Method for preventing idling and slipping of wheel of track motor car

A technology for motor vehicles and wheels, which is applied in the direction of wheels, wheel adhesion, vehicle components, etc., can solve the problems of high operating cost, complex system, and easy misoperation of system judgment, and achieve the effect of stable performance and simple structure of system devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

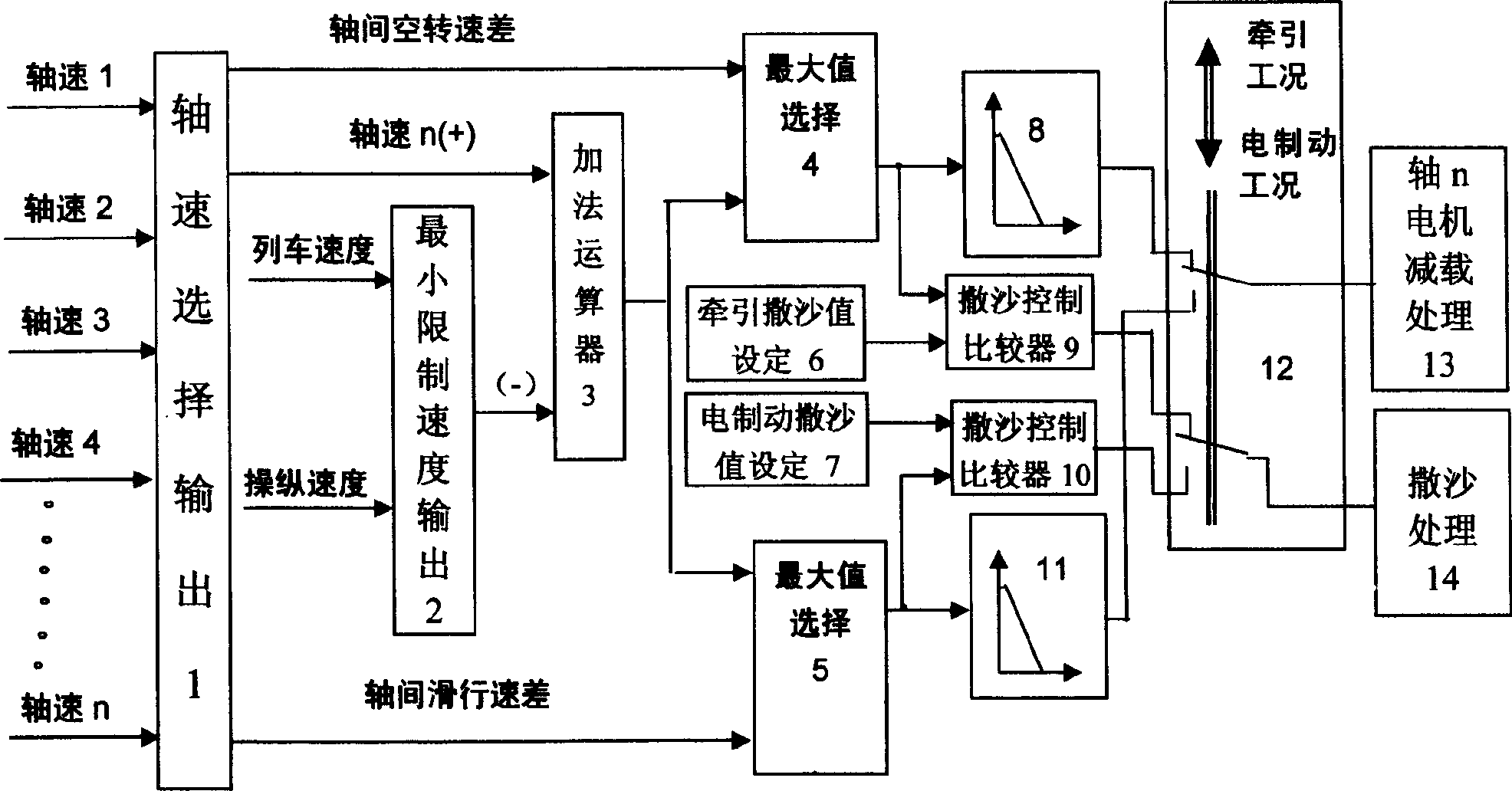

[0008] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0009] 1. Idling occurs in the traction condition. When the following situations occur, it is judged that the traction force of the shaft is reduced to 0, and the idling is about to occur or has already occurred. At this time, the idling is suppressed by power shedding or sanding.

[0010] 1. When the difference between the speed of a certain axis and the control speed of the driver reaches a certain value a;

[0011] 2. When the speed of a certain shaft exceeds the train speed and reaches a certain value a;

[0012] 3. When the speed of a certain shaft exceeds the speed of other shafts and reaches a certain value a.

[0013] Through experiments on specific application types, the corresponding a value is obtained as the idling threshold value of the load reduction calculation of the present invention.

[0014] 2. Sliding occurs in the braking condition. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com