Plasma display assembly

A plasma display and component technology, applied in the field of invention of plasma display components, can solve the problems of increased power, complex structure, heating of the circuit and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

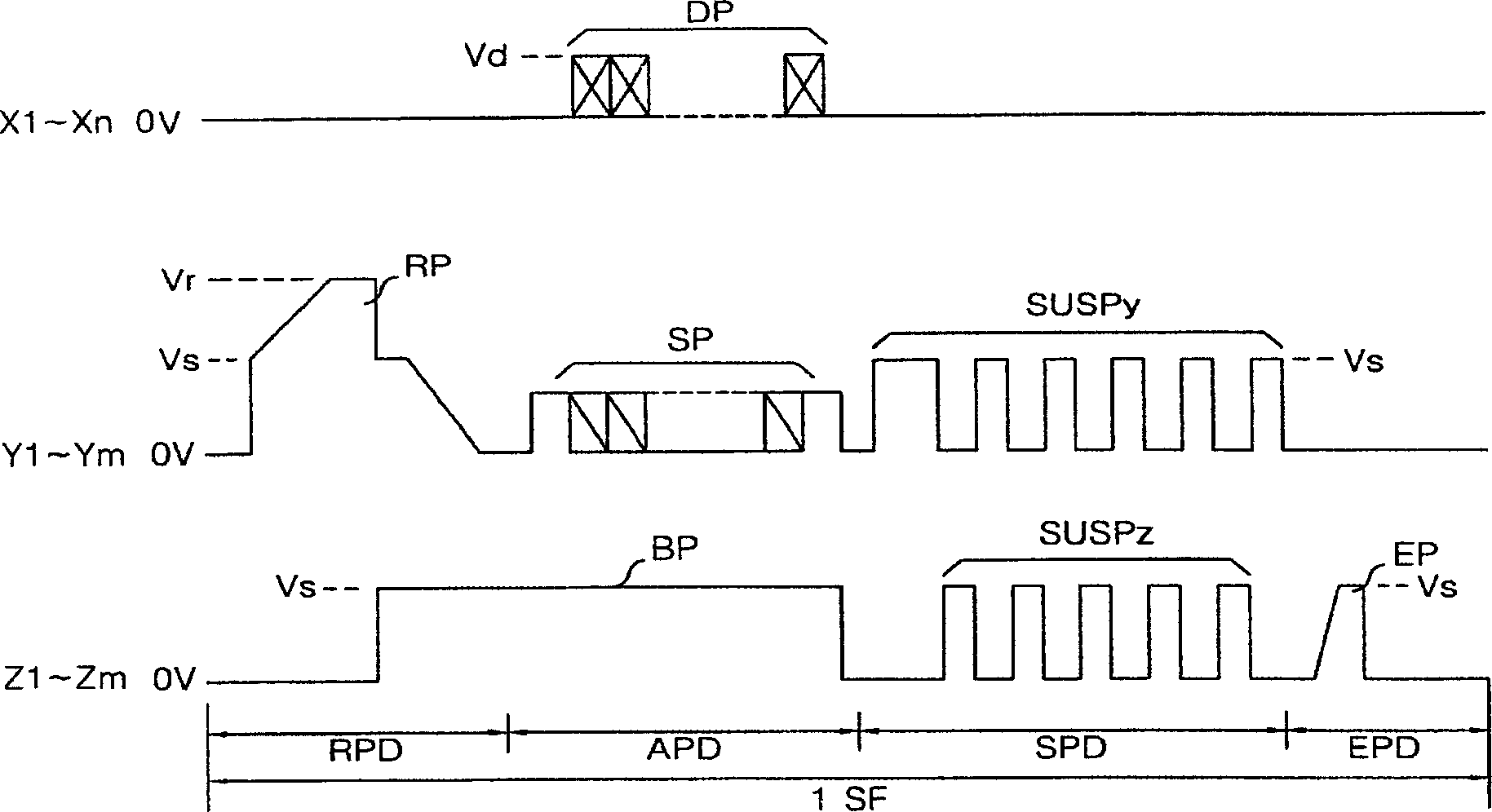

[0083] Refer to the following Figure 9 to Figure 14 Embodiments of the plasma display unit of the present invention will be described in detail.

