Centrifuge comprising hydraulic differential speed determination

A centrifuge, fixed speed technology, applied in the field of centrifuges, can solve the problem of damage to the rotary joint, and achieve the effect of avoiding volume loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

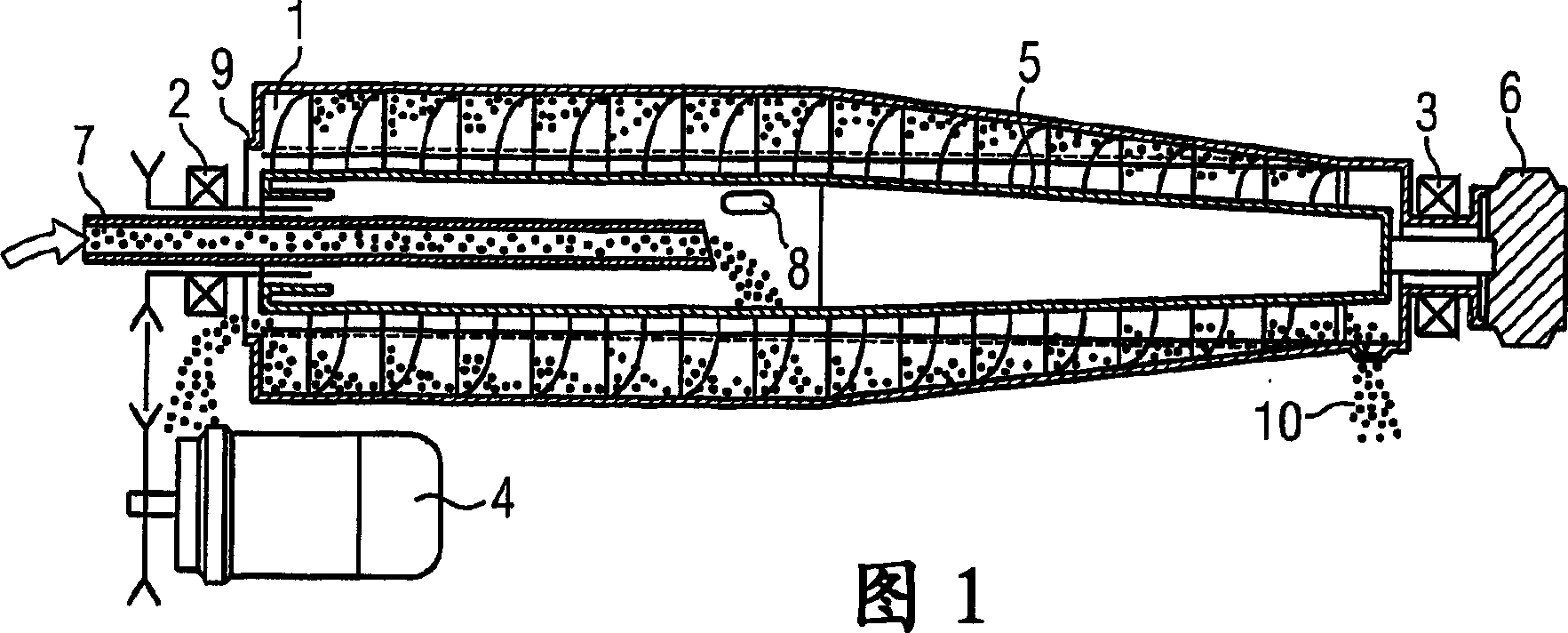

[0036]As shown in FIG. 1 , this machine generally comprises a drum 1 , which is rotated by means of bearings 2 and 3 and driven by a motor 4 ; a worm 5 coaxially located in the drum, said worm by means of a worm drive 6 Has a slightly different rotational speed than drum 5. Therefore, the worm rotates with a certain rotational speed difference relative to the drum. The product or solid-liquid mixture is fed via the outlet pipe 7 into the worm hub (Nabe), which reaches the separation chamber through the opening 8 and forms an annular pool here, the height of which is defined by the overflow protection 9 . The heavier phase (sediment) is deposited on the drum wall and is conveyed by the worm through the taper in the tank to the discharge opening 10, where it is thrown out.

