Semiconductor-laser-pumped solid-state laser apparatus

A solid-state laser and semiconductor technology, applied in the direction of lasers, laser parts, phonon exciters, etc., can solve the problems of large power consumption, uneconomical power consumption, etc., achieve safe driving current switching, reduce energy consumption, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the semiconductor laser pumped solid-state laser according to the present invention will be described in detail below with reference to the drawings.

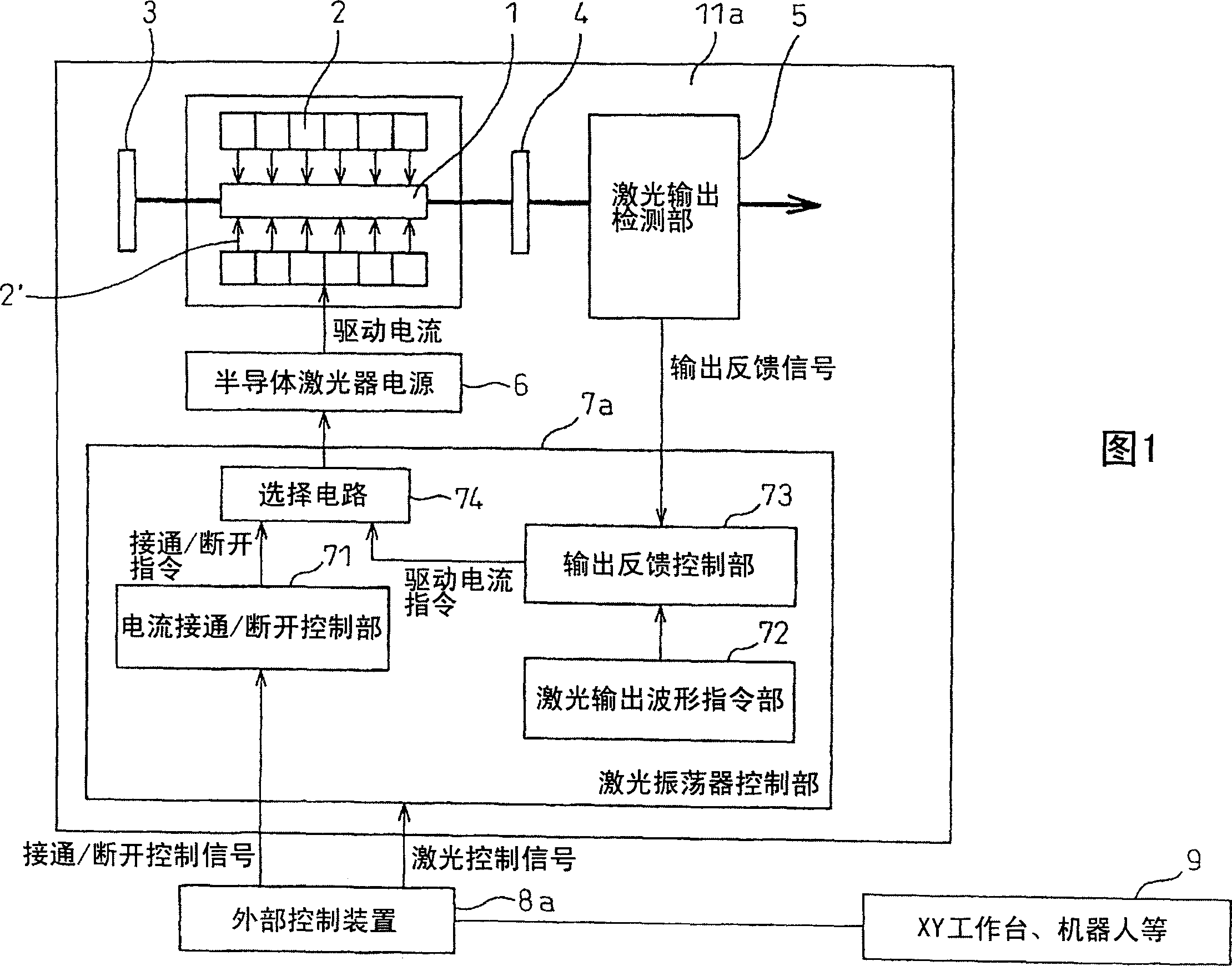

[0030] Fig. 1 is a block diagram showing the structure of a semiconductor laser pumped solid-state laser device according to Embodiment 1 of the present invention. In this figure, the structure of a semiconductor laser pumped solid-state laser device 11a is basically the same as that of the semiconductor laser pumped solid-state laser device 11 shown in FIG. 5, and the same reference numerals are attached to the same parts. In the present invention, the structure of the laser oscillation control unit 7a and the structure of the external control device 8 are different from those of the conventional ones.

