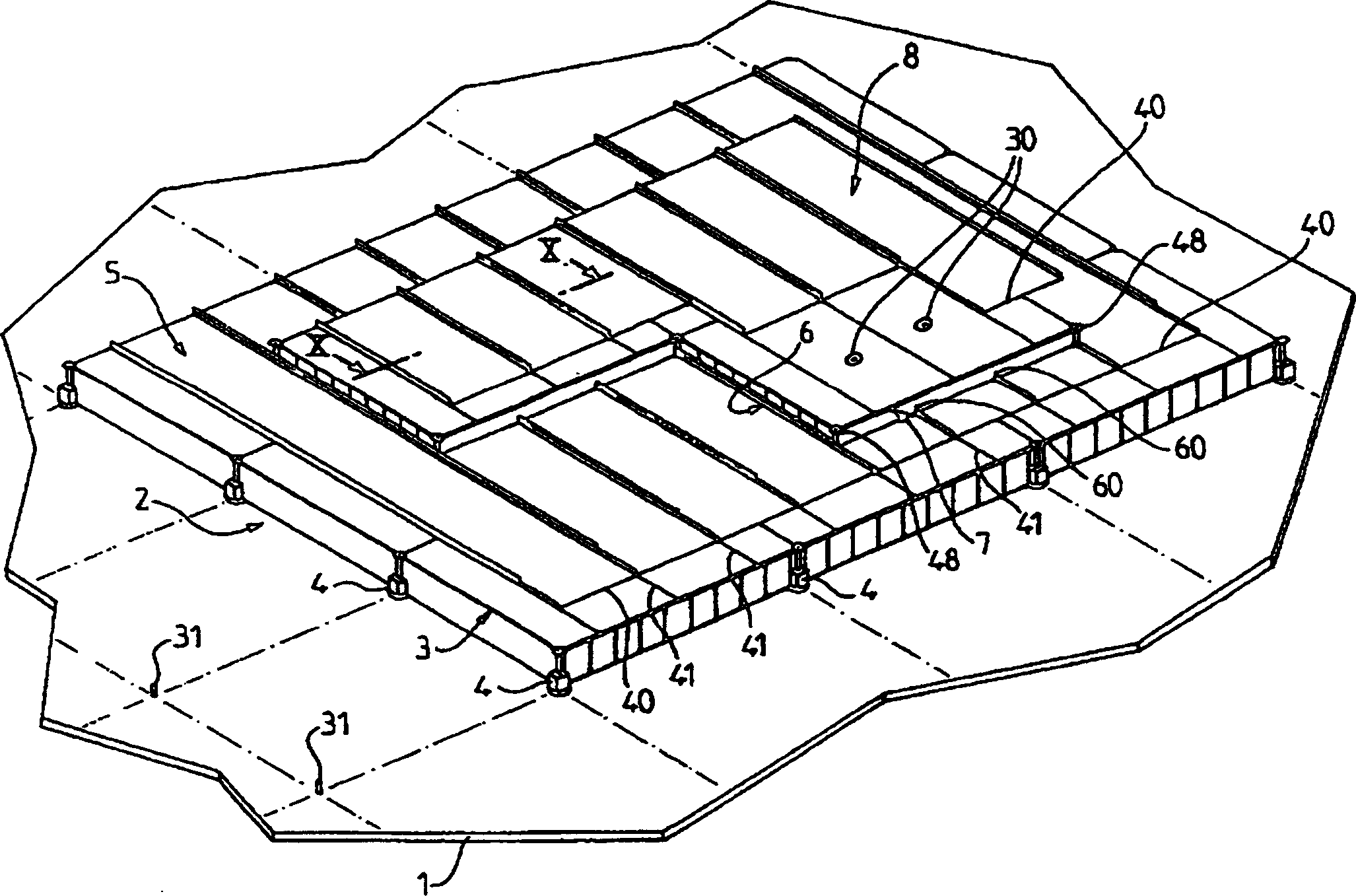

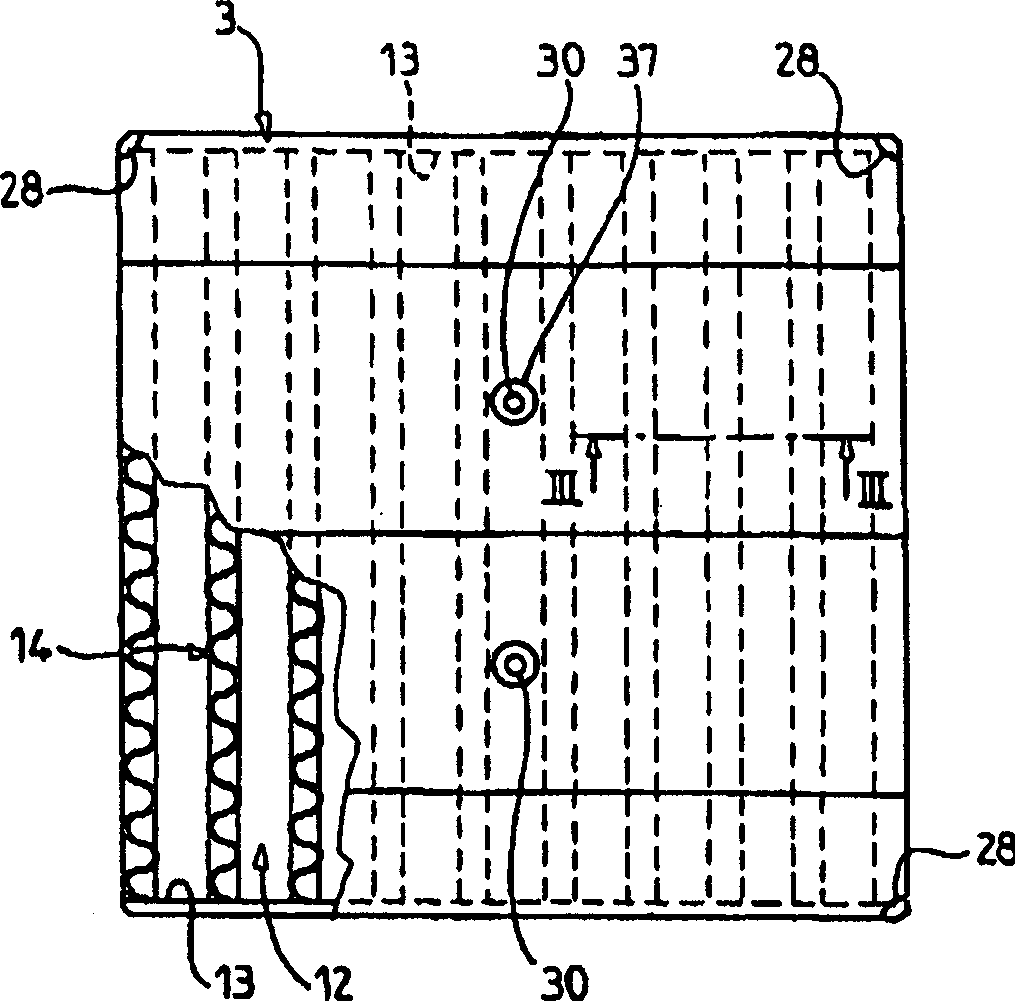

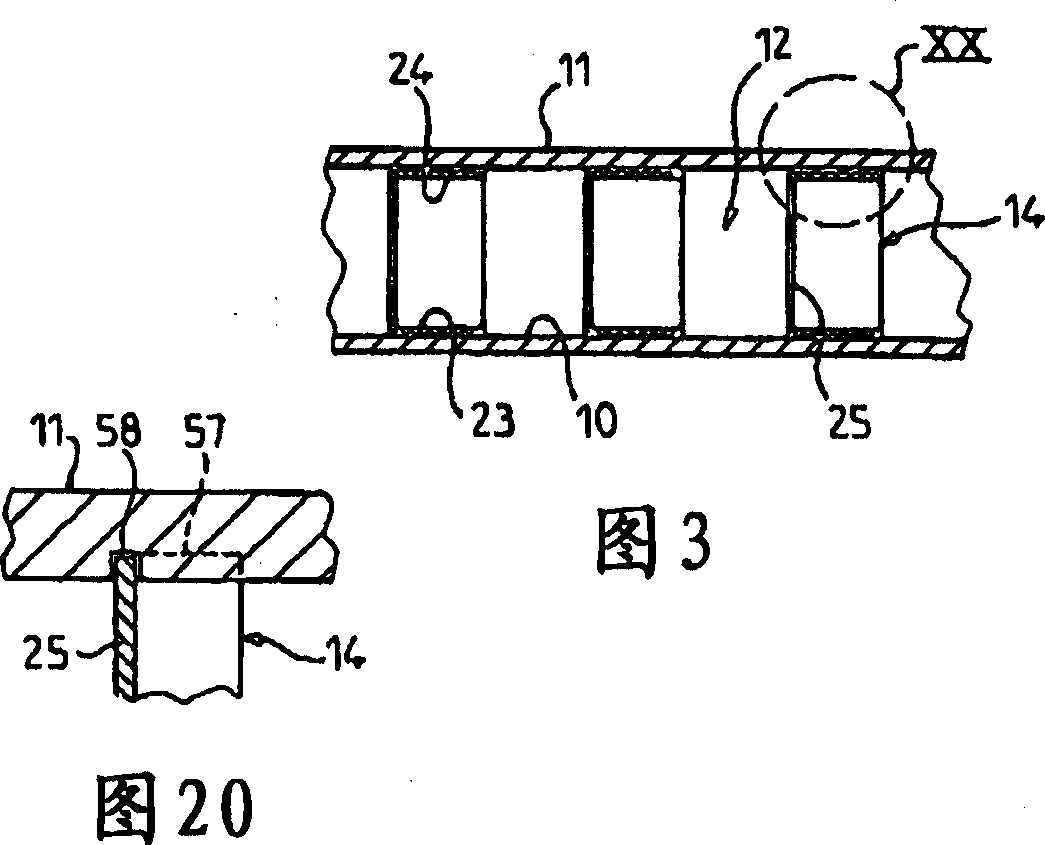

[0059]A description is given below of several embodiments of a hermetically insulated tank comprising and secured to the double hull of a component of a FPSO or FSRU type carrier or a methane carrier. The overall structure of such tanks is known per se and has a polyhedral shape. Therefore, only a description is given of the wall area of the tank, it being understood that all walls of the tank have a similar structure.

[0060] now refer to Figures 1 to 12 A description is given of an embodiment. figure 1 Denotes an area of the double hull of a ship marked with 1. The tank wall comprises in sequence along its thickness a second insulating barrier 2 formed by a watertight box 3 juxtaposed on the double hull 1 and fastened thereto by means of second fixings 4 , then by the waterproofing The second airtight partition 5 carried by the box 3, then the main thermal insulation partition 6 formed by the juxtaposed waterproof box 7 fixed on the second airtight partition 5 by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com