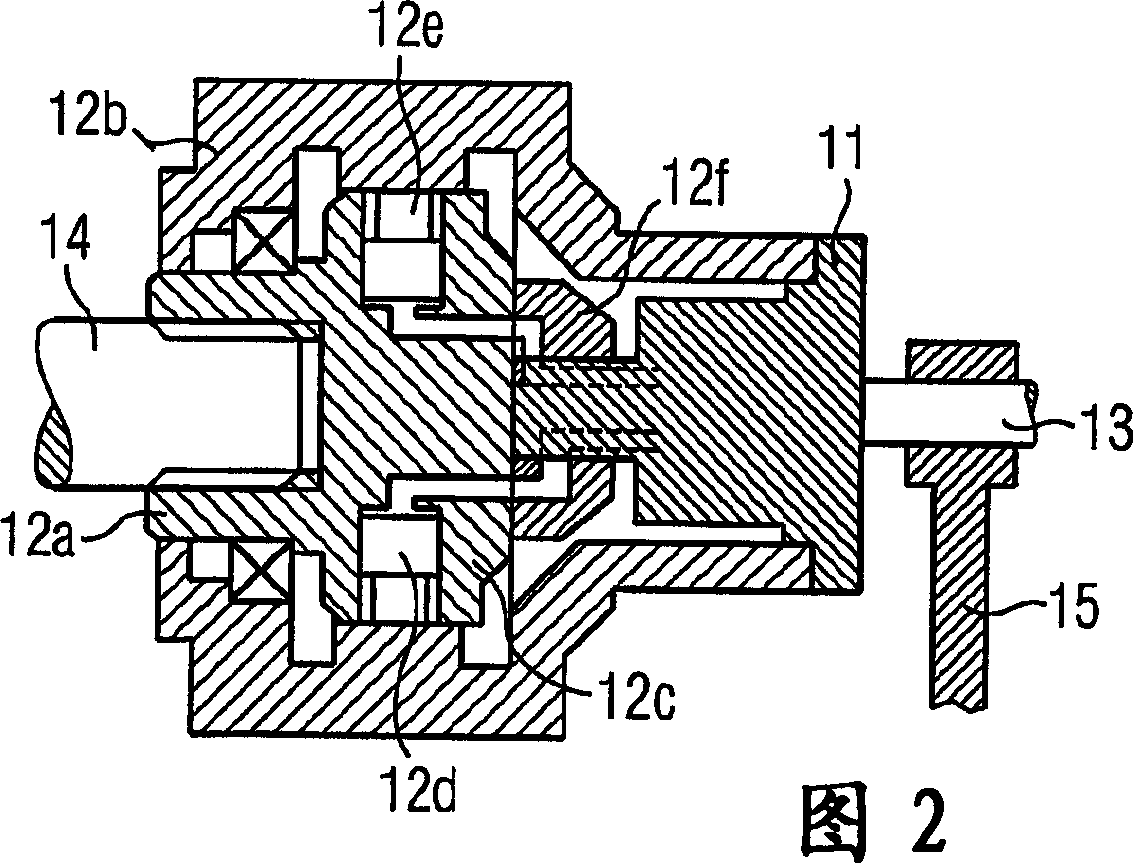

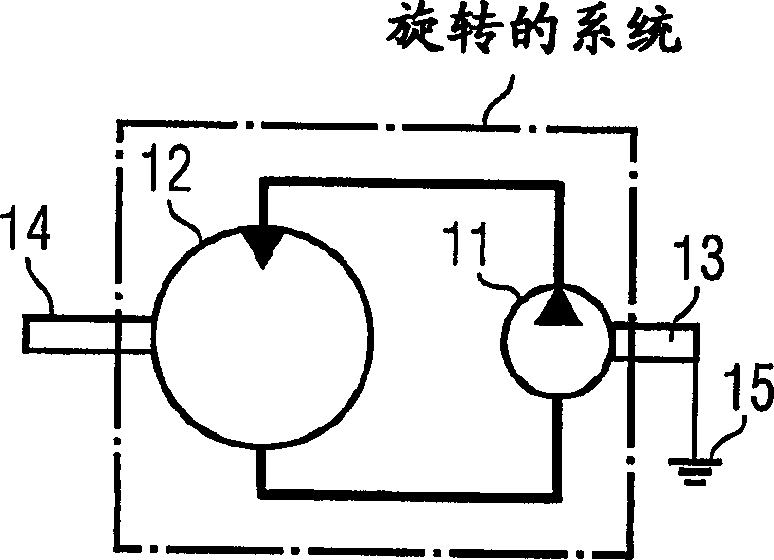

[0037] FIG. 2 shows a schematic diagram of such a drive. A multi-stroke radial piston machine is shown as an example of a high-torque hydraulic motor 12 . In its housing 12b, which is attached to the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com