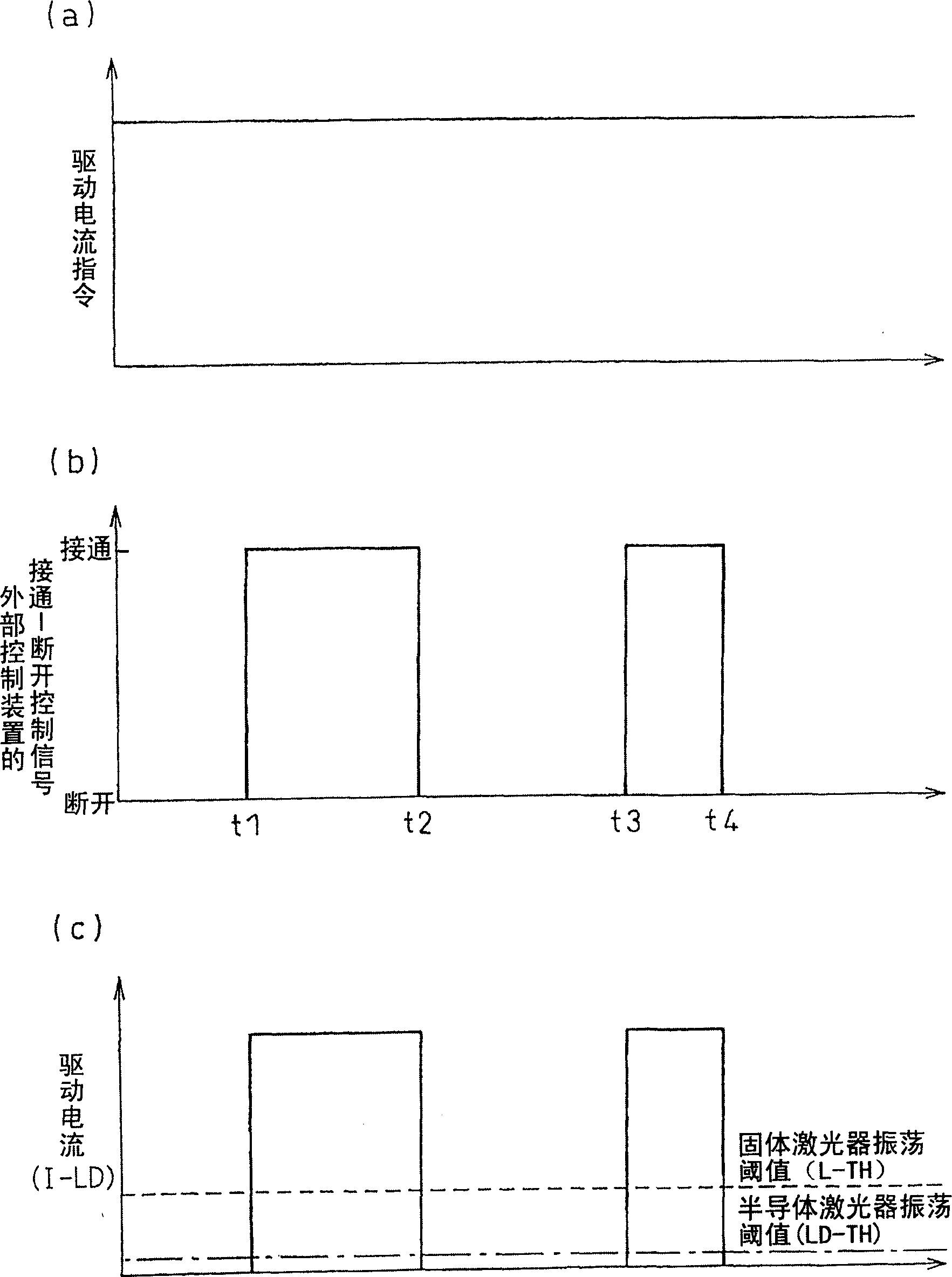

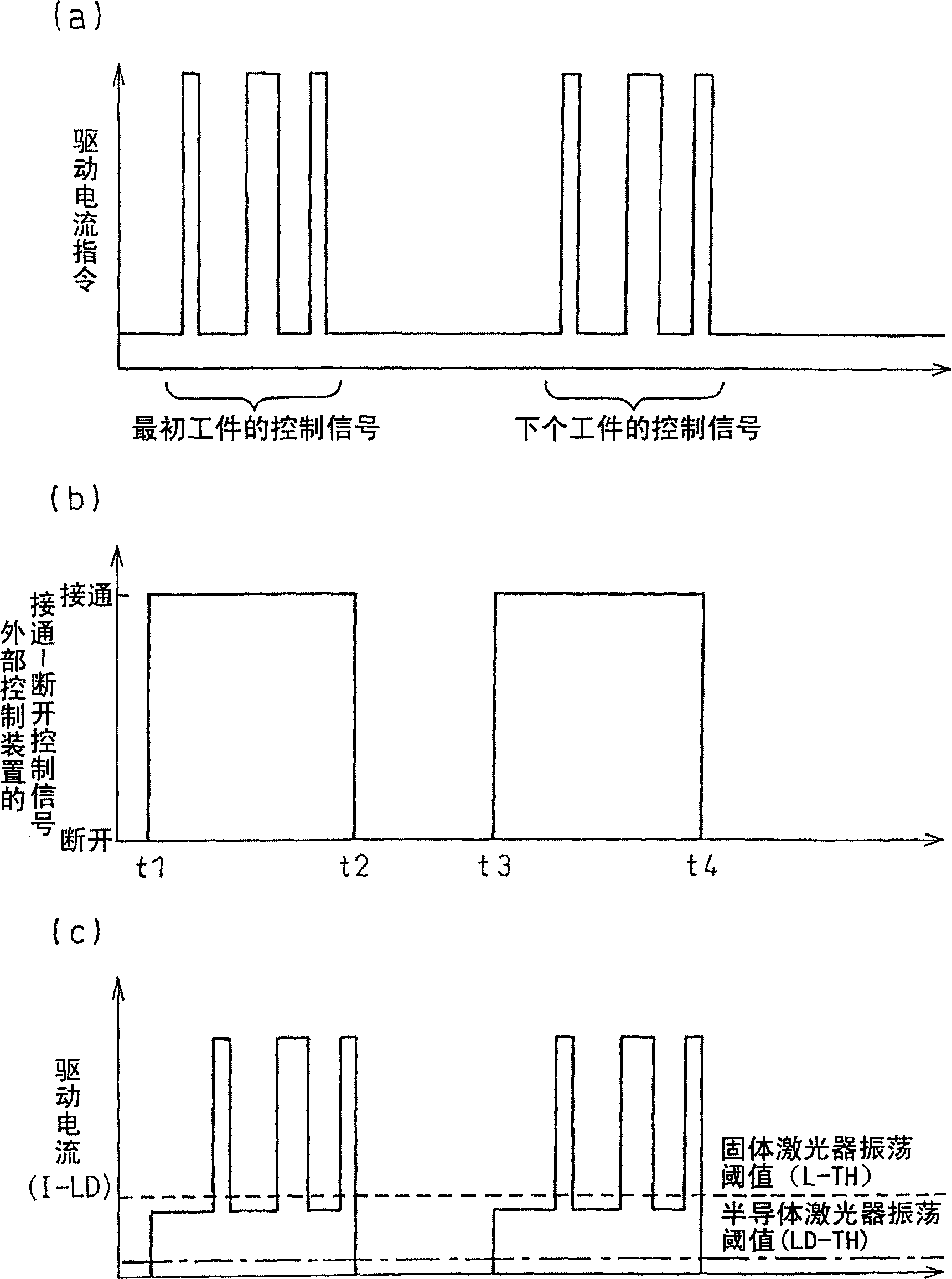

[0031] The semiconductor laser excitation solid-state laser device of this embodiment has: a current on / off control unit 71 that outputs an on / off command signal based on an on / off control signal output f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com