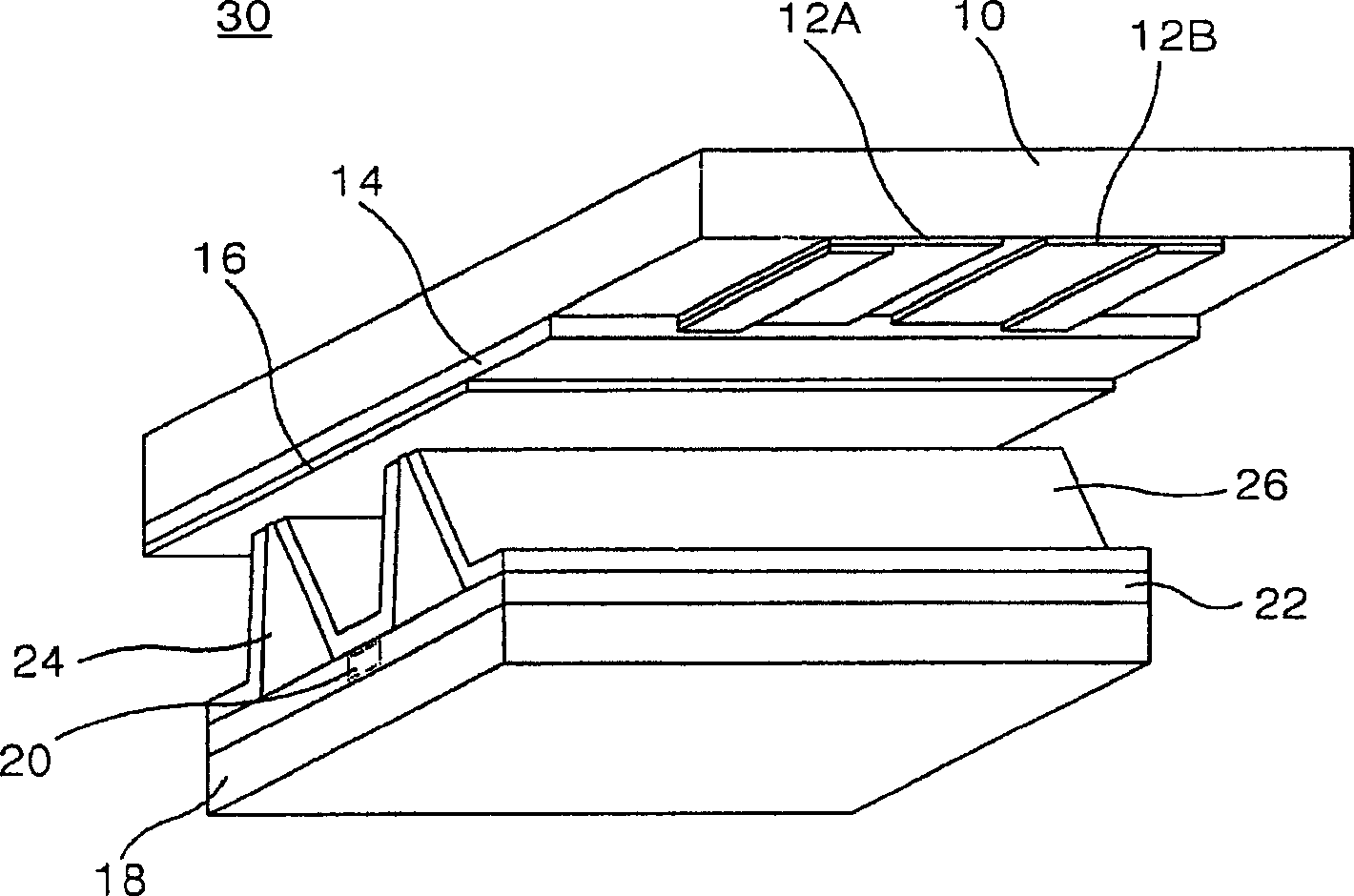

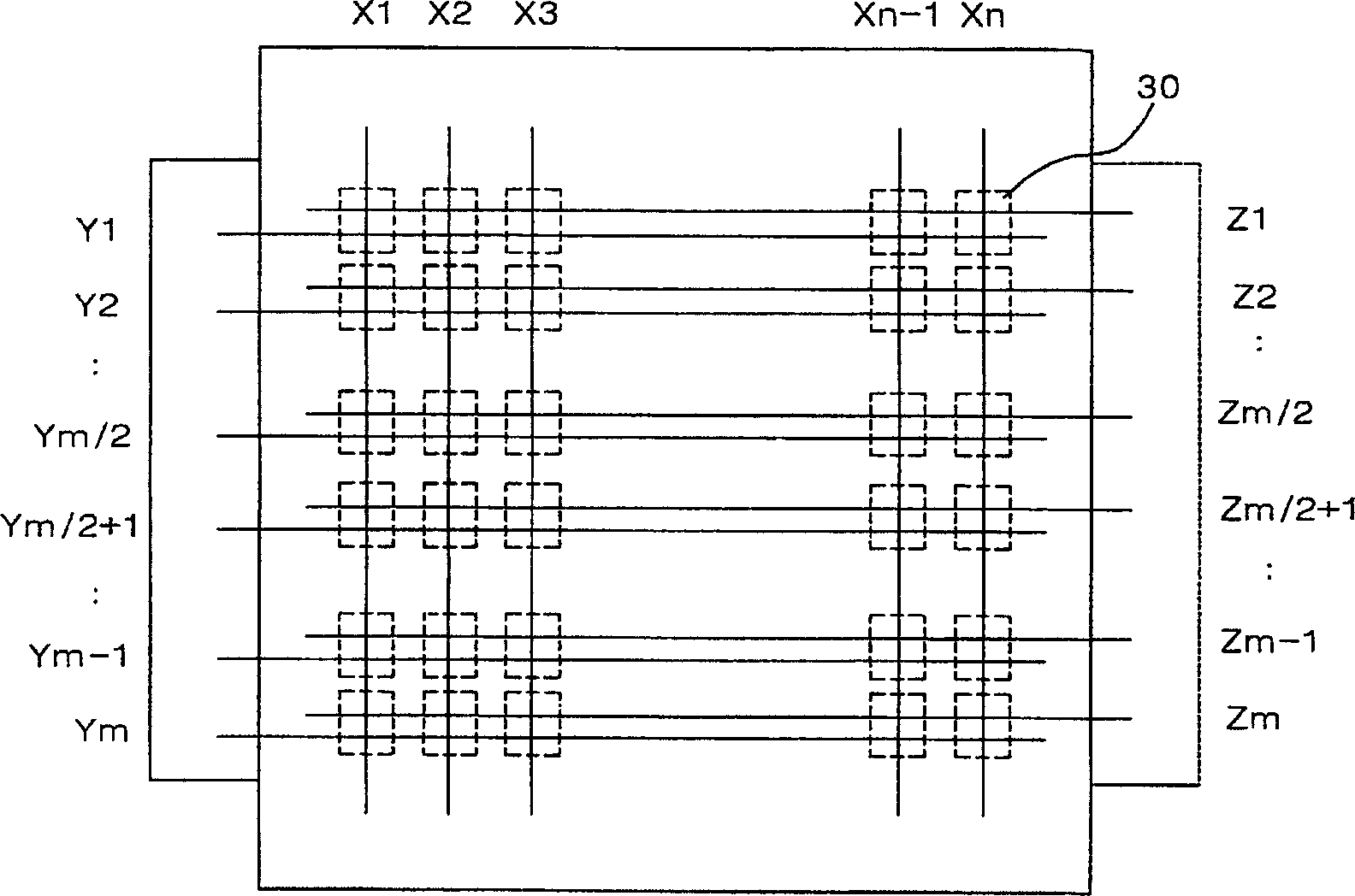

[0084] Figure 9 is a schematic diagram of a plasma display according to an embodiment of the present invention; Figure 10 is like Figure 9 Schematic diagram of the cross-sectional configuration of the plasma display assembly shown.

[0085] Figure 9 and Figure 10 The composition of the PDP assembly shown includes: a heat release pipe 86 arranged on the back of the PDP70; a Y-Z integrated board 100 arranged on the back of the heat release pipe 86; a data driver board 80; a control board 72; A power board (not shown in the figure) of the power supply; a transmission printed circuit board (Printed Circuit Board: PCB for short).

[0086] In the PDP 70, the front glass plate 90 and the rear glass plate 92 have a gas discharge space and have a connected structure. Here, in the front glass plate 90 such as